First Article Inspection Explained: Importance, Process and Benefits

Definition of FAI

The First Article Inspection (FAI) is a documented, detailed verification and comparison process performed on the first piece or batch of a new product or component manufactured using a specific process, material or tooling. The primary goal is to confirm that the manufacturing process can consistently produce parts that meet all design specifications and requirements before mass production begins.

In most cases, the supplier conducts the inspection, but the results are reviewed and approved by the customer or a Online Inspection Platform | Testcoo. The “first article” refers to the initial item(s) produced under a new or significantly modified process or contract.

Key characteristics of FAI:

- Comprehensive measurement and verification of all design features

- Documentation of results in standardized forms (e.g. AS9102)

- Comparison with engineering drawings, bill of materials (BOM), and specifications

- Often required in aerospace, automotive, medical devices, electronics, and other regulated industries

Why is FAI Necessary?

Prevents Mass Production Errors

Without FAI, undetected issues in the initial production stage could lead to thousands of defective products. The FAI checks for compliance at the earliest stage, allowing for corrections before mass production.

Ensures Compliance with Specifications

The FAI verifies every feature against the design documents and standards. It assures both manufacturers and customers that the products will perform as expected.

Reduces Costly Rework and Waste

By catching errors early, the FAI minimizes the risk of expensive rework or scrapping large volumes of parts.

Enhances Supplier and Customer Confidence

Documented FAI results demonstrate a supplier’s commitment to quality and reliability and build trust with customers.

Required by Industry Standards

Many industries, especially aerospace, automotive, electronics, and medical devices, mandate documented FAIs as part of their quality assurance processes.

Supports Process Improvement

FAI provides manufacturers with valuable data on their processes under real production conditions, offering opportunities to optimize methods or equipment.

Related article: Detailed explanation of third-party inspections: FAI

When Should FAI Be Conducted?

FAI is not a one-time activity for every production run; instead, it should be performed whenever there is a significant change that could affect part conformity. Common triggers include:

- New Product Introduction: When manufacturing a product for the first time.

- Change of Supplier or Manufacturing Location: Different facilities might use unique processes or materials.

- Design Changes: Any modification to drawings, specifications, or materials.

- Process or Tooling Changes: Modifications in manufacturing methods, machinery, or equipment.

- Material/Sub-supplier Changes: Introduction of new materials or sub-suppliers.

- Prolonged Production Gaps: Restarting production after an extended pause may require FAI to confirm continued conformity.

Each situation may require either a full FAI or a partial (delta) FAI, depending on the scope and impact of the change.

Related article: The Importance of Third-Party Quality Inspection

Types of First Article Inspection

FAI generally comes in two forms:

1. Standard/Full FAI

A complete inspection covering all drawings, dimensions, requirements, material certifications, and performance criteria for every feature of a part or assembly. This is required when:

- Producing a new part for the first time

- There are significant design or process changes

2. Partial/Delta FAI

Focused only on the features affected by specific changes, such as new tooling, minor design updates, or material changes, while referencing previous FAI records for unchanged features.

Summary Table

Type | Scope | When Required |

Full FAI | All features | New products/processes, major changes |

Partial/Delta | Changed features only | Minor updates, material/process adjustments |

The FAI Process Flow

A successful First Article Inspection involves several well-documented steps:

Step 1: Preparation

Gather Documentation:

- Engineering drawings (with all dimensions and tolerances)

- Digital product data sets (2D/3D models)

- Bill of Materials (BOM)

- Material certifications

- Process specifications

- Work orders and production routing sheets

- Supplier/sub-supplier information

Purpose: To ensure everyone understands the requirements and expectations for both product and process.

Step 2: Create an Inspection Plan

Tasks:

- Identify all features to be inspected

- Assign unique identifiers to each requirement on the drawing (“ballooning”)

- Complete standardized forms (e.g. AS9102 )

- Define measurement tools and test methods

- Categorize features by criticality

Purpose: To ensure systematic coverage and traceability of each requirement.

Step 3: Manufacture the First Article

Tasks:

- Produce initial sample using standard production processes

- Document any deviations or non-standard practices

- Record batch numbers and operator information

- Optionally involve third-party inspectors for objectivity

Step 4: Inspection and Data Collection

Tasks:

- Measure every identified feature with calibrated equipment

- Record results for each characteristic on the inspection report

- Note any non-conformities immediately

- Attach relevant certificates (material COC, test reports)

Step 5: Compile and Review the FAI Report

Tasks:

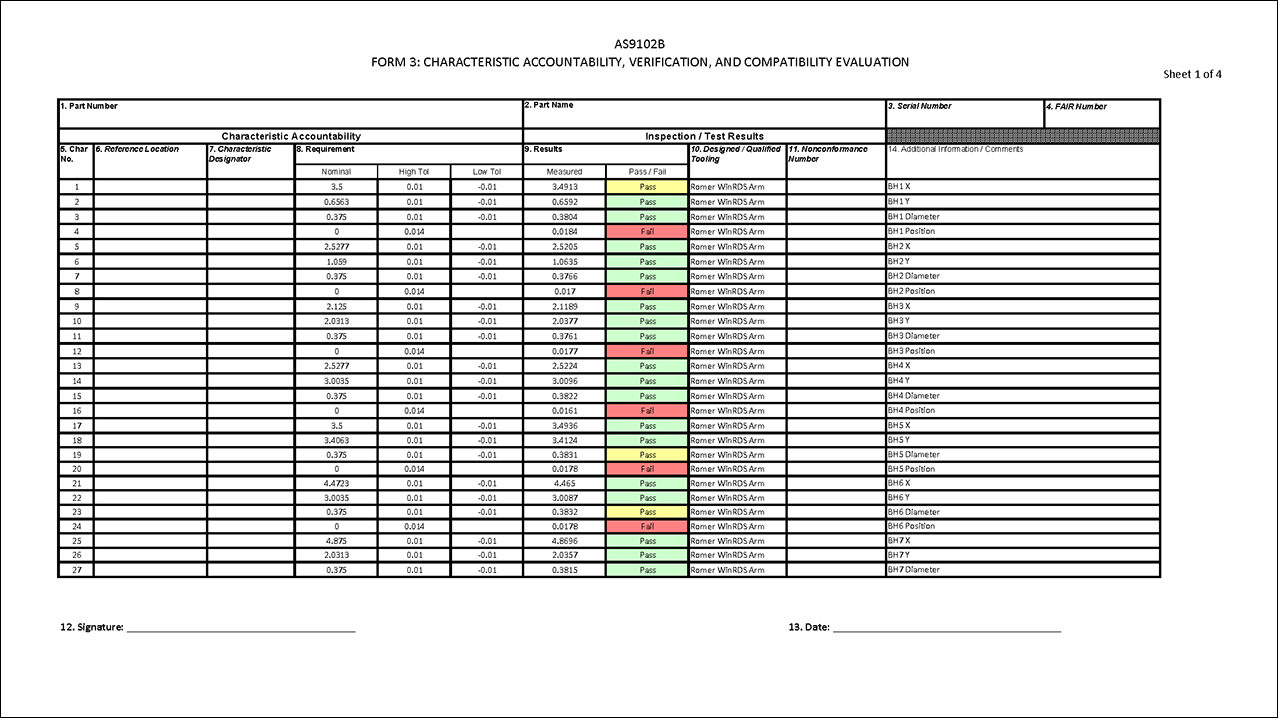

- Fill out all required forms (usually based on AS9102 standard)

- Form 1: Part number accountability

- Form 2: Product accountability (material & processes)

- Form 3: Characteristic accountability (measurement results)

- Attach supporting documents (drawings, photos, certificates)

- Submit report for customer review and approval

Purpose: Provides transparent evidence that all requirements have been met before authorizing full productio

What Happens If FAI Fails?

If a first article fails to meet any specification:

- Stop Production: Production is paused to prevent further nonconforming items.

- Root Cause Analysis: Investigate why the failure occurred (design error, process variation, material defect).

- Corrective Actions: Adjust design, tooling, process parameters, or material selection as needed.

- Re-inspection: Repeat the FAI process with a new sample to verify corrective actions are effective.

No full-scale manufacturing should proceed until a conforming first article passes inspection and approval.

The Role of Professional Inspection Services

While some manufacturers handle FAI internally, many companies, especially those with complex supply chains or offshore production, turn to third-party inspection services for objectivity and expertise.

Comprehensive Quality Services

Testcoo provides a full range of inspection services across diverse industries:

- Consumer Goods: Garments, footwear, toys, homeware

- Industrial Products: Machinery parts, building materials

- Electronics & Electricals: Components and finished goods

- Supplier Audits: Factory capability and compliance checks

- Lab Testing: Chemical analysis, safety tests

Standardized Processes

Third-party inspectors follow international standards (e.g.ISO9001, AS9102), ensuring consistent methodology regardless of location or supplier.

Unbiased Reporting

External inspectors provide impartial assessments that clients can trust, which is critical when resolving disputes or fulfilling regulatory obligations.

Advanced Technology Integration

Companies such as Testcoo use digital platforms to book inspections, track progress in real time, and analyze supplier performance data.

Cost Savings

By preventing large-scale defects and enabling rapid responses to issues, professional inspection services save clients substantial costs in rework, recalls, and lost reputation.

Customized Solutions

From single-product FAIs to ongoing production monitoring (In Production Check/IPC), companies tailor service packages to client needs, including video inspections and full-container loading supervision.

Related Inspection Services Throughout the Product Lifecycle

FAI is one pillar in a comprehensive quality control strategy. Other key services include:

Initial Production Check (IPC):

Inspection at the start of manufacturing to verify raw materials and setup.

Read More: Initial Production Check (IPC)

During Production Check (DUPRO):

Mid-production inspections to catch defects early.

Read More: During Production Check (DUPRO)

Final Random Inspection (FRI):

Sampling-based inspection after production is complete but before shipment.

Read More: Final Random Inspection for Consumer Goods Quality -TESTCOO

Loading Supervision (LS):

Ensures correct quantity and packaging during shipment loading.

Read More: Loading Supervision (LS)

Supplier Audits:

Evaluate factory capabilities, process controls, social responsibility compliance.

Read More: Supplier Audit & Supply Chain Compliance Solutions | Testcoo

Lab Testing:

Verifies compliance with safety standards and performance requirements.

How to Choose an FAI Inspection Company

Selecting a qualified inspection partner is key for accurate results and risk mitigation.

Considerations:

- Experience in your product category/industry

- Use of international standards

- Capability for both on-site and laboratory testing

- Transparent reporting system with traceable documentation

- Customer reviews and case studies

Testcoo offers one-stop solutions with over a decade of experience serving global importers, retailers, brands, and manufacturers.

Conclusion

First Article Inspection plays a critical role in global manufacturing, serving as more than just a process checkpoint. It lays the groundwork for consistent and dependable quality management. By verifying that each specification—covering materials, dimensions, and performance—is fully met in the initial production sample, manufacturers can prevent costly issues from arising later in the process.

Whether you are a buyer looking to ensure product reliability or a supplier aiming to build trust with clients, conducting comprehensive First Article Inspections and working with experienced inspection partners will strengthen your position in a competitive market. To support your supply chain at every step, including FAI and beyond, consider trusted service providers like Testcoo.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index