Furniture Quality Inspection: Standards and Checklists

Furniture has to meet the specific quality, safety, durability, and packaging requirements and standards when it comes to the end users. A high-quality inspection method ensures your products are checked for against all specifications to ensure that the regulations and requirements are met. Enabling corrections to be actioned and implemented before completion, reduces the risk of production failure and helps to verify the material, manufacturing and finishing quality and therefore reduces the risk of after-sale services due to production defects.

Furniture refers to beds, tables, desks, sofa, chairs, and cabinets which are made from materials like wood, plastic, glass, marble, or pine. Furniture manufacturers and brands are working continuously to bring comfort, style, and functionality together to provide an ultimate user experience. The quality and safety of furniture is as critical as its style and function when it comes to the consumer.

To bring furniture to the market, the buyers and exporters must guarantee your furniture is manufactured compliance regulations and standards which are designed to protect consumers from hazards. Furniture inspections including outdoor furniture inspection, sofa inspection, reduce risks, avoid recalls, improve the quality of the furniture and helps to manage the quantity of raw materials used to manufacture the finished product.

In this article, we will talk about the types of third-party furniture inspection, the standards of the furniture safety, and the pre-shipment inspection checklists for furniture products.

Third-party Furniture Quality Control Inspection Service

Furniture inspection is a crucial step in the manufacturing and distribution of furniture products like tables, chairs, and outdoor furniture, which play an essential role in consumers’ everyday lives, designed to ensure that the items meet the required quality standards and safety regulations.

It involves a comprehensive and detailed check of various aspects of the furniture to identify any defects or issues that need to be resolved before the shipment. Conducting indoor furniture and outdoor furniture inspections enable you to hold your suppliers accountable and uphold a good brand reputation.

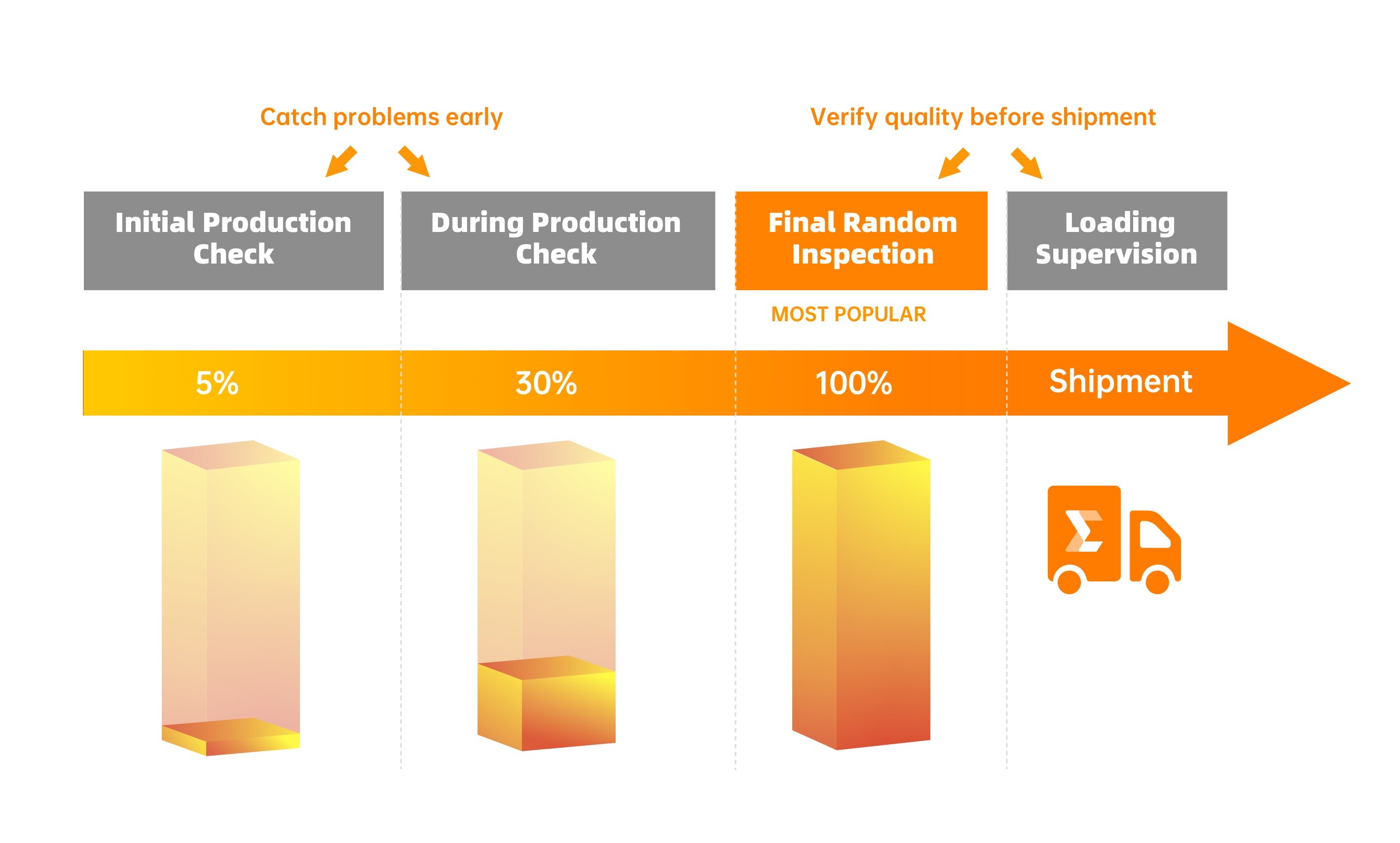

Different types of inspections are performed at various stages of the manufacturing process. These include:

Initial Production Check (IPC) – A visual check on the quality of pre-series furniture at the beginning of production, against the clients’ specifications, technical drawings and type sample.

During Production Check (DUPRO) – A check on the dimensions of components, quality of materials and finished products during manufacturing

Final Random Inspection (FRI), also called Pre-shipment Inspection – A detailed visual inspection on randomly selected finished products. It takes place when the merchandise is completed, packed and ready for shipment. The quantity, workmanship, function, color, size specifications safety test, and packing details are verified to ensure that the contract specifications are met.

Loading Supervision (LS) – Supervised loading of containers to ensure that the goods checked via a Final Random Inspection are those shipped to the intended recipient.

Regulations and Standards for Furniture Quality Control

Furniture quality control inspection is virtual to ensure that products meet the necessary standards, providing customers with safety furniture. These standards cover a wide range of aspects, including material specifications, structural integrity, surface finish, safety requirements, and performance testing.

Adhering to these standards ensures that furniture products are safe, reliable, and compliant with industry best practices. Manufacturers, brands, and importers who prioritize furniture quality control based on these applicable standards can offer products that meet customer expectations, enhance brand reputation, and contribute to a positive and trustworthy market presence.

Furniture Compliance Requirements in the US

ASTM International’s standards are designed to improve product quality, enhance safety, facilitate market access and trade, and build consumer confidence in the US.

- ASTM F1561 Standard Performance Requirements for Plastic Chairs for Outdoor Use

- ASTM F2057 Standard Safety Specification for Clothing Storage Units

- ASTM F2613 Standard Consumer Safety Specification for Children's Chairs and Stools

- ASTM F1838 Standard Performance Requirements for Adult and Children’s Plastic Chairs for Outdoor Use

- ASTM F404 Standard Consumer Safety Specification for High Chairs

- ASTM F1427 Standard Consumer Safety Specification for Bunk Beds

Furniture Regulations and Standards in the EU

The GPSD applies to all consumer products being sold in the EU to ensure the product is safe and does not pose a risk to consumers.

The following are referenced standards that relate to different categories of furniture:

- EN 12520 Furniture - Strength, durability and safety - Requirements for domestic seating

- EN 12521 – Furniture. Strength, durability and safety. Requirements for domestic tables

- EN 1335 Office furniture - Office work chair

- EN 16139 Furniture - Strength, durability and safety - Requirements for non-domestic seating

- EN 1022 Furniture - Seating - Determination of stability

- EN 1728 Furniture - Seating - Test methods for the determination of strength and durability

- EN 13759 Furniture - Operating mechanisms for seating and sofa-beds - Test methods

- EN 581-1 – Outdoor furniture – Seating and tables for camping, domestic and contract use – Part 1: General safety requirements

- EN 716 Furniture – Children’s cots and folding cots for domestic use

- EN 1129 Furniture – Foldaway beds – Safety requirements and testing

- EN 16890 Children’s furniture – Mattresses for cots and cribs – Safety requirements and test methods

- EN 15372 Furniture. Strength, durability and safety. Requirements for non-domestic tables

- EN 1130 Furniture – Cribs and cradles for domestic use

- EN 1729 Furniture – Chairs And Tables For Educational Institutions

- EN 1725 Furniture - Beds - Requirements for safety, strength and durability

- EN 747 Furniture - Bunk beds and high beds-Safety, strength and durability requirements

Pre-shipment Inspection Checklists for Furniture

The importers and brands employ reliable third-party quality control Inspection Company to ensure the safety of furniture supply chain. Inspected furniture can contribute to increased consumer confidence in associated products and can help to strengthen brand reputation among both consumers and retailers.

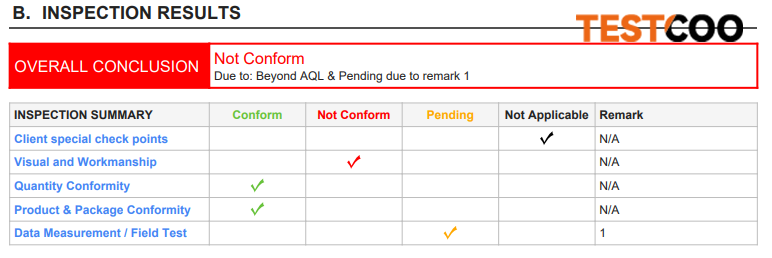

In most cases, a pre-shipment inspection is performance to meet requirements of the buyers. An on-site inspector focuses on these four checklists: visual and workmanship, quantity, product and package, data measurement and field test.

A furniture inspection checklist includes:

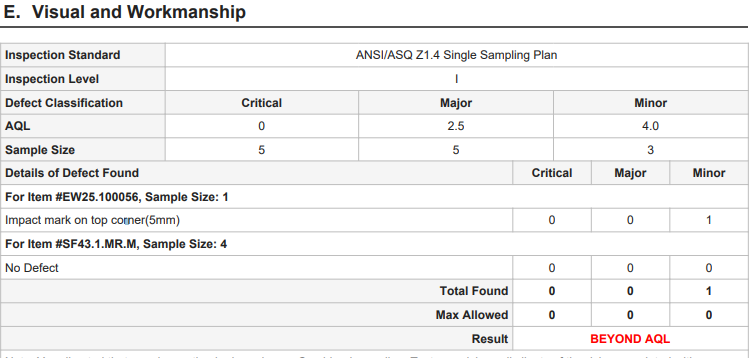

1. Visual and Workmanship Check

If no specific requirement from applicant, the inspector will visually inspect the exterior and interior parts of the furniture using inspection sampling plan, General Inspection Level II, AQL 1.5. 4.0.

They’ll check for the following aspects, including: appearance and aesthetic of the goods, fabric, printing, painting, gaps, screw holes, hardware, glass, plastic, mirror and foam.

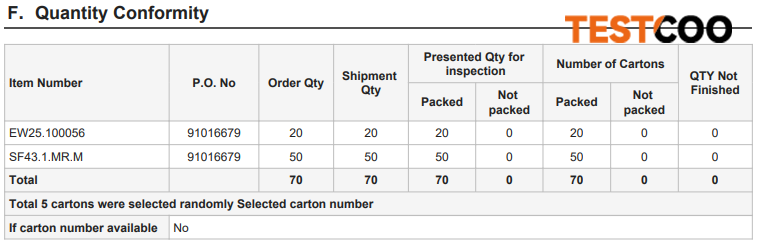

2. Quantity Check

Discrepancies in batch quantities can cause confusion, delays, and inventory tracking issues. The inspection team conducts a thorough count and cross-checks of furniture ready to be delivered against purchase order documentation.

They compare the shipment’s quantity to the specified order quantity, ensuring precise alignment between the two. This meticulous process guarantees accurate documentation and facilitates smooth inventory management.

3. Product and Packaging Check

The product and packaging conformity service in TESTCOO final random inspections for furniture includes an evaluation of the labeling and packaging aspects of the products. Reviewing the presence and accuracy of the Purchase Order, Product Specification, and User Manual.

These documents provide essential information about the product, its specifications, usage instructions, and any other specific requirements requested by the client. Besides TESTCOO will review other specific questions around the documentation provided by the client. It includes the next items:

- Product Appearance Verification

- Accessories Verification

- Packing Verification

- Labling/ Marking Compliance

4. Data Measurement and Field Test Checklist

- Carton drop test

- Carton size and weight measurement

- Product size and weight measurement

- Metal detection check

- Barcode scan check

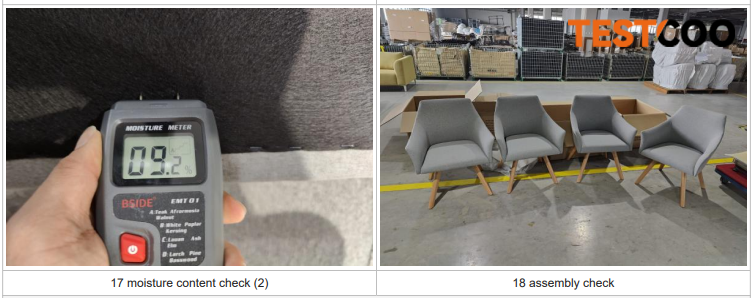

- Assembly check

- Function check

- Moisture check for wood component

- Coating adhesive Tape Test

- Static loading check

- Stability check

- Wobbling Test for Free Standing or Assembled product

- Color fastness check

- Vertical static loading

- seat impact test

- Breaking test for tempered glass

- Smell check

Check a furniture inspection checklist template: https://www.testcoo.com/en/sample-report

Furniture Inspection Report

Furniture inspection reports should be as detailed as possible and include:

Inspection Information – clients name, suppliers’ information, product name, inspection date, inspector’s name, factory, quantity, location and the name of the staff member the product was reviewed by

Inspected articles –two photos of the product.

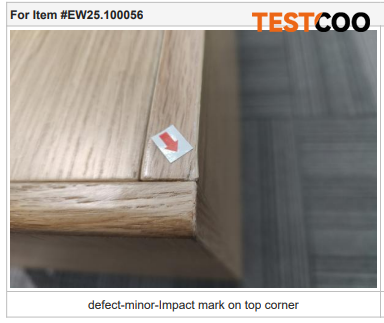

Inspection Standard – inspection type, default levels, specify defects and level the defect by critical, major or minor categories.

Inspection Result – score the quantity, visual and workmanship, data measurement, packaging and shipping mark by ‘conform’, ‘not conform’ or ‘pending’.

Remark Points –attach any defect pictures with an explanation

Quantity Status – include the item types, shipment quantities, packed quantities and non-packed quantities

Packing Method – attach pictures of the packaging and shipping marks.

Product Conform-Check the appearance, accessories against approval sample or the document provided by clients.

Data Measurement – score each section using conform’, ‘not conform’ or ‘pending’ and include the detailed measurements of each product.

Field Test-According the checklist, perform all the test, including moisture check, stability heck, static loading check and other more. Attach all the test pictures. Additional Information – include any extra important information or pictures, including the factory gate, other document.

Additional Information – include any extra important information or pictures, including the factory gate, other document.

TESTCOO is your Certified Furniture Inspection Provider in China, Vietnam, India and Bangladesh

Comprehensive Inspections

TESTCOO Inspection conducts comprehensive Initial production, during production, and pre-shipment inspections, following the AQL standards, leaving no room for subpar products to slip through the cracks.

Detailed Reports with Digital Evidence

Our furniture Inspection report comes with digital evidence, enabling efficient identification, categorization of defects and recommendations. WithTESTCOO Inspection, you can expect timely and detailed inspection reports, allowing you to take prompt action if any issues arise.

Customizable Solutions

Understanding that different companies have unique requirements, TESTCOO Inspection offers customizable inspection solutions that align with your specific quality standards.

Global Coverage

TESTCOO Inspection has a strong network of 500+ qualified inspectors located in 30 countries, China, Vietnam, Bangladesh, Cambodia, India, Indonesia , Myanmar, Pakistan, Turkey... catering to diverse clients and industries.

Data Analysis Report for your Furniture Suppliers Management

You can use our global big data intelligent analysis system to management your supply chain.

Sourcing across Asia is not without communication and language barriers, with Vietnam, India and China fast becoming a popular destination for furniture manufacturing due to the low costs. Using TESTCOO, a professional third-party quality provider, who has the expertise in inspection and sourcing can ensure you will receive the best, top-quality products, as product specifications can be communicated correctly and clearly.

By employing an independent inspection and testing partner like TESTCOO, quality concerns will be identified and controlled at the very source.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index