How to Conduct Third-Party Quality Control Inspections for Electric Scooters

Buy electric scooters from China? China has projected itself not only as the largest consumer of electric scooters but also a leading exporter and producer across the globe. In this article, we can discover the difference types of electric scooter inspection, the process of electric scooters inspection, and checklists of conducting electric scooters.

Besides, the e-scooter industry presents manufacturers and importers with the challenge of navigating complex and constantly evolving regulations. To guarantee quality, safety, and compliance, manufacturers and importers are increasingly turning to third-party quality partners-Testcoo, we can assist in navigating the intricate landscape of market regulations and ensure the products’ quality and safety.

Quality Inspections for Electric Scooters

As the popularity of e-scooter continues to rise, ensuring their quality and compliance with industry standards becomes crucial. To guarantee the highest level of quality control, companies often employ reputable inspection agencies such as Testcoo.

There are, in total, 5 types of inspection in quality control:

Initial Production Check (IPC)

Also called pre-production inspection, it takes place at the early stage of the production process, the inspectors will check the construction of the product against the approved sample and specifications (technical file, bill of materials etc.), as well as quantity, quality and other attributes of the materials, to make sure that a factory has properly understood your expectations associated with an order, and is well prepared for the manufacturing.

During Production Check (DUPRO)

This takes place when 20% to 50% of merchandise has been produced. The during production inspection checks quality of finished products, and provides an estimation of the level of quality. There is also Inline Inspection that offers corrective action plans to improve quality of the remaining production against defects identified.

Final random inspection is one common way to identify any discrepancy between production and specifications. It is conducted just before an order is dispatched. Inspectors inspect the quality, regulatory compliance, measurements and packaging of an order when the production is completed for 80% or move.

You need assurances that the number and nature of pieces shipped 100% conform with your shipment documents. Testcoo will check the way goods are staked in the container and seal it after loading.

100% inspection also called full inspection, checks the products piece by piece. 100% products are conformed to meet your requirement through repair of defective products.

How TESTCOO Conducts Final Random Inspection for Electric Scooter in China?

Find out how your inspector performs an onsite quality control inspection for electric scooters in China.

How to Conduct Third-Party Quality Control Inspections for Electric Scooters

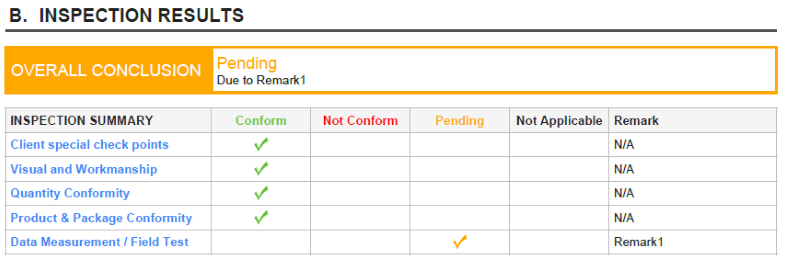

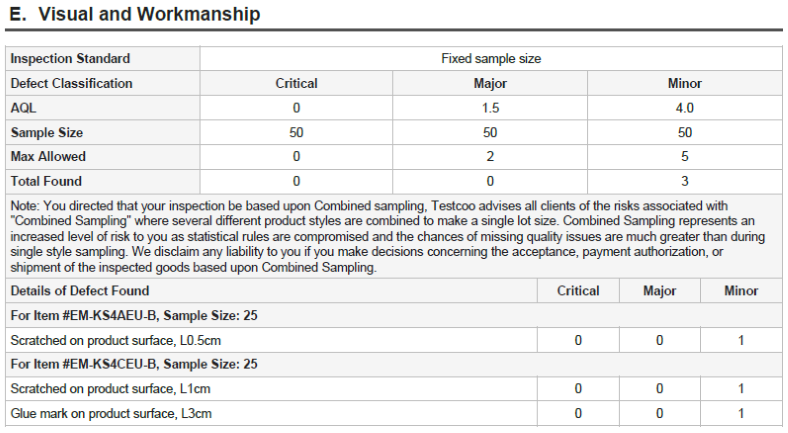

Visual and Workmanship

If no specific requirement from applicant, the inspector will visually inspect the exterior and interior parts of the electric scooter using inspection sampling plan, General Inspection Level II, AQL 1.5. 4.0. They’ll check for the following aspects, including:

- -Scratch marks, dirt marks, glue mark, abrasion

- -Defective parts

- -Identify any visible defects, such as rust or metallic luster, substandard surface coating, or oil stains.

- -Verification that the structure assembly aligns with the provided drawings.

- -Other

*All our reports come with high quality pictures of the detected issues

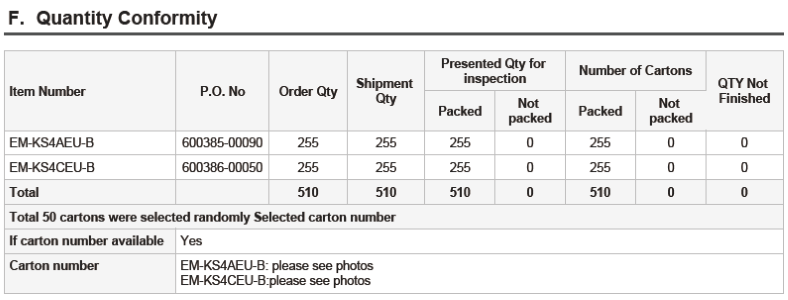

Quantity Conformity

Discrepancies in batch quantities can cause confusion, delays, and inventory tracking issues. Our inspection team conducts a thorough count and cross-checks of electric scooters ready to be delivered against purchase order documentation.

They compare the shipment’s quantity to the specified order quantity, ensuring precise alignment between the two. This meticulous process guarantees accurate documentation and facilitates smooth inventory management.

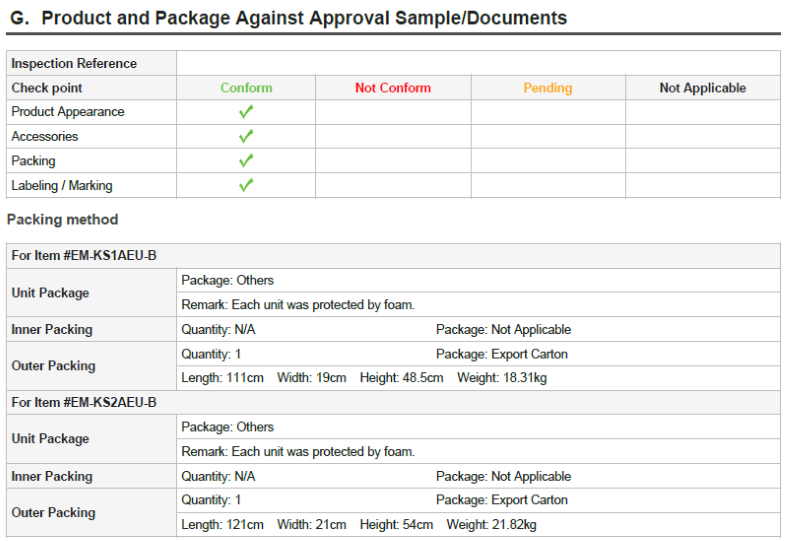

Product and Packaging Conformity

The product and packaging conformity service in Testcoo final random inspections for electric scooters includes an evaluation of the labeling and packaging aspects of the products. Reviewing the presence and accuracy of the Purchase Order, Product Specification, and User Manual.

These documents provide essential information about the product, its specifications, usage instructions, and any other specific requirements requested by the client. Besides Testcoo will review other specific questions around the documentation provided by the client. It includes the next items:

- -Product Appearance Verification

- -Accessories Verification

- -Packing Verification

- -Labling/ Marking Compliance

Data Measurement and Field Test Checklist

The inspection service provided by Testcoo for electric scooters in the final random inspection report includes a comprehensive range of tests and checks to ensure the quality and performance of the products. Here are the specific tests and checks conducted:

1. Transportation Drop Test

No critical & Major issue found on package & product after (10 times) drop test according to the standard of ISTA 1A.

2. Product Size, Power cord length, Weight Measurement

According to product spec or approved sample. Apply +/- 3% if no detail tolerance issued or requirement from client.

3. Barcode Scan Check

The barcode of the e-scooter must be scannable and with the correct number.

4. Assembly, Installation Check

The assembly of the e-scooter is inspected to verify that all components are assembled smoothly according to the instruction manual or guideline, and no issue found.

5. Full Function Check

All captioned function of the e-scooter is well conducted as intended in instruction manual, such as installation, adjusting, switch/knob action check, setting, display, modes setting, remote control function, actual using function etc. all of function should be complied with claims.

6. Coating Adhesive Tape Test

A coating adhesive tape test of the e-scooter is measured to ensure no more than 10% area of all painting, foil stamping, UV coating, printing peel off required.

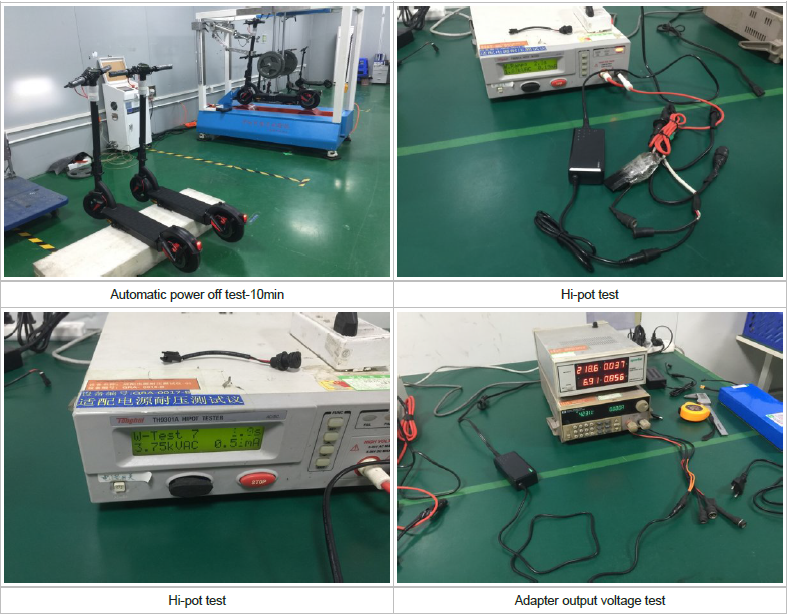

7. High Voltage Test

This test checks the electrical insulation of the e-scooter by applying a high voltage to detect any potential electrical issues or safety hazards.

The testing voltage required: For the USA/Canada markets: class I: 800Vac class II: 1500Vac For European markets: class I: 1500Vac class II: 2500Vac for AC adaptor: for USA/Canada markets: 1200Vac for Europe markets: class I: 2100Vac; class II: 4200Vac no insulation breakdown.

8. Power on Check

The good condition samples should be operating at full load (preferable) at least 4 hours at rated voltage or time reference the user instruction if less than 4 hours. after testing the sample e-scooter should pass the hi voltage check, function check, earth continuity check etc., and no defect found.

9. Power Consumption Check or Input Power, Current Check

The e-scooter power consumption, input power, current are checked to be comply with product spec and safety standard.

10. Internal Workmanship and Critical Component Check

Check internal construction completement and main components of e-scooter according with CDF(Constructional Data Form) or CCL (critical components list).

11. Rubbing Test for Rating Label and Adhesive Test for Printing, Marking and Logo

This test is conducted to make sure that the rating label, printing, marking, and logo don’t rub off.

12. Waterproof Testing

The electric scooter undergoes testing to assess its resistance to water and verify its waterproof capabilities, this includes some specific tests like the water resistance test (IP67) and more

13. Charging, Discharging Check

Charging and discharging of e-scooter are inspected to ensure it meets requirement.

14. Auto-off Time Check

Auto-off time of e-scooter is checked to ensure it operates with the requirement.

15. Abusing Test and Actual Performance Test

16. Basic Function Check

The basic function check of the e-scooter is evaluated, including aspects such as acceleration, braking, stability, and handling.

17. Max Rang Check

18. Max Speed Check

The speed of the motor is assessed to ensure it operates within the max speeds.

19. Loading Test

This check examines how the e-scooter performs when subjected to a specified load or weight capacity to ensure it functions properly under normal operating conditions.

20. Climbing Angle Test

21. Handle Grips Force Pull Test

Handle grips force pull test of e-scooter is assessed to verify handles grips are not easily being pulled out or come apart.

22. Handle Pull Test

23. Charger Output Voltage

Charger output voltage is inspected to verify that reaches the e-scooter voltage.

By conducting these tests and checks, Testcoo ensures that the e-scooters meet the necessary quality standards, perform reliably, and comply with safety requirements, providing confidence to both manufacturers and consumers.

Conclusion: E-Scooter Quality Inspections Agency in China

TESTCOO is a qualified e-scooter quality control inspection company in China. Contact us today to learn more about our comprehensive inspection services and how we can help you ensure the quality and compliance of your e-scooter products.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index