Holiday Rush, Zero Defects: Why Winter Is the Most Critical Season for Product Inspections

The holiday season is the most profitable and most risky time of the year for global manufacturing and retail supply chains. From Black Friday and Christmas to New Year sales and winter clearances, brands face an unprecedented surge in demand. Production lines run longer hours, shipment deadlines tighten, seasonal workers are onboarded quickly and factories are pushed to their operational limits.

In this high-pressure environment, product inspections become the difference between a successful holiday season and costly post-holiday damage control.

Winter is not just another quarter in the manufacturing calendar. It is a convergence of peak production pressure, environmental challenges and logistical constraints. Defects that might go unnoticed during regular seasons often spike during winter not because factories intend to compromise on quality, but because systems are under stress.

This is why the winter and holiday period is the most critical season for inspections and why brands that invest in quality control during this time consistently outperform those that don’t.

The Holiday Production Surge: Why Quality Is Most Vulnerable in Winter

As the holiday season approaches, manufacturing enters its most intense phase of the year. Order volumes spike, production timelines shrink and factories are pushed to operate at maximum capacity to meet festive demand. To keep up, many manufacturers extend working hours, onboard temporary labor and fast-track production schedules. While these measures help meet delivery deadlines, they also create the perfect conditions for quality lapses. Reduced buffer time, workforce fatigue and compressed quality checks make winter the season when defects are most likely to occur—turning quality control into a critical safeguard rather than an optional step.

Peak Demand Compresses Timelines

Holiday orders are rarely spread evenly. Brands often finalize forecasts late, marketing campaigns accelerate demand and factories are asked to produce more faster.

This leads to:

- Shortened production cycles

- Reduced buffer time for quality corrections

- Overlapping production runs

- Fewer opportunities for internal audits

When timelines shrink, quality risks grow.

Seasonal Workforce Challenges

To meet holiday demand, many factories:

- Hire temporary or contract workers

- Reassign workers to unfamiliar product lines

- Increase overtime shifts

While this is operationally necessary, it introduces risks such as:

- Inconsistent workmanship

- Improper handling of materials

- Missed SOP steps

- Higher fatigue-related errors

Inspections act as a neutral checkpoint to ensure consistency when workforce experience varies.

Quality Check in Manufacturing: A Step-by-Step Guide for Global Buyers

How Winter Conditions Directly Impact Product Quality

Winter affects manufacturing in ways that are often underestimated. As temperatures drop and holiday demand rises, factories face tighter timelines, environmental challenges and increased operational pressure. Cold weather affects how materials behave, how adhesives cure and how products withstand storage and transit. At the same time, seasonal labor and rushed production increase the risk of workmanship defects. Together, these factors make winter one of the most vulnerable periods for product quality. Understanding how winter conditions impact manufacturing is essential for preventing defects, avoiding shipment rejections and ensuring consistent quality during peak holiday seasons.

Cold Temperatures and Material Behavior

Low temperatures can significantly affect:

- Adhesive curing

- Glue viscosity

- Rubber flexibility

- Plastic brittleness

- Fabric shrinkage

Common winter-related defects include:

- Sole separation in footwear

- Weak bonding in bags and accessories

- Cracking in plastic components

- Fabric stiffness or dimensional instability

Without inspection, these defects often surface after the product reaches the consumer when it is too late.

Humidity and Storage Issues

In winter, improper storage conditions can lead to:

- Mold or mildew formation

- Fabric odor issues

- Rust on metal components

- Condensation damage during packing

These issues are especially common when:

- Warehouses are poorly ventilated

- Heating systems are inconsistent

- Goods are packed immediately after production

Pre-shipment inspections play a crucial role in identifying such risks before goods leave the factory.

Down Garment Quality Control Inspections-Method and Checklist

Holiday Shipping Pressure: Zero Margin for Error

The holiday season leaves no room for mistakes in global shipping. As order volumes surge and delivery timelines shrink, even minor delays or quality lapses can lead to missed selling windows, rejected shipments and dissatisfied customers. Ports face congestion, logistics networks are stretched and weather-related disruptions become more frequent during winter months. In this high-pressure environment, manufacturers and brands operate with zero margin for error. Every shipment must be right the first time. This is why careful planning, robust packaging and timely pre-shipment inspections become critical during the holiday rush—ensuring products arrive on time, intact and ready for peak-season sales.

Missed Delivery Windows Are Costly

During the holiday season:

- Late shipments often mean canceled orders

- Retailers reject goods that miss seasonal windows

- Products lose relevance immediately after holidays

A defect discovered after shipment can result in:

- Air freight costs

- Heavy discounts

- Returns and refunds

- Reputational damage

Inspections ensure that shipments leave right the first time.

Increased Port and Logistics Congestion

Winter months often coincide with:

- Port congestion

- Customs delays

- Weather-related transport disruptions

With limited flexibility to re-ship or rework, quality must be assured before dispatch.

Read more: Container Loading Inspection for Safer Shipments

Defects That Spike During the Holiday Season

The holiday season places extraordinary pressure on manufacturing operations. As order volumes surge and deadlines tighten, factories often operate at maximum capacity with reduced margin for error. Seasonal hiring, extended shifts and compressed production timelines increase the likelihood of quality lapses. At the same time, winter conditions affect material behavior, storage environments and packaging integrity. Together, these factors create a perfect storm where certain defects appear more frequently than during regular production periods. Understanding which defects tend to spike during the holiday season allows buyers and quality teams to focus inspections on high-risk areas—preventing costly rejections, delays and post-holiday customer complaints. Based on industry inspection data, the following defects are more frequently observed during winter production:

Apparel & Textiles

- Incorrect measurements due to fabric contraction

- Skipped stitches and loose threads

- Shade variations in winter dye lots

- Poor finishing due to rushed packing

Footwear

- Sole adhesion failures

- Cracked uppers

- Glue marks visible in cold conditions

- Inconsistent sizing

Toys & Consumer Goods

- Sharp edges due to brittle plastics

- Loose components

- Packaging damage during cold storage

Electronics & Hard Goods

- Condensation-related corrosion

- Faulty soldering

- Packaging failures during transit

Each of these defects is preventable if inspections are timed and executed correctly.

Read more: Common Fabric Defects in Garment Manufacturing and How to Identify Them During Inspection

Why Winter Inspections Need a Different Strategy

Winter changes everything on the factory floor. As temperatures drop and holiday demand rises, manufacturing risks increase in ways that standard inspection approaches often fail to capture. Materials behave differently in cold conditions, production timelines compress and factories operate under intense pressure to meet seasonal deadlines. Relying on routine inspection methods during winter can leave critical defects unnoticed until products reach the market. This is why winter inspections require a different strategy—one that accounts for environmental factors, peak-season workforce challenges and tighter logistics windows. A season-specific inspection approach helps brands detect risks earlier, protect product quality and avoid costly holiday-season failures.

One Inspection Is Not Enough

During peak season, relying on a single final inspection is risky.

A winter inspection strategy should include:

- Initial production inspection (material readiness)

- During production inspection (process control)

- Final random inspection (shipment readiness)

This layered approach catches issues early when correction is still possible.

Winter-Specific Checkpoints

Effective winter inspections include additional focus on:

- Adhesive curing time

- Environmental controls

- Storage conditions

- Packaging integrity for cold transit

- Carton strength and drop resistance

Generic inspection checklists often miss these seasonal risks.

The Cost of Skipping Inspections During Holiday Rush

The holiday season is when manufacturing pressure peaks—and quality risks rise silently. Tight deadlines, increased order volumes, seasonal labor and accelerated shipping leave little room for error. In this rush, skipping or reducing product inspections may seem like a time-saving decision, but it often leads to far greater costs later. Defects that slip through during peak season can result in shipment rejections, customer complaints, returns, chargebacks and lasting brand damage. When delivery windows are unforgiving and consumer expectations are highest, inspections are not an optional step—they are a critical safeguard against costly holiday-season failures. Brands that reduce inspection frequency during peak season often do so to save time or cost. In reality, this decision usually backfires.

Hidden costs include:

- Customer complaints

- Retail chargebacks

- Brand damage on social media

- Emergency rework expenses

- Loss of repeat business

In contrast, inspections typically cost less than 1% of the order value, while failures can wipe out entire seasonal margins.

Shopping for Christmas trees? Get the best quality artificial Christmas trees.

Inspections as a Business Continuity Tool, Not Just Quality Control

Inspections are often seen as a final checkpoint to approve or reject goods, but in today’s volatile supply chains, their role goes far beyond quality control. Especially during peak seasons, inspections act as a business continuity tool—helping brands anticipate risks, maintain production stability and protect delivery commitments. By identifying issues early, inspections prevent last-minute disruptions, costly rework and shipment delays. They provide real-time visibility into factory performance, workforce consistency and process reliability, enabling informed decisions when timelines are tight. In an environment where a single failure can derail an entire season, inspections ensure continuity, confidence and control—not just compliance. Modern inspections are no longer about pass/fail results alone.

During the holiday season, inspections help brands:

- Predict risk trends

- Identify weak suppliers

- Improve production planning

- Reduce last-minute surprises

- Protect customer trust

Brands that treat inspections as a strategic tool, not a checkbox gain a competitive advantage.

Why Buyers Increase Inspections During Winter (Best Practices)

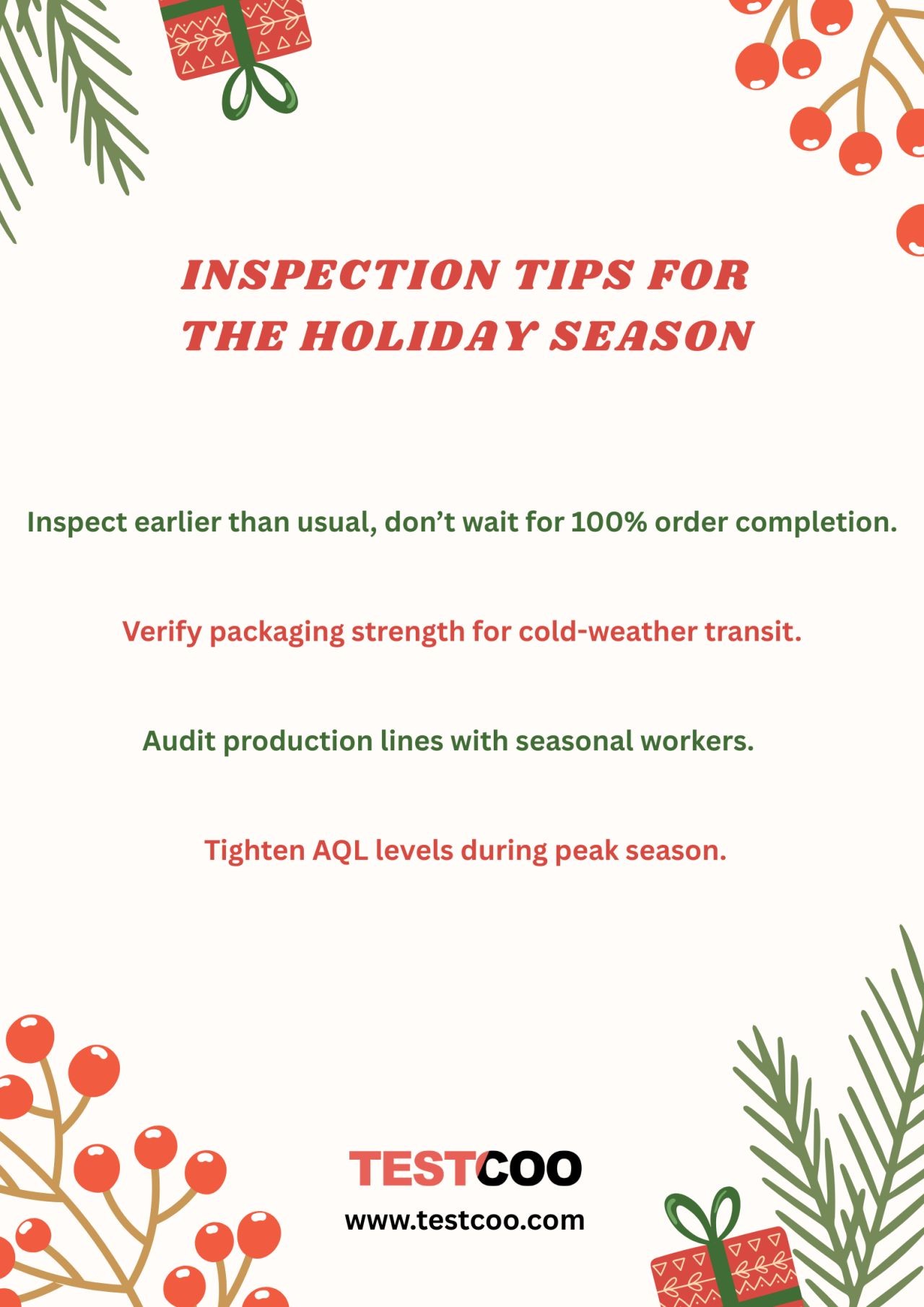

Winter is the most demanding season in global manufacturing, where tight deadlines, cold-weather risks and holiday-driven demand collide. Experienced buyers understand that quality failures during this period are far more costly than at any other time of the year. To protect seasonal sales, brand reputation and on-time deliveries, buyers strategically increase inspection frequency during winter months. By tightening quality checkpoints, adjusting inspection timing and focusing on winter-specific risks such as material brittleness, adhesive performance and packaging durability, buyers reduce the chances of last-minute rejections and post-shipment surprises. These best practices help ensure that products reach the market exactly as expected—when it matters most. Experienced buyers often:

- Increase inspection frequency in Q4

- Tighten AQL limits

- Add winter-specific quality parameters

- Insist on third-party verification

This proactive approach leads to:

- Fewer holiday disruptions

- Stronger supplier accountability

- Better year-end performance

Why Winter Inspections Are Non-Negotiable

Winter is the most unforgiving season for manufacturing and supply chains. Cold temperatures, fluctuating humidity and peak holiday demand place factories under intense pressure, increasing the likelihood of defects, delays and quality failures. Materials behave differently in low temperatures, packaging becomes vulnerable during transit and shortened production timelines leave little room for correction. In this high-risk environment, inspections are no longer a routine checkpoint—they are a critical safeguard. Winter inspections ensure products meet quality expectations before shipment, protecting brands from costly rework, returns and reputational damage when timing matters most. The holiday season is unforgiving. There are no second chances, no extended deadlines and no tolerance for quality failures.

Winter brings:

- Production pressure

- Environmental challenges

- Logistical constraints

- Heightened customer expectations

In this context, product inspections are not optional, they are essential. Testcoo helps brands safeguard product quality, meet seasonal deadlines and ship with confidence during the most critical time of the year.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index