The Ultimate Guide to the Bill of Materials (BOM): The Blueprint of Modern Manufacturing

In the intricate world of manufacturing, from crafting a simple ballpoint pen to assembling a sophisticated electric vehicle, there exists a foundational document that serves as the single source of truth: the Bill of Materials, or BOM. The BOM is far more than a mere shopping list; it is the product's DNA, a comprehensive blueprint that details every single component, sub-assembly and raw material required to bring a finished product to life.

This article, an expansion of the fundamentals, will take a deep dive into the world of the BOM. We will explore its detailed structure, dissect its various types, understand its critical importance across business functions and outline the best practices and challenges in its management.

What is a Bill of Materials (BOM)? A Deeper Definition

A Bill of Materials (BOM) is a hierarchical and exhaustive list of all the items needed to manufacture a product. It specifies the part numbers, part names, descriptions, quantities and units of measure for everything from screws, resistors and raw plastics to complex printed circuit board assemblies (PCBAs) and custom-machined housings.

Think of it as the ultimate recipe. If you were baking a cake, the BOM would not only list flour, sugar and eggs but would also specify the type of flour, the exact weight of sugar, the number of eggs, and even the pre-assembled components like "frosting mixture." In manufacturing, this precision is paramount. A single error in the BOM; a wrong part number or an incorrect quantity can ripple through the entire production process, causing costly delays, product failures and significant financial losses. This document acts as the primary communication tool between engineering, procurement, manufacturing and inventory management departments ensuring everyone is working from the same accurate script.

Related Article:Resilience in Supply Chain Management

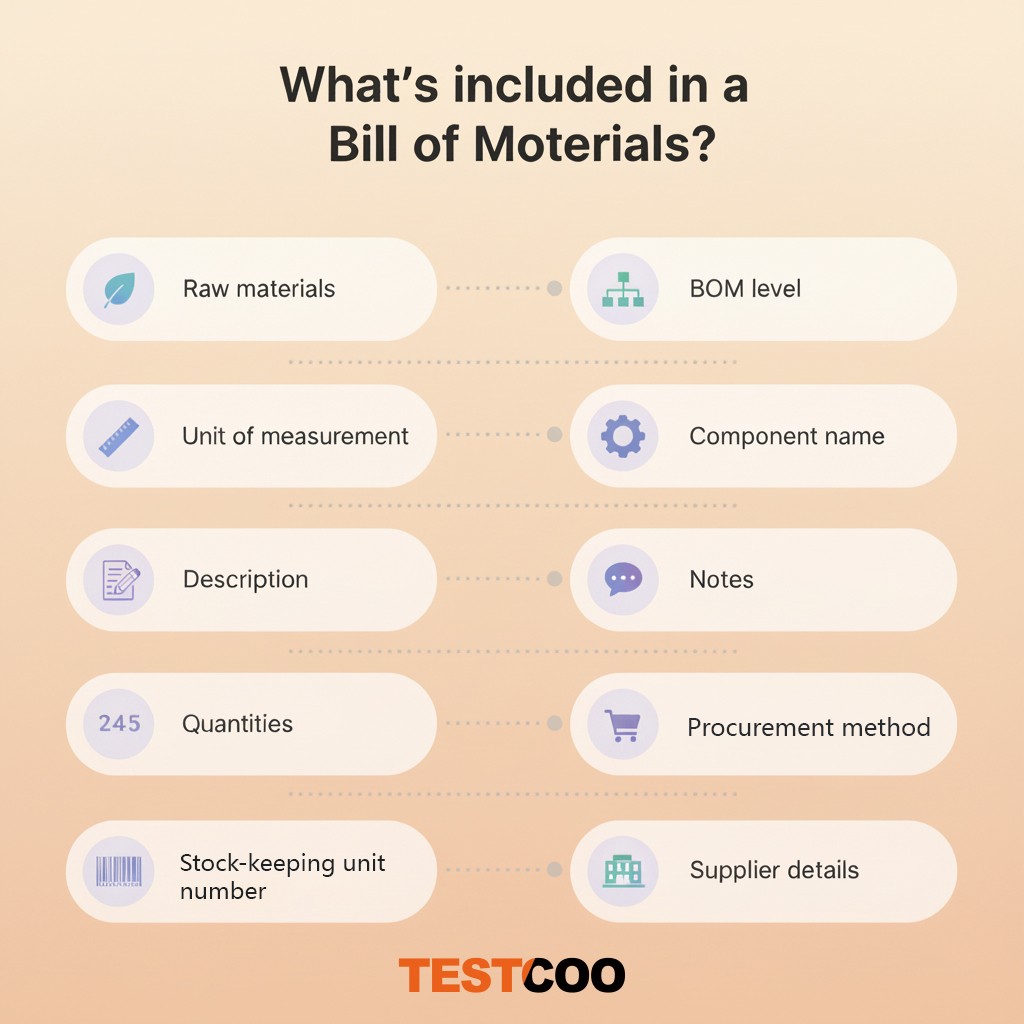

What key information or data fields should be included in a comprehensive BOM?

A well-structured BOM contains several critical data fields. While the exact format can vary, a comprehensive BOM will typically include:

- BOM Level: This number assigns a rank to each part or assembly in the hierarchy, helping to illustrate the product's structure. The final product is typically Level 0.

- Part Number: A unique numerical or alphanumeric code assigned to each specific part. This is crucial for eliminating ambiguity.

- Part Name: A unique, descriptive name for the part.

- Description: A more detailed description to help distinguish the part from similar items.

- Quantity: The number of units of a specific part required for one single assembly or sub-assembly.

- Unit of Measure: The unit in which the part is used or purchased (e.g. "each," "feet," "kilograms," "liters").

- Procurement Type: How the part is acquired, such as "off-the-shelf," "made-to-spec" or "in-house production."

- Reference Designators: Used in electronics, these explain where specific components fit on a printed circuit board (e.g. C1, R5, U2).

- BOM Notes: Additional, relevant information, such as preferred suppliers or specific handling instructions.

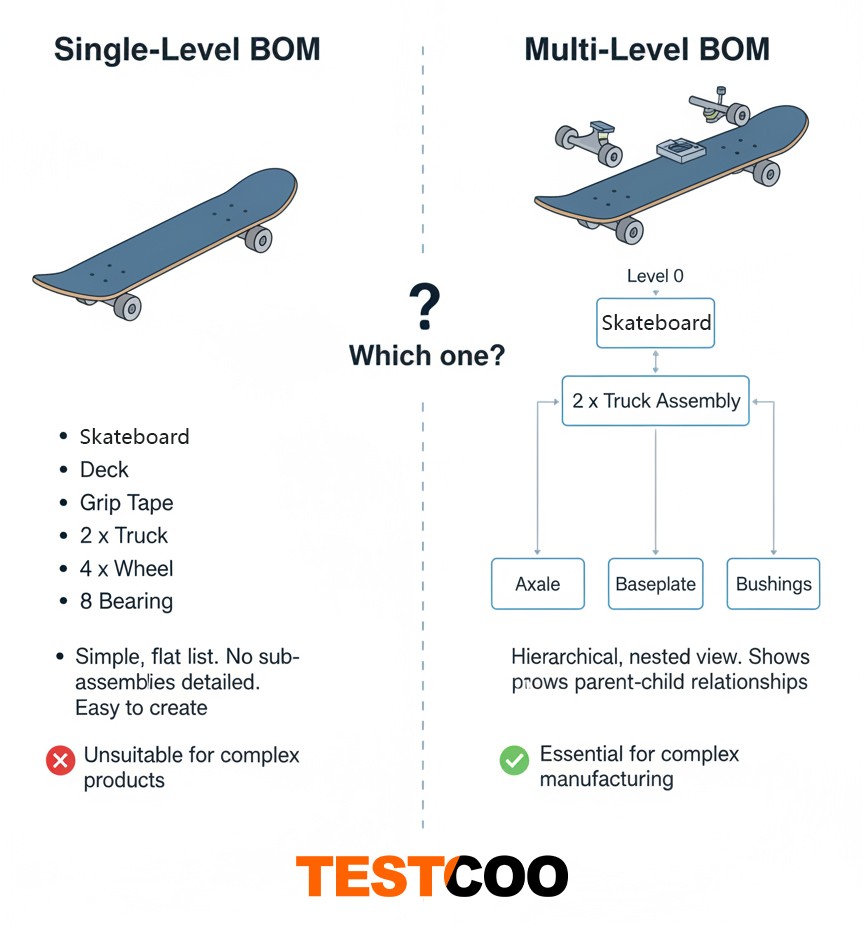

What is the difference between a single-level and a multi-level BOM structure?

BOMs are typically structured in one of two ways, each serving a different purpose.

- Single-Level BOM: This is the simplest form, presenting a list of all components required for a product without detailing any sub-assemblies. It's often referred to as a "flat BOM." For a simple product like a skateboard, a single-level BOM would list the deck, grip tape, two trucks, four wheels and eight bearings. However, it wouldn't show that the trucks are themselves assemblies of axles, bushings, and baseplates. This structure is easy to create but unsuitable for complex products.

- Multi-Level BOM: This structure shows the hierarchical parent-child relationships between components and sub-assemblies. It provides a detailed, nested view of the product's architecture. Using the skateboard example, a multi-level BOM would show the final product at the top (Level 0). Below it (Level 1) would be the deck, grip tape and two "truck assemblies." Then, under the "truck assembly" (Level 2), it would list the axle, baseplate and bushings. This granular detail is essential for complex manufacturing, enabling accurate planning and costing.

↵ ↵

Are there different types of BOMs for different business departments?

As the source article mentioned, BOMs are adapted for different business departments. The main types include:

- Engineering BOM (EBOM): Developed during the product design phase, the EBOM is created by engineers often using data from CAD (Computer-Aided Design) software like those from Autodesk or Dassault Systèmes. It is structured based on the product's design and reflects its functional components. The EBOM is the foundation from which all other BOM types are derived.

- Manufacturing BOM (MBOM): The MBOM contains all the information needed to actually build the product. It is derived from the EBOM but includes not only the product components but also all the materials required for the manufacturing process itself such as consumables (glues, wires, fasteners) and packaging materials. The MBOM is structured to reflect the specific assembly line and production steps making it the primary guide for production planners and the procurement team.

- Sales BOM (SBOM): This BOM defines a product as it is sold. It lists the finished products and components that a customer will see on their order. The SBOM is crucial for configurable products. For example, when a customer orders a laptop, the SBOM would list the final laptop model along with selectable items like an upgraded power adapter or an optional carrying case which may be shipped as separate items in the same box.

Beyond these, other specialized BOMs exist:

- Configurable BOM (CBOM): Used for products with multiple options and variations like automobiles. The CBOM includes all possible components for a product family and uses rules to create a unique final BOM based on the customer's selected configuration (e.g. engine type, color, interior).

- Service BOM: A list of parts and assemblies needed to service, repair or maintain a product after it has been sold. This is used by service technicians to order replacement parts and ensure long-term product support.

Why the BOM is the Backbone of Manufacturing?

The importance of a meticulously maintained BOM cannot be overstated. Its impact is felt across the entire organization.

- Accurate Cost Calculation: The BOM is the foundation of product costing. By rolling up the costs of every single component and sub-assembly, businesses can accurately determine the material cost of a finished product. This informs pricing strategies, budget forecasting and profitability analysis.

- Streamlined Procurement and Inventory Management: The BOM directly feeds into Material Requirements Planning (MRP) systems, which are often a core component of larger Enterprise Resource Planning (ERP) systems. The MRP system uses the BOM to calculate precisely which raw materials are needed and when automating purchase orders and preventing both costly production shutdowns from material shortages and excessive capital being tied up in overstocked inventory.

- Efficient Production Planning: The MBOM provides the roadmap for the production floor. It dictates which components are needed at which assembly station ensuring a smooth and efficient workflow. This prevents confusion and errors during assembly leading to higher throughput and better quality.

- Ensuring Quality and Consistency: A standardized BOM guarantees that every unit of a product is built with the exact same approved components. This consistency is the bedrock of quality control ensuring the product performs as designed and meets customer expectations every time.

- Regulatory Compliance and Traceability: In regulated industries like aerospace, medical devices and automotive, the BOM is a critical tool for traceability. It provides a detailed record of every component which is essential for safety audits, recalls and proving compliance with industry standards like those set by the International Organization for Standardization (ISO).

Read more: Quality Check in Manufacturing: A Step-by-Step Guide for Global Buyers

What are the best practices for effectively creating and managing a Bill of Materials?

Given its importance, managing the BOM requires a disciplined and systematic approach.

- Establish a Centralized System: Avoid managing BOMs in scattered spreadsheets which is a recipe for disaster. Use a centralized system like a Product Lifecycle Management (PLM) or ERP platform to act as the single source of truth.

- Implement Formal Change Management: Products evolve. When a design change occurs, it must be formally documented through an Engineering Change Order (ECO). The ECO process ensures that all stakeholders are notified and that the BOM is updated in a controlled manner, preventing outdated versions from being used in production.

- Assign Clear Ownership: Every BOM should have a designated owner or team (typically in the engineering department) responsible for its accuracy and maintenance. This clear accountability prevents discrepancies and ensures someone is responsible for updates.

- Standardize Naming and Numbering Conventions: A consistent and logical part numbering system is essential. This prevents duplication reduces confusion and makes it easier to manage and search for parts within a large database.

- Regular Audits and Validation: Periodically audit the BOM against physical product builds and design documents to catch any errors or discrepancies. Any changes in suppliers or components must be immediately reflected in the BOM.

What are the most common challenges companies face when managing their BOMs?

Even with best practices, organizations face challenges:

- Data Inaccuracy: Simple typos, incorrect part numbers or wrong quantities can cause major disruptions.

- Poor Change Control: Failure to properly manage ECOs can lead to the wrong version of a product being built.

- Managing Variants: For companies with configurable products managing thousands of potential BOM variations can be incredibly complex.

- Supplier & Component Lifecycle: Components can become obsolete or "end-of-life." The BOM must be actively managed to identify and replace these parts before they disrupt production.

What is the future role of the Bill of Materials?

The BOM is evolving alongside manufacturing technology. In the era of Industry 4.0, the BOM is becoming more dynamic. It is a key element in the creation of a Digital Twin; a virtual replica of a physical product. This digital model fed by a live BOM can be used for simulations, predictive maintenance and operational analysis.

Furthermore, sustainability is adding new layers to the BOM. Companies are beginning to track additional data for each component, such as its carbon footprint, material origin for ethical sourcing compliance (e.g. conflict minerals) and recyclability.

How can Testcoo help manufacturers to ensure their Bill of Materials (BOM)?

The Bill of Materials (BOM) is a dynamic and indispensable asset at the core of every manufacturing enterprise. It is much more than a static list; it serves as a collaborative bridge that connects design, procurement, production and sales. A precise and well-managed BOM enables organizations to enhance efficiency, control costs and ensure consistent product quality creating a strong competitive advantage in today’s fast-paced global market.

As manufacturing processes and global supply chains grow increasingly complex, the strategic value of the BOM continues to rise. Partnering with professional third-party inspection and quality assurance experts like Testcoo helps ensure that every component, process and supplier aligns with your quality standards. From pre-production checks to final inspections, Testcoo provides tailored solutions that strengthen your supply chain, minimize risk and support long-term manufacturing excellence.

Want to ensure your product matches every BOM detail?

Partner with Testcoo for reliable inspections and supplier audits

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index