What is Quality Inspection? A Complete Guide

What is quality inspection? According to the ISO 2859 standard, quality inspection involves activities such as testing, gauging, examining, or measuring one or more product characteristics. Quality inspection can help companies determine if their products comply with marketing and quality standards.

Contents

What is Quality Inspection?Quality Inspection vs. Quality Control

The Importance of Quality Inspection

What are the 4 Types of Quality Inspection?

4 Reasons Why Global Buyers Choose TESTCOO to Conduct Quality Inspection

Inspections vs Audits vs Lab Tests: What’s the Difference?

TESTCOO Enhances your Company’s Quality Management

FAQs

What is Quality Inspection?

Quality inspection is a process of ensuring that products or services meet specified requirements and standards before they are delivered to customers or released into the market. It involves evaluating, verifying and testing items for defects, deviations, or non-conformities that may affect their performance, safety, reliability, and usability.

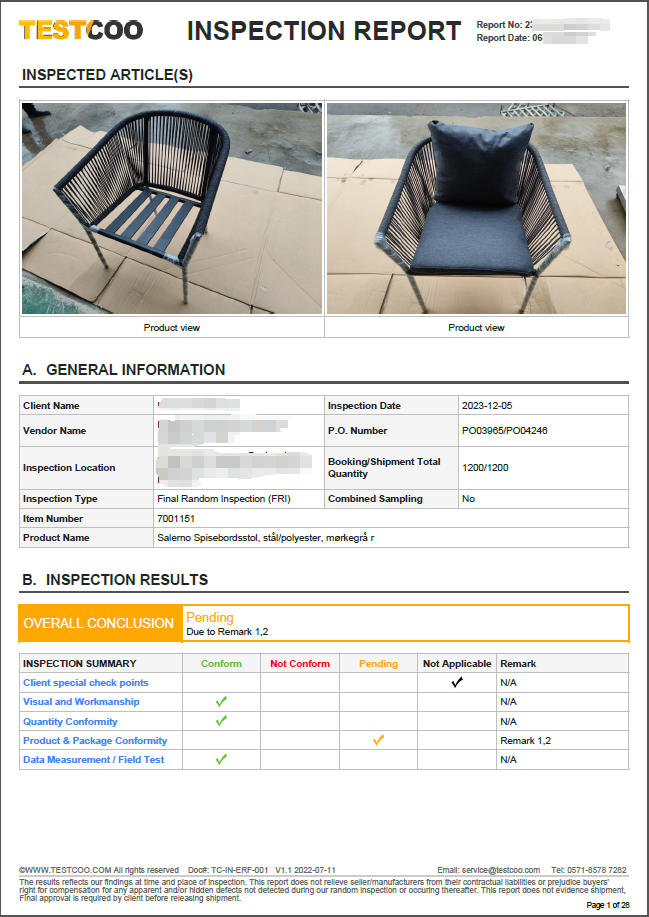

Quality inspectors usually carry out on the basis of a checklist developed by third-party inspection companies or buyers. The results of the inspection is then compiled into a report, that indicate whether or not the product conform to the specifications.

An effective quality management solution can enhance product quality, streamline quality processes and workflows reduces the time and resources, and help ensure compliance with industry regulations, standards, and best practices, reducing the risk of non-compliance penalties and legal issues.

Quality Inspection vs Quality Control

Quality inspection is a process of examining and evaluating products, components, or materials to ensure they meet specified requirements and standards. It doesn’t have a direct influence on the production process. The products are checked by inspectors so as to ensure they are fit for mass production and shipment to customers. The findings from the inspection are consolidated into an inspection report, which provides an overview of whether the product meets the specified requirements and standards.

Quality control is defined by the ISO 9000: “A part of quality management focused on fulfilling quality requirements.” Quality control refers to the process of ensuring that products, services, or processes meet established quality standards and specifications.

The main objective of quality control is to ensure that the final product or service meets customer expectations in terms of quality, performance, and reliability. This not only helps to build customer loyalty but also helps businesses to enhance their brand reputation and increase market share.

Companies use a set of quality control activities that involves monitoring and controlling the production process to assess whether or not the product is fit for its purpose and defined standards. These activities often include quality inspections.

The Importance of Quality Inspection

It is virtual for buyers to maintain the product quality, as it directly impacts customer satisfaction and brand reputation.

Quality inspection determines and verifies the quality of the products to ensure that delivered products are the same as expected, monitors and supervises the manufacturing process to avoid shipping delay.

Quality inspection controls quality, reduces manufacturing costs and rejection losses, and assigns causes for the production of a defective product. Quality inspection during the product manufacturing process ensures standardization and uniformity for controlling the product quality by comparing it with the standards and specifications.

Quality inspection is also conducted to reveal the product defects, style, functions, workmanship, and packages and reported to the buyers for deciding whether pass or reject product release.

What are the 4 Types of Quality Inspection?

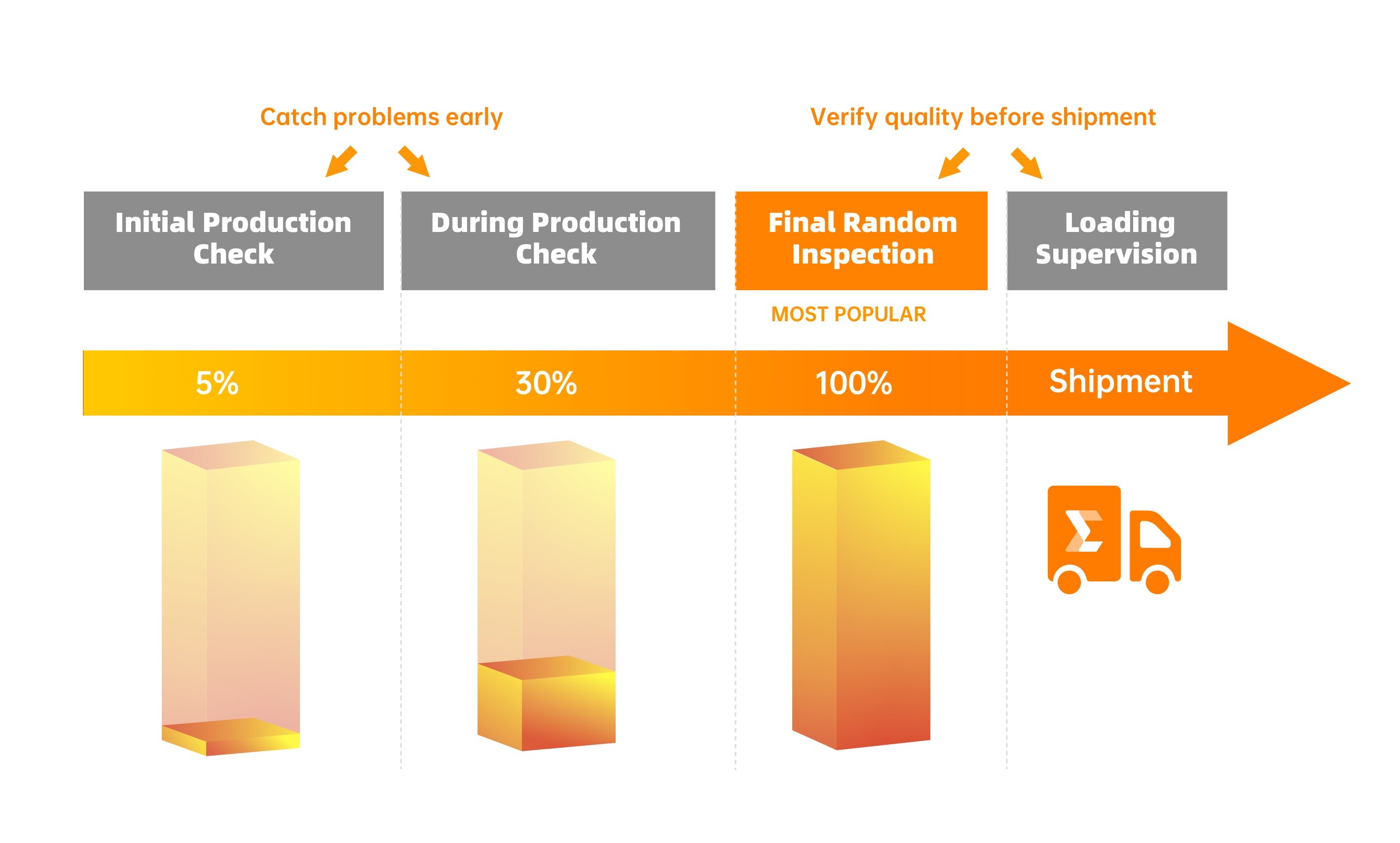

Quality inspection checks for quality and identifies ways to minimize manufacturing costs, reduce scrap losses and mitigate causes of defective work. There are mainly 4 types of inspection in quality control assess the quality of products, ensuring consistent production processes and effective control systems:

Initial Production Check (IPC)

During Production Check (DUPRO)

These four types of inspection is carried out at a different stage of product manufacturing process. Based on your specific requirements and industry, you may find that one or all of these four inspection types are of the essence.

1. Initial Production Check (IPC)

The Initial Production Check (IPC) takes place at the beginning of the manufacturing process to assess the production readiness of a factory and ensure that initial production runs meet the buyer's specifications and quality standards. It is the first step in ensuring that your supplier will consistently manufacture good quality products.

By conducting an IPC, buyers can proactively address any issues early in the production process, minimizing the risk of defects, delays, and quality problems in the final product.

2. During Production Check (DUPRO)

During Production Check (DUPRO) is conducted when 30%-50% of goods are completed so that to ensure consistent quality in the manufacturing process. It allows you to identify any issues or defects early on and enables manufacturers to take corrective actions before large quantities of defective products are produced.

DUPRO is especially valuable for products that are in continuous production and have stringent quality requirements. Conducting DUPRO can minimize the risk of producing substandard goods and ensure that the final products meet customer expectations, thereby reducing delays and rework.

3. Final Random Inspection (FRI)

Final Random Inspection (FRI, known as pre-shipment inspection) is the most popular and commonly used quality inspection method. Final inspection takes place when your production is 100% completed and at least 80% of goods packed and seated in shipping cartons for verification of your purchase specifications.

Checklists of the final random inspection:

- Inspection conditions: product status, carton stacking, shipment quantity, etc.

- Packaging and assortment: carton packing, product packing, and assortments such as -color/styles/sizes.

- Shipping marks: printings, warming and symbols.

- Labeling: labels, markings, etc

- Product conformity: Style, materials, colors.

- Workmanship: appearance, basic functions.

- On-site test: barcode verification, measurements, weight, functionality, etc.

Final inspection is an important step in the quality control process that ensures the production complies with the specifications of the buyer.

Read more about a pre-shipment inspection: 9 Important Steps in a Pre-Shipment Inspection Procedure

4. Loading Supervision (LS)

Loading Supervision (LS) is the final but crucial step in the quality control process that is properly preparing batches for shipping to destination markets.

Container loading inspections is usually performed at the factory, forwarders port to verify count to ensure your products are loaded correctly. Inspectors will supervise throughout the whole process and ensure your products are handled professionally to guarantee their safe arrival to their final destination. Also, this inspection confirms products are consistent with the packing list of the client, ensures the correct amount of different styles, sizes, quantities, and verifies all the product information, and packaging compliance.

Product inspections play a crucial role in reducing product returns due to defects or poor quality, which can significantly impact your profit. By choosing the right inspection service, you can effectively reduce return rates, maintain profitability, and ensure customer satisfaction.

TESTCOO INSPECTION SERVICE can help oversee buyers to identify the quality of products at the source with product inspections and sample checks to avoid the risk of getting non-conformed production at your destination.

Request a quote4 Reasons Why Global Buyers Choose TESTCOO to Conduct Quality Inspection

- A dedicated person will be assigned to follow up your inspection request from start to end to ensure a smooth communication.

- Unique online platform with individual access empowers to book inspection and review report at anytime and anywhere.

- Highly competitive and all-inclusive rate as per country without charging additional travel costs.

- With world-class dashboards and reports, it was easy to have effective supplier management.

Currently TESTCOO provide QC service to key players in international trade community including retailers, brands and importers: Inditex (Spain), Mayoral (Spain), Li & Fung (China), Hunter (England), Sketchers(USA), Tommy Hilfiger(USA), Calvin Klein(USA) , IKKS (USA), Kidiliz (France), BUT(France), Cencosud (Chile), Kesko(Finland), SWAROVSKI, The Vermont Teddy Bear, Furniture And Choice, Jetsonbike, Siemens, BestBuy(USA), Legrand(France), Ourolux (Brazil), Kian (Brazil).

If you’d like to learn more about how these companies cooperate with TESTCOO, contact us:

Inspections vs Audits vs Lab Tests: What’s the Difference?

Inspections: Inspections involve a thorough examination of a process, system, product, or facility to ensure compliance with specific criteria or standards. The primary aim is to identify defects, deviations, or non-compliance that can impact the quality, safety, or functionality of the item being inspected.

Product inspections typically take place at the factory where inspectors check the products for conformity to requirements. The frequency of inspections will vary depending on the industry, product, or process being inspected.

Audits: Factory audits are the assessment for production capability and performance of a factory against proven quality principles. Every production site needs reliable manufacturing and quality control systems to ensure customers are satisfied with their products.

Audits are performed to ensure that a company’s internal processes, controls, and systems are compliant with established standards, industry regulations, or company policies. They are often used for quality management, environmental performance, and documentation of health and safety.

Lab tests: Lab tests are another way to help enter the destination markets through physical and chemical testing for your products. Product testing typically occurs in a specialized lab by using advanced equipment setting to verify product safety, compliance, or performance. You might test your products to check for harmful chemicals, comply with regulations, or simulate repeated use.

TESTCOO Enhances your Company’s Quality Management

TESTCOO is the leading 3rd party quality control inspection service agency in China, which is fully accredited by ISO9001, ISO 27001, CNAS17020 and AQSIQ. We offer product inspection service(IPC, DUPRO and FRI), Loading Supervision, Sample Picking, Supplier Audit and QIP (Quality Improvement Project Service).

Our QC teams cover most regions in China as well as many other Asian countries (Vietnam, Thailand, Cambodia, Philippines, Malaysia, Indonesia, Bangladesh, India, Pakistan and Myanmar) and Turkey. All our inspectors or auditors have university degree with at least 5-year QC working experience in specific fields (Softgoods, hardgoods or E&E products). And we have a professional technical team with strong expertise in quality assurance and a CRM team to offer timely service.

DOWN A QUALITY INSPECTION SAMPLE REPORT

TESTCOO detailed inspection reports and continuous support help you improve processes, take corrective actions, and maintain quality.

FAQs

What does a Quality Control Inspector do?

Quality Control Inspectors visit the factory, check the product and factory according to the checklist and record the results of their inspections and prepare inspection reports. When they identify defects, inspectors inform supervisors to let them analyze and rectify the production problems.

What are the benefits of Quality Inspections?

Quality Inspections at various stages of the production process, from Initial Production Check to final inspection, can help you monitor product quality to ensure requirements are being fulfilled and to support timely delivery.

Ensuring product quality and safety: quality inspection can guarantee that the products being manufactured meet the required quality standards. Inspections help identify potential defects, irregularities, or deviations from specifications that may compromise the product’s quality or safety. Mitigating Risks and Ensuring Compliance:

Building trust and confidence: quality inspections serve as a means to establish trust and confidence among buyers, suppliers, and consumers. Buyers rely on factory inspections to verify suppliers to ensure they adhere to quality standards, meet delivery timelines, and maintain consistent product quality.

Improving Supply Chain Management: quality inspections contribute to effective supply chain management. By conducting inspections promote transparency in the supply chain, allowing buyers to make informed decisions and choose suppliers who consistently meet quality and compliance requirements. Effective supply chain management, supported by inspections, ensures smoother operations, reduces costs, and enhances overall productivity.

What are the Quality Control Inspection Standards?

Standards and certifications are the guiding principles and benchmarks that shape the practices and processes of quality control.

ISO 2859 – Sampling Procedures for Inspection by Attributes

ISO 2859 helps in determining the sample size, inspection levels, and acceptable quality levels (AQLs) – crucial factors in deciding whether a batch passes or fails the inspection.

ANSI/ASQ Z1.4 – Sampling Procedures and Tables for Inspection

Just like ISO 2859, the ANSI/ASQ Z1.4 standard is widely used for determining sample sizes and setting quality levels.

ISO 9000 Series – Quality Management Principles

ISO 9000 provides a set of standards that help organizations ensure they meet customer and other stakeholder needs within statutory and regulatory requirements related to a product or service.

AQL (Acceptable Quality Limit)

Inspections follow the internationally recognized ANSI/ASQC Z1.4 (ISO 2859-1) statistical sampling procedure to specify a percentage of a batch of products which must be inspected to represent the overall quality of the entire batch, commonly referred to as the Acceptable Quality Limit (AQL).

Read more about AQL and learn to read AQL table: AQL

How to prepare for a quality inspection effectively?

Choose a third-party inspection company: employing a reputable 3rd party inspection agency with expertise in your industry. Ensure that the chosen inspection agency is qualified and experienced in conducting production inspections.

Develop a checklist: whether someone on your team conducts quality inspections or you employ a third-party QC company (Like TESTCOO Inspection agency) to do so, it is essential to have an effective quality control inspection checklist. A well-thought-out checklist gives you or the inspection service provider clear criteria to follow when checking your products.

Communicate with the Factory: communicate the purpose, scope, and expected outcomes of the inspection. Provide any necessary documentation or information that the factory may need to prepare.

Follow up: once an inspection has been completed, there may be corrective actions and other essential processes for appropriate follow-up.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index