How to conduct quality control inspection for stand mixer by third party inspection China?

With most of the products supply chains located in countries far away from the brand buyers, it is important to ensure the products comply with both buyer requirements and market standards before they are shipped off to their destination. Therefore, to conduct a finished quality control inspections for kitchen stand mixer at the factory before shipping can ensure final product integrity and it is significant to brand buyers.

For a finished quality control inspection, Quality inspectors will evaluate the whole batch or randomly inspect one or more samples taken from the whole set to see whether all the products have been produced correctly following the specifications and requirements, which is called final random inspection, or FRI. Now let’s see how QC process finished quality control inspection for kitchen stand mixer from the original factory.

A finished quality control inspection checklist for stand mixer

1. Carton size/ weight check

Check the carton size and weight. Conformance per Spec. and printed information. If no specified tolerance, follow +/-5%.

2. Carton assortment and quantity check

Check the actual packing quantity/ color/ size/ style assortment which should confirm to printed information. For label and marking, make sure that the content is correct. Verify and check the rating labels on electrical components such as battery, cables, etc.

3. Product size /weight measurement /Power cord length check

Conformance per Spec. and printed information. If no specified tolerance, follow +/-3%.

4. Bar code scan check

Bar code must be able to be scanned correct as printed.

5. Assembly/ installation check

Should be assembled/ installed smoothly according to the instruction manual or guideline, and no issue is found.

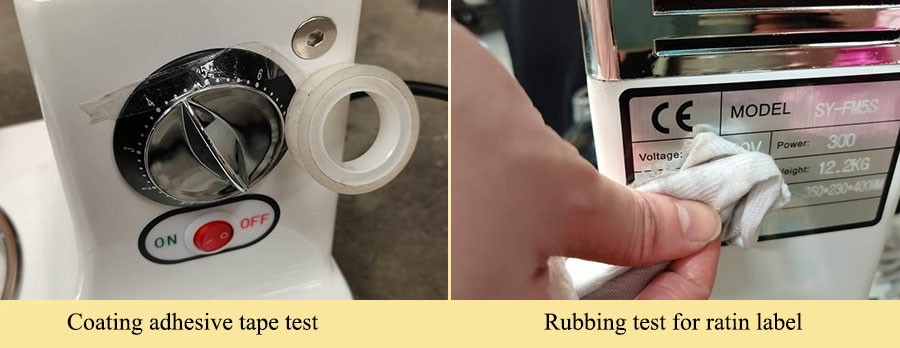

6. Coating adhesive tape test (also called “3M tape check”)

Place 3M 600( or same performance tape) tape for an adhesion test on all painting, foil stamping, UV coating and printing. No more than 10% peeled off area is required.

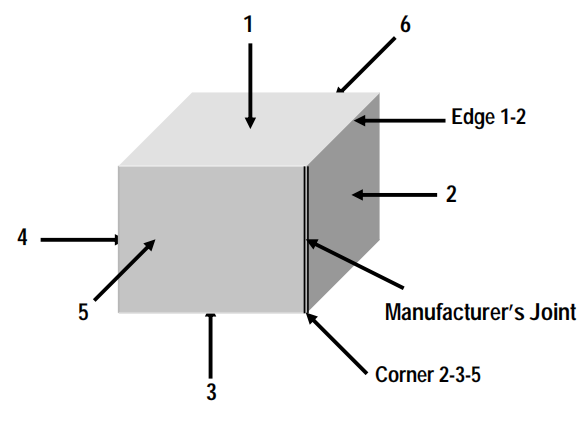

7. Rubbing test for ratin label and adhesive test for printing, marking and logo

Rub the rating label for 15 seconds with water, then for 15 seconds with petroleum spirits. If there is no failure, the test is passed.

8. High voltage test

Conduct the test for 1 second (5mA) at the voltage required between the tested parts (the voltage refer to the actual category product requirement or otherwise refer to below). The testing voltage required: for the USA/Canada markets: 1200Vac, for European markets: class I 1000Vac, class II 2500Vac. No insulation breakdown.

9. Power on check

The good condition samples should be operating at full load (preferable) at least 4 hours at rated voltage or time referred to the user instruction if less than 4 hours. After testing, the samples should pass the high voltage check, function check, earth continuity check etc., and no defect is found.

10. Power consumption check or input power/ current check (without load)

The power consumption /input power /current must comply with product spec. and safety standard. Normally the tolerance should be between +5% and -10%.

11. Strain relief test

To test the strain relief of the power code, use a force of 100N and the cord should not be displaced more than 2mm. UL standard: pull on the cord for 35 lb for 1 min, the cord should not be displaced.

12. Internal workmanship and critical component check

Check internal construction complement and main components according with CDF (Constructional Data Form) or CCL (Critical Components List).

13. Motor locking check

Lock the motor of the mixer under rated voltage, it should not pose a hazard to the users and the surroundings. The shell of mixer should not be ignited or burned. No molten metal appears.

14. Stability test (for freely standing unit)

Place the sample on an inclined surface at 10 degrees (15 degrees for heating appliances) to the horizontal surface. The power cord should be placed in the most unfavorable position and the appliance should not tip over.

15. Full function check (including the function which only can be checked after fully assembling)

All captioned function is well conducted as intended, such as installation/ adjusting, switch/ knob action check, setting, display, actual using function etc. All of function should be complied with claims.

16. Noise test

The noise does not exceed 85 decibels at a distance of 1 meter.

17. Smell test

No unwanted bad or irritative smell while the mixer is working or powered off.

18. Transportation drop test

According to ISTA 1A standard, the product and package should be free of critical and serious problems after test. The test drop height varies with the weight of the packaged-product. For example, the stand mixer is about 15kg, greater than 10kg but less than 19kg, then the test drop height is 24in. For more details, refer to: How to determine the test drop height of a product by ISTA 1A standard ?

After the above field tests and everything is labelled and documented correctly, the inspector will produce a final inspection report that will enable purchaser to take immediate and early action if anything is incorrect. Read electrical inspection report samples here.

Quality inspection is important for your kitchen stand mixer

Today, using third party inspection companies is more convenient with a lower price to ensure your products meet your customers’ expectations including materials, style, function, etc.

As a third party inspection company with intelligent management for quality assurance, TESTCOO aims to build the world’ s most influential third-party inspection service center and TESTCOO QC team are with extensive experience in various manufacturing processes. Contact TESTCOO and you can make an inspection order in 5 minutes and get your detailed report in 48 hours.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index