What is a carton drop test? A Comprehensive Guide to Standards, Heights, and Processes

1. Understanding Carton Drop Test/Box Drop Test

Carton drop test, also known as box drop test, is a critical reliability test designed to simulate the impact and handling stresses that packaged goods might face during transportation. By dropping cartons from specified heights onto rigid surfaces, this test evaluates whether the packaging effectively protects the contents from damage. It helps manufacturers identify weaknesses in packaging design, ensuring products remain intact from factory to customer.

2. Key Standards for Carton Drop Testing

Industry-standardized protocols ensure consistency in drop test results. Some major global standards include:

1. ISTA 1A/2A: Focuses on single packages under 150 lbs, specifying drop heights based on weight. For example, a lighter package may have a higher drop height compared to a heavier one, as it is more likely to be handled in ways that could result in higher-impact drops during transportation.

Download the document about ISTA 1A here.

2. ASTM D5276: Defines procedures for determining the impact resistance of shipping containers. This standard is comprehensive, covering aspects such as the type of surfaces on which the container is dropped and the number of drops required for a valid test.

3. EN 22368-1: European standard for toy safety, including drop tests for children’s products. Since toys are often handled in a rough manner by children, this standard ensures that the packaging can protect the toys from damage during normal use and potential drops.

These standards outline test parameters, such as drop heights, surface types, and evaluation criteria, to ensure compliance with international shipping requirements.

3. Determining Drop Test Heights

The height of a carton drop test depends on the package’s total weight and the applicable standard. Common height guidelines include:

1. 0–20 lbs: 30 inches

2. 21–40 lbs: 24 inches

3. 41–60 lbs: 18 inches

4. 61–100 lbs: 12 inches

Heavier packages are dropped from lower heights to mimic real-world handling scenarios. For example, in a warehouse, a heavy box is less likely to be dropped from a great height as it is more difficult to lift and mishandle in such a way. On the other hand, lighter ones face higher drops to reflect potential mishandling risks. A small, lightweight package might be tossed around more carelessly during delivery, so a higher drop height in the test helps to ensure it can withstand such treatment.

4. Step-by-Step Drop Test Process

A typical drop test involves several stages:

- Pre-Test Inspection: Before starting the test, carefully verify the condition of the product inside the carton and the integrity of the packaging. Check for any pre-existing damages, loose parts, or improper sealing. For example, if the product is a delicate electronic device, ensure that all components are securely fastened within the packaging and that the carton has no visible tears or weak spots.

- Weight Measurement: Use a reliable weighing scale to determine the carton’s gross weight. This weight is crucial as it directly influences the drop height selection according to the established standards. Even a small difference in weight can lead to a different drop height, which in turn affects the test's accuracy.

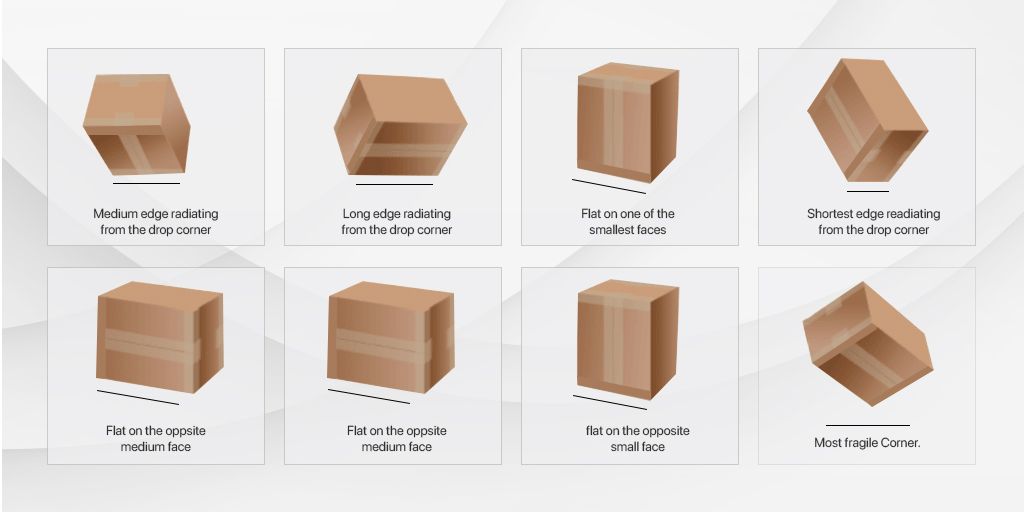

- Drop Sequence: One common method is the "1 corner, 3 edges, 6 faces" approach. First, identify the most vulnerable corner of the carton and drop it from the specified height onto a rigid surface. Then, move on to the three edges that radiate from the previously dropped corner, dropping the carton on each edge. Finally, drop the carton on each of the six faces. This comprehensive sequence helps to simulate various real-world drop scenarios that the package might encounter during transportation, such as being dropped on a corner when a worker loses their grip while carrying it or landing on a side during a forklift accident.

- Post-Test Evaluation: After all the drops are completed, conduct a thorough inspection. Check for any physical damage to the carton, such as tears, punctures, or crushed areas. Also, assess the structural integrity of the packaging to see if it can still protect the product effectively. For the product inside, check for functional issues. If it's a mechanical device, ensure all moving parts still operate smoothly. If it's a liquid-filled product, check for any leaks.

This systematic approach ensures a comprehensive assessment of packaging performance, allowing manufacturers to make informed decisions about their packaging designs. At Testcoo, we follow these steps meticulously in our carton drop test services, providing accurate and reliable results to help our clients improve their product packaging and reduce the risk of damage during transit.

5. Why Choose TESTCOO for Carton Drop Testing?

At Testcoo, we stand out as a leading provider of third-party quality control solutions, with a particular focus on professional carton drop testing. Our services are designed to meet and exceed your expectations, ensuring the highest level of quality and reliability for your packaging.

Customized Testing

We understand that every industry has its unique requirements. That's why our carton drop testing services are fully customized to align with your industry’s specific standards, such as ISTA, ASTM, or any other relevant guidelines. Whether you are in the electronics, food, or consumer goods industry, we tailor the test parameters to accurately simulate the real-world handling and transportation conditions your products are likely to encounter. For example, if you are shipping delicate electronic devices, we can adjust the drop test to replicate the rough handling that may occur during air freight, with higher drop heights and more stringent impact requirements.

Global Expertise

With certified technicians spread across over 30 countries, we offer a truly global service. Our team members are well-versed in international testing standards and have extensive experience in conducting carton drop tests. This global presence ensures that no matter where your products are manufactured or shipped from, you can expect consistent and accurate results. They stay updated with the latest industry trends and technological advancements, allowing us to provide you with the most relevant and up-to-date testing services. Whether it's a small-scale local production or a large-scale international shipment, our experts can handle it with precision.

End-to-End Solutions

TESTCOO offers more than just carton drop testing. We provide end-to-end solutions that cover every aspect of quality control. From pre-shipment inspections to ensure that your products are in perfect condition before leaving the factory to full compliance reports that detail the results of the testing process, we've got you covered. Our pre-shipment inspections involve a thorough examination of the product and its packaging, identifying any potential issues that could affect the outcome of the drop test or the integrity of the product during transit. The comprehensive compliance reports we generate are easy to understand and provide actionable insights, helping you make informed decisions about your packaging design and quality control strategies.

By choosing TESTCOO for your carton drop testing needs, you are entrusting your brand to a reliable partner. We are committed to validating the durability of your packaging and safeguarding your brand reputation. Our high-quality services help you avoid costly product damages during transportation, reduce returns, and enhance customer satisfaction. Let us be your go-to solution for all your carton drop testing requirements and experience the difference that professional, customized, and global quality control can make.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index