On-site Carton Drop Check, Referred to the International Safe Transit Association (ISTA)

This method is reference to The International Safe Transit Association (ISTA) Pre-shipment Test Procedures 1996.

1. On-site Carton Drop Check

Usually, we use the Ten Time Carton Drop method if the customer has no special requirements.

2. Ten Time Carton Drop

1. Checking Method:

1) Inspect the products inside carton and make sure they are “good” samples.

2) Repack them as per original packing method.

3) Perform carton drop test according to the WI for which Drop test method will be adopted.

3. Drop test height is determined by carton weight

Packaged - Product Weight | Drop Height | ||||

Equal to or Greater than | But Less than | Free Fall | |||

lb | kg | lb | kg | in. | cm |

0 | 0 | 21 | 9.5 | 30 | 76.2 |

21 | 9.5 | 41 | 18.6 | 24 | 61.0 |

41 | 18.6 | 61 | 27.7 | 18 | 45.7 |

61 | 27.7 | 100 | 45.3 | 12 | 30.5 |

100 | 45.3 | 150 | 68 | 8 | 20.3 |

For example, if the weight of a carton is 25kg, greater than 18.6kg but less than 27.7kg, the drop test height of this carton is 18 inches.

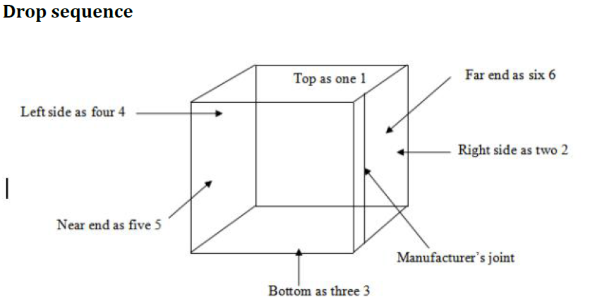

4. Drop or impact the packaged product according to the following sequence

Drop or impact the packaged product according to the following sequence:

Ø One corner-the joins of edges with staples or gum are considered weaker than the other edges.

1. Test the most fragile face-3 corner, if not known, test the 2-3-5 corner.

Ø Three edges-3 different length (long, width and height) radiating from the dropped corner.

1. The shortest edge radiating from the corner tested.

2. The next longest edge from the corner tested.

3. The longest edge radiating from the corner tested.

Ø Six face-All flat surfaces.

1. Flat on one of the smallest face.

2. Flat on the opposite small face.

3. Flat on one of the medium face.

4. Flat on the opposite medium face.

5. Flat on one of the largest face.

6. Flat on the opposite large face.

Note: Should select a concrete floor to perform the Drop Check.

5. After drop test, inspector shall open the carton and follow the steps

1) Check whether packaging is damaged or

2) Inspect the products again to check any defectives, which shall include the Product appearance and functions.

3) Selected the samples from the critical area (Most in the dropped corner).

4) Whole carton or minimum 24 units will be inspected.

6. Kindly tips for drop test

-In any case, drop check cannot be performed is due to some other reasons (for instance: lack of manpower, complicated packaging method…etc.), we must call supervisor for confirmation, then we must state the reasons on the inspection report for applicant reference.

-It is very important to have well planning on performing the In case the goods are packed with blister card, clam shell blister or tightened with strings, we shall inspect some units up to a certain quantity first (quantity for one carton) and ask the factory to re-pack them immediately for our testing instead of arrange the test at the end of the inspection.

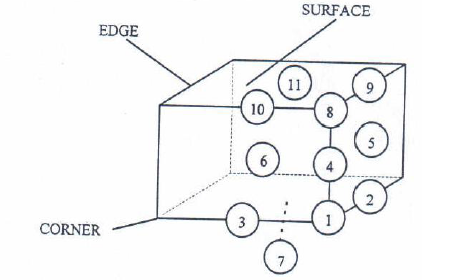

7. Eleven Time Carton Drop

Some customers may choose eleven time carton drop. For this drop:

1) Standard based on DIN 55 440/ PZT (Deutsche Bundespost )

2) Drop test height of eleven time carton drop is similar to that of ten time carton drop.

3) Drop the carton with the following sequence (11times)

-1 (the most fragile face-3 corner. if not known, test the corner which in the joint of carton), 8 on the corner

-2, 3, 4, 9, 10 on the edge

-5, 6, 7, 11 flat on surface

Notes: The surface on which the drops are made must be solid steel or concrete. Wooden floor is not acceptable as a drop surface under any circumstances.

4) Checking condition and Acceptance Criteria:

-The items inside the sample carton should be inspected with “Good” result;

-Repacked the unit as per the shipping configuration;

-Perform the carton dropping;

-Inspect the packaging to see whether it is damaged;

-Up to 36 pieces of packed items would be inspected if the pack size is greater than 36;

-Item would be selected from the dropped corner and the projected edges of the carton;

-Inspect the item inside by visual check, functional check and safety checks.

8. Drop test is an important part of your shipment inspection

As most of the products supply chains are located in countries far away from the brand buyers and the products cartons should be transferred for a long distance, it is essential to conduct a carton drop test before shipment to ensure the products are fully protected and can bear collision during transportation. Also, every consumer doesn’t want to receive a product with poor package. Products like home appliances, beauty makeup products, children toys, textiles and garments, and ceramics are highly suggested processing carton drop test before shipment.

----------------------------

TESTCOO is a leading third-party inspection company in China. Testcoo performs over 100,000 product inspections, factory audits, and lab tests annually and is trusted by 5,000+ retailers, brands, and suppliers worldwide.

Testcoo can help you complete a full QC inspection in China more efficiently and effectively. It offers the following QC inspection services to assess and satisfy its global customers:

- Initial Production Check (IPC)

- During Production Check (DUPRO)

- Final Random Inspection (FRI)

- Loading Supervision (LS)

- 100% Inspection

- Sample Picking Service (SPS)

- Supplier Audit

If you need some practical experience in quality control, you can definitely discuss with us. As a Chinese inspection company, we can provide product inspection, factory audit, lab testing, and Amazon FBA inspection. If you need it, you can get the most suitable quotation from us. Check a sample report.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index