Down Garment Quality Control Inspections-Method and Checklist

Down garment Market is booming due to an increase in demand for down jacket from outdoor enthusiasts, rising popularity of at leisure wear and the growing disposable income of consumers in developing countries.

"According to Transparency Market Research, the global down jacket industry was valued at US$ 157.4 Bn in 2022 and it is estimated to advance at a CAGR of 12.8% from 2023 to 2031 and reach USS 456.0 Bn by the end of 2031.

Down jackets are thin, permeable, and have effective insulating qualities. An increase in the number of individuals engaging in outdoor activities such as skiing and snowboarding as well as other winter sports is expected to drive market development in the next few years.

All too frequently, this can result in consumer confusion and disappointment when the product they’re purchasing fails to live up to those claims.

Down garment importers and manufacturers are responsible for ensuring compliance with a range of standards and regulations.

What is Down Garment?

A down garment is a type of coat that is filled with the soft and insulating feathers of ducks or geese.

The strong warmth-to-weight ratio makes it feasible to stay comfortable in chilly, dry conditions. Insulated jacket's warmth is determined by the down's quality. The fill-power index, which usually falls between 300 and 900, is used to assess the quality of the down. Better (warmer) down results from a greater fill-power index.

It is usually made of a waterproof and windproof outer shell, with the feathers providing insulation. Down garment are very popular in cold weather climates, as they provide an excellent way to keep warm.

The Market of Down garment

Demand for down garments is rising, as more individuals participate in mountain sporting activities. Adventure sports, such as snowshoeing, mountaineering, camping, skiing, and trekking, are becoming more popular worldwide. This is anticipated to bolster industry growth.

North America is likely to lead the global down garment market in the period 2023-2029 Severe winter season and increase in popularity of adventure sports are contributing to the rise in demand for down garments in North America.

10 Prominent Players in Global Down Garment Industry

Some of the key players in the global down garment market are as follows:

Arc'teryx

Bosideng International Fashion (China) Co, Ltd.

Canada Goose Holdings Inc.

Giordano International Limited

HOdo Group Co, Ltd.

Marmot Mountain, LLC

Moncler S.p.A.

Patagonia, Inc.

The Columbia Sportswear Company

The North Face

Quality Control Inspections for Down Garments

Today quality is a keyword for consumers when it comes to purchase a down garment. Just like all textiles and apparel (Learn general garment inspection by Garments and Apparel Inspection), down garments must demonstrate compliance with regulations and mandatory specifications, including testing for down filling and down proof fabric. And it is also unknown if the down garments you imported comply with any safety requirements.

The importers and brands employ reliable third-party quality control Inspection Company to ensure the safety of down garments supply chain. Inspected down garments can contribute to increased consumer confidence in associated products and can help to strengthen brand reputation among both consumers and retailers.

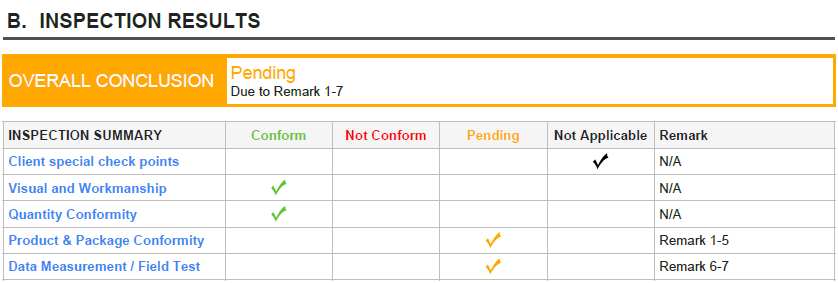

In most cases, a final random inspection for down jackets is performance to meet requirements of the customer. An on-site inspector focuses on these four checklists: visual and workmanship, quantity, product and package, data measurement and field test, sends a report with actual finds and garments pictures to clients when finishing the inspection.

Find out checklist to the down garments quality control and learn how to import down jacket that’s right for you in our down garments quality control inspection guide.

1. Visual and Workmanship Check for Down Garments Inspection

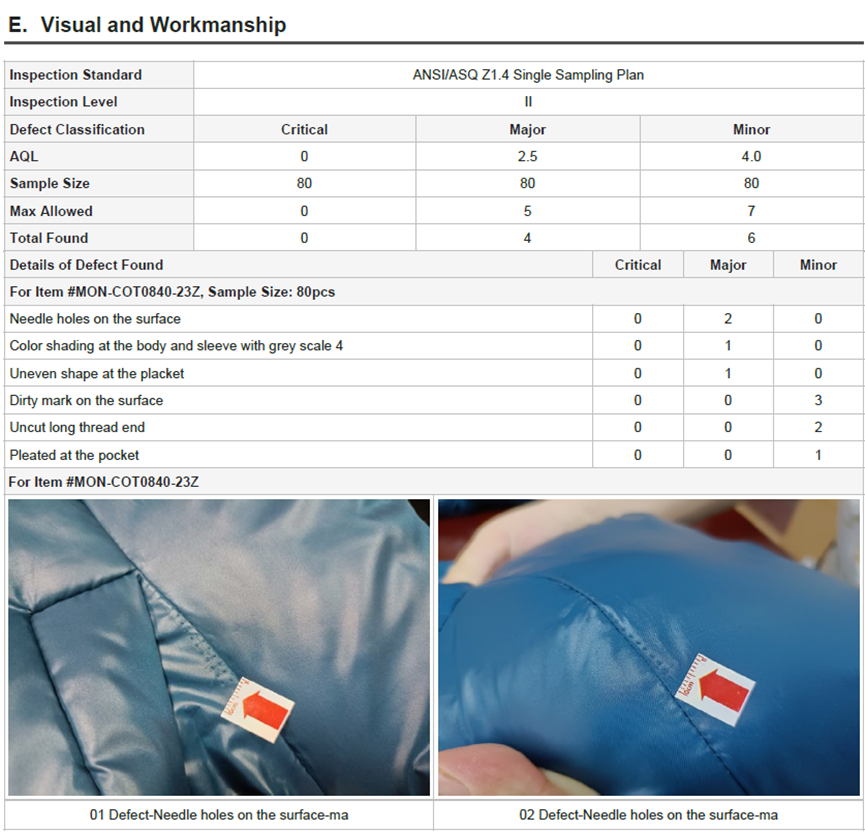

Among the quality control methods, inspection is the most-frequently used service and AQL standard is the most common way to select a sample for visual or appearance review.

AQL refers to the maximum number of defective items that could be considered to accept during the random sampling of pre-shipment inspection.

To reduce risk before accepting a shipment, AQL sampling is a practical and effective approach to undertake quality assurance on an order of produced items.

Generally, visual and workmanship check for down garments inspection per ANSI/ASQ Z1.4-2003 Single Sampling Plans for Normal Inspection, Inspection levelⅡ, Acceptable Quality Level (AQL) for: Critical defective: Not allowed; Major defective: 2.5; Minor defective : 4.0.

Discover more about AQL calculator, AQL table, AQL defects: Acceptable Quality Limit (AQL)

Inspectors check all selected samples against approval sample or spec, sort out the discrepancy if any with red arrow. All defectives must be sort out & put a red arrow on the position, classified as Critical / Major /Minor for a list summary.

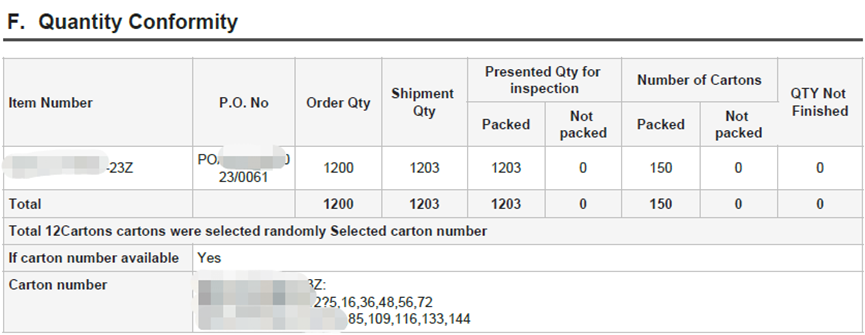

2. Quantity Conformity for Down garments Inspection

Inspectors verify the quantity of down jackets according to the PO / Booking, verify the shipment quantity, verify the quantity in warehouse. Take photo for stock, to shown the storage environment, verify whether any package damaged in stock, observe the bottom of the package.

3. Product and Packaging Check for Down Garments Inspection

Down garment must be accurately labeled and packaged. The actual amounts of down and feathers must not be misrepresented. It is especially important that labels meet with the market compliance.

-Check shipping mark, label, and barcode per item / PO against the spec and approval sample. Pay attention for the special requirement such as the recycle symbol, warning statement, as well as the GW/NW of carton.

-Package / Packing method check against spec.

-Gift box, hangtag, label, IM verified against spec.

- If there is polybag available, check the width of polybag and punched hole, to see whether meet the requirement of the warning statement.

-Focus on destination language, special requirement, claim match to the actual on the package.

4. Data Measurement and Field Test Checklist

Data measurement and field test checklist for down jackets:

- Carton drop test

- Assortment check

- Metal detection

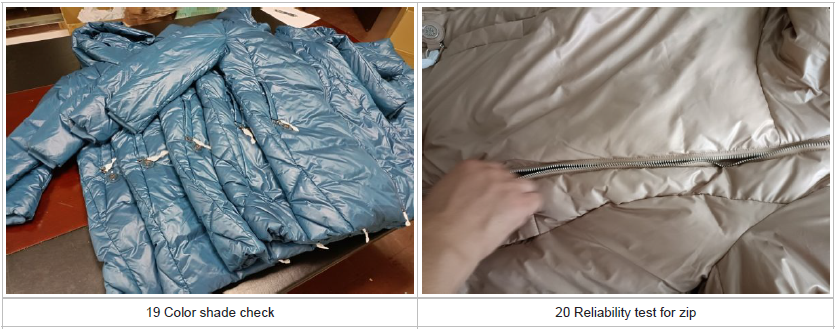

- Color shade check

- Reliability test for zipper/button/snap or any other functional component

- GSM test per fabric type

- Down garment size / weight measurement

- Tape test on printed label

- Fitting check

- Barcode scan check

- Seam elastic test

- Color fastness test

- Water proof test

- Stitching per 1cm check

Focus on down garment size measurement, function of closures and zippers, inner filling check, fabric GMS check, water proof test.

Read more: 14 Essential Garment Inspection Checklist in Quality Control

Conclusion: the Importance of Down Garments Quality Inspections

Down garment are light, breathable, and offer good insulating properties. Rise in number of people participating in outdoor activities, such as hiking, snowboarding, skiing, and other winter sports is also contributing to market development.

Third-party inspection has become a key part of many down garment importers’ supply chains. With an inspection team on the ground, you can see exactly how your products look without needing to personally visit the factory to check. But you need to clearly specify your requirements and steps for inspection to get a truly accurate report of your order’s quality.

Testcoo supports retailers, manufacturers, distributors and suppliers in the quality inspection of down jackets, coats, and clothing. Get in touch with Testcoo down garment and apaprel quality control expertise now!

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index