Why Quality Inspection of Pet Products Matters: A Closer Look

The Rising Concern for Pet Product Quality

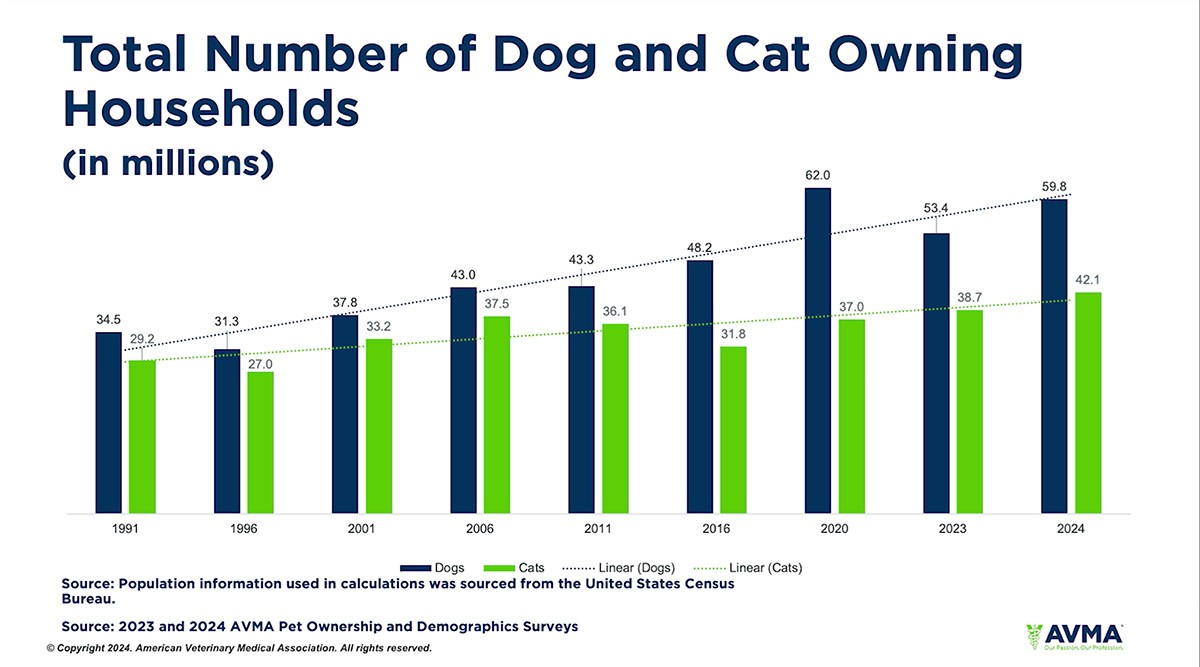

Pet ownership has been steadily increasing, with 70% of U.S. households, or 90.5 million homes, owning a pet in 2023, according to the American Pet Products Association (APPA). This rise in pet ownership has led to a booming demand for pet products, from food and treats to toys, bedding, and healthcare items. However, this growth has also brought concerns over product quality. There have been several high-profile recalls, including pet food contaminated with melamine and toys made from hazardous materials. These incidents have not only harmed pets but also shaken consumer confidence in the industry.

Learn more data about the industry:Leading Pet Industry Association | American Pet Products Association

Common Quality Issues in Pet Products

Food Safety

Food safety is a primary concern when it comes to pet products. Pet food is expected to meet specific nutritional requirements to ensure the well-being of pets. However, many pet food products on the market fail to meet these standards. For instance, some pet foods may not contain the proper balance of proteins, fats, vitamins, and minerals that pets need for optimal health. Inadequate protein levels can lead to muscle loss and a weakened immune system in pets, while a lack of essential vitamins like vitamin D can cause bone-related problems.

Additives are another area of concern. Some pet food manufacturers may use illegal or excessive additives. For example, certain artificial colors and flavors that are used to make pet food more appealing to owners may have negative impacts on the pet's health in the long run. These additives can potentially cause allergic reactions, digestive problems, and even more serious health issues over time.

Contamination is also a major problem in pet food. There have been cases where pet food has been contaminated with harmful substances such as melamine, bacteria like Salmonella, or heavy metals. Melamine, as mentioned before, was infamously added to some pet food products in the past to falsely inflate the protein content. When ingested by pets, it can form crystals in the kidneys, leading to kidney failure. Salmonella contamination in pet food can cause vomiting, diarrhea, and fever in pets, and it can even be transmitted to humans, especially those with weakened immune systems. Heavy metal contamination, such as lead or mercury, can have long-term neurological and developmental effects on pets.

↵

Material and Durability

The materials used in pet products play a crucial role in their safety and quality. For pet toys, they should be made of non-toxic and safe materials. For example, rubber toys should be free from harmful chemicals like phthalates, which are often found in low-quality plastics. Phthalates can be absorbed by pets when they chew on toys, potentially leading to hormonal imbalances and other health problems.

Durability is another significant factor. A durable pet toy can withstand the rough play of pets. However, many pet toys on the market are not durable enough. For instance, some soft, plush toys may easily tear apart, and the stuffing inside can be ingested by pets, causing intestinal blockages. There have been reports of pets needing emergency veterinary care due to swallowing the stuffing from ripped-apart toys.

When it comes to pet bedding, the materials should be soft, comfortable, and hypoallergenic. Some cheap pet beds may be made of materials that can cause skin irritations in pets. For example, certain synthetic fibers may not be breathable, leading to overheating and skin problems for pets. Additionally, the durability of pet bedding is important. If the seams are not well stitched, the bed can quickly fall apart, leaving the pet without a comfortable place to rest. There have been cases where pet owners were disappointed when their pet's bed became unusable after just a few weeks of use due to poor construction and low-quality materials.

Importance of Quality Inspection

Protecting Pet Health

Quality inspection of pet products is of utmost importance when it comes to safeguarding the health of our furry companions. Pets are vulnerable to the quality of the products they consume or interact with. For example, a pet that regularly consumes low-quality pet food may experience malnutrition over time. The lack of essential nutrients can lead to a weakened immune system, making the pet more susceptible to diseases. A study by the Journal of Veterinary Internal Medicine found that pets fed with nutritionally deficient food are 30% more likely to develop chronic health conditions compared to those on a balanced diet.

In terms of pet toys, if they are not made of safe materials, they can cause serious harm to pets. A pet chewing on a toy made of toxic materials may ingest harmful substances. These substances can then accumulate in the pet's body and lead to various health problems, such as liver and kidney damage. For instance, some cheap rubber toys may contain lead or other heavy metals, which can be extremely dangerous when ingested by pets. Quality inspection helps to ensure that pet toys are made from nontoxic, pet-friendly materials, reducing the risk of such health hazards.

Ensuring Consumer Rights

Quality inspection also plays a crucial role in protecting consumer rights. In the pet product market, consumers rely on accurate information about the quality of products. When a product passes a strict quality inspection, it provides consumers with the assurance that they are getting what they pay for. For example, a pet owner who purchases a high - quality pet bed expects it to be durable, comfortable, and safe for their pet. Through quality inspection, products that meet these standards can be identified, and consumers can make informed purchasing decisions.

Without proper quality inspection, consumers may unknowingly purchase substandard products, resulting in financial losses. For instance, a pet owner who buys a pet food brand that claims to be high-quality but fails to meet the nutritional requirements is essentially wasting their money. Quality inspection helps to maintain market fairness by ensuring that only products that meet the required standards are sold. It also encourages manufacturers to produce high-quality products, as they know that their products will be subject to strict inspection. This, in turn, benefits consumers as they have access to a wider range of safe and reliable pet products. At Testcoo, we are committed to providing comprehensive quality inspection services for pet products, helping both pet owners and manufacturers ensure the safety and quality of pet products in the market.

The Process of Pet Product Quality Inspection

Sampling

Sampling is the initial and crucial step in pet product quality inspection. It involves the selection of a representative subset of products from a larger batch. The principle behind sampling is to ensure that the sample accurately reflects the quality characteristics of the entire population of products. For example, in pet food, a proper sampling method would involve randomly selecting packages from different production lots, different storage areas in the warehouse, and different parts of the production line. This helps to capture any potential variations in the product quality.

If the sampling is not done correctly, it can lead to inaccurate inspection results. For instance, if samples are only taken from the top layer of a stack of pet food bags in a warehouse, it may not represent the quality of the entire batch, as there could be differences in temperature, humidity exposure, or packaging integrity between the top and bottom layers. To ensure the reliability of sampling, statistical sampling methods are often employed. These methods use probability theory to determine the appropriate sample size and selection process. For example, the simple random sampling method gives every unit in the population an equal chance of being selected, which helps to minimize bias in the sampling process.

Laboratory Testing

Laboratory testing is a comprehensive and in-depth part of the quality inspection process. For pet food, one of the common tests is nutritional composition analysis. This includes measuring the levels of proteins, fats, carbohydrates, vitamins, and minerals. For example, proteins are essential for muscle development in pets, and their accurate measurement is crucial. The standard methods for protein analysis often involve the Kjeldahl method or the Dumas method, which determine the nitrogen content in the sample and then calculate the protein content based on the nitrogen-protein conversion factor.

In the case of pet toys, laboratory testing focuses on aspects such as material safety. For example, testing for the presence of phthalates in plastic toys is essential. Phthalates are a group of chemicals often used in plastics to increase flexibility, but they can be harmful to pets if ingested. The testing for phthalates typically involves extraction of the chemical from the toy material followed by analysis using gas chromatography-mass spectrometry (GC-MS). The limits for phthalates in pet toys are often set by international standards, such as those defined by the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation.

Quickly check more European Union REACH regulations here.

Field Testing

Field testing, also known as real-world or in-use testing, is an essential part of pet product quality inspection. This type of testing aims to evaluate how pet products perform in actual, everyday situations. For pet toys, field testing may involve observing how different types of pets interact with the toys. For example, a dog-specific toy may be tested with various breeds of dogs of different ages and sizes. A small-breed puppy may have different chewing and playing habits compared to a large-breed adult dog. By observing these interactions, manufacturers and quality inspectors can identify potential issues such as whether the toy is too small and could be a choking hazard or if the material is not durable enough to withstand the dog's chewing force.

For pet bedding, field testing would involve placing the bedding in the pet's normal living environment. This allows for the assessment of factors such as comfort, ease of cleaning, and durability in a real-life setting. For example, a pet owner may report that the bedding material is too slippery for their pet to rest comfortably, or that it stains easily and is difficult to clean. These real-world observations can provide valuable insights that may not be apparent from laboratory testing alone. Field testing also helps to ensure that the product meets the practical needs of pet owners. A pet product that performs well in the laboratory but fails to meet the convenience and functionality requirements of pet owners in daily use is not a successful product.

How Testcoo Can Help

At Testcoo, we are committed to providing top-notch quality inspection services for pet products. Our professional team consists of highly trained inspectors who have in-depth knowledge of pet product quality standards and regulations. They are well-versed in the various aspects of pet product inspection, from raw material checks to final product testing.

Equipped with state-of-the-art testing equipment, we can conduct a wide range of tests accurately and efficiently. For example, our advanced chemical analysis instruments can precisely detect the presence and concentration of various substances in pet products, ensuring that no harmful chemicals are present. Our physical testing equipment can simulate reallife usage scenarios to test the durability and safety of pet toys and accessories.

Our inspection services cover a comprehensive range of pet products. Whether it's pet food, where we check the nutritional content, ingredient quality, and absence of contaminants; Pet toys, for which we assess safety, durability, and functionality; Or pet care products like shampoos and conditioners, where we test for skin-friendliness and chemical safety, we have you covered.

If you are a pet product manufacturer, distributor, or retailer, partnering with Testcoo can give you peace of mind. We can help you ensure that your products meet the highest quality standards, protect your brand reputation, and most importantly, safeguard the health and well-being of the pets that use your products. Contact us today to learn more about how our services can be tailored to your specific needs and take the first step towards ensuring the quality of your pet products.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index