AQL Table | How to Read It

When you are planning to arrange quality control of the products you import from Asia, you probably wonder: Is it necessary to check 100% of the products to know overall quality of the batch?And how can you determine whether products Passed or Failed the inspection?

The AQL table is widely used to assess quality of the batch without checking the full quantity of products. It is the main tool of the inspectors to use during product inspection, as well as the main metric for importers to decide whether to accept a certain batch of products.

It can be considered as the maximum limit of defects for a certain number of products in the order.

Your Inspection Case Briefly Explained

Let’s imagine you have a batch of blenders with a total quantity of 7000 pcs that needs to be inspected before shipment. According to our default level of AQL (Level II, Maj. 2.5 Min. 4.), the sample size for inspection of your order should be 200 pcs.

If, during inspection, the inspector finds 11 or more Major defects, it is recommended not to accept the entire batch of blenders. However, if the batch with these AQL settings passes the inspection, there will be a 95% probability that less than 5% of the products will be defective.

Now in More Detail

As your first step, select a General Inspection Level for your order. It determines the amount of products to be checked during inspection (sample size) and is usually based on your budget for the inspection.

-The most commonly used inspection level is General Inspection Level II; the majority of inspections tend to follow this level.

-General Inspection I calls for a smaller sample size than General Level II (reducing the time needed to perform the inspection, but increasing the risk that defects may be missed).

-General Inspection III calls for a larger sample size than General Level II (increasing the time needed to perform the inspection, and decreasing the risk of missing defects in the shipment).

Choosing Sample Size for Your Inspection

Back to your blenders. You are purchasing a batch of 7,000 pcs and based on General Inspection Level 2, the recommended sample size for your inspection will be 200 pcs. If you chose General Inspection Level 1, it would be 125 pcs, and if you chose General Inspection Level 3, it would be 315 pcs.

How we came to it

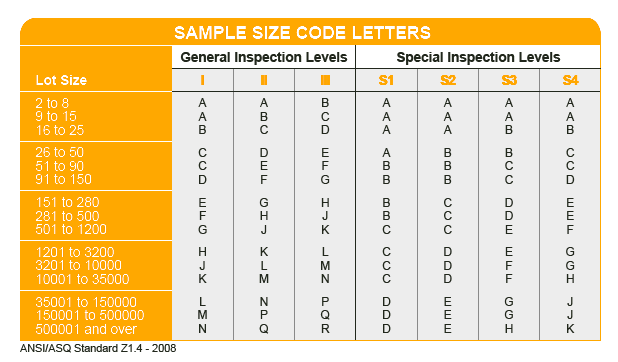

To understand the sample size for inspection of your order and acceptance level, look at the AQL Table below. Find the batch size, follow the intersection of batch size and chosen general inspection level to find the letter code of your sample size.

For an order of 7000 pieces, the letter code in this case will be “L”. In the second AQL Table, you can see that the letter "L" indicates 200 pieces, which will be a sample size for your inspection.

Table AQL (1), sample size identification

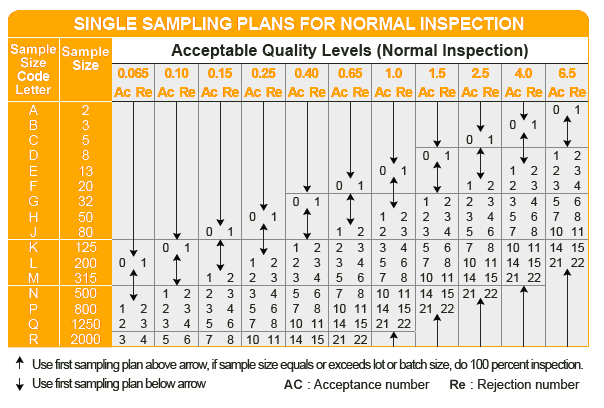

Table AQL (2), determination of acceptance limit

Your Case | Choosing Acceptance Limit for Your Inspection

After knowing the sample size taken from the batch during inspection, the next step is choosing the acceptable quality limit of your products.

TESTCOO’s default limit is Cri. 0 | Maj. 2.5 | Min. 4, which means that the limit of Critical defects is 0, Major defects are 2.5, and Minor defects are 4. These limits indicate the maximum number of product defects in the sample size for acceptance of the order.

You can establish your own acceptance limits based on your acceptable quality. For high-value products sometimes Cri. 0 | Maj. 1.5 | Min. 4, is used, or even Maj. 1.0 | Min. 2.5.

To determine the number of acceptable defects in production, find within the tables the sample size and then the quality limit - the acceptable (Ac) and rejected (Re) number of defects will be indicated at the intersection.

Taking our example with blenders, for a sample size of 200 blenders, the acceptable number of Major defects is 10 pcs (limit 2.5), and Minor defects - 14 pcs (limit 4). If more defects are found for at least one indicator, the result of the AQL check will be "FAILED" in the inspection. In this case, it is recommended to not accept the order for shipment, and negotiate with your supplier on how to proceed.

What to Do with Defective Samples

If a batch of goods has not passed the AQL inspection, you can still accept it if you want to, even if the inspection report indicates that your products “Failed”.

You can ask your manufacturer or supplier representative to sort, repair, or replace the defective products. It is also possible to purchase a defective product at a discount, referring to unsatisfactory quality or defects.

To check whether quality meets your requirements, we are always glad to offer help. TESTCOO offers a variety of Quality Control services, such as Product Inspection, Factory Audit, and Laboratory Testing in Asia.

Feel free to visit our website www.testcoo.com to get to know more about our company and services, and should you have any questions, please feel free connect with us via service@testcoo.com.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index