The Ultimate Guide to Footwear Inspection: Your Questions Answered

In the global footwear industry, where competition is fierce and consumer expectations are higher than ever, quality inspection stands as the critical gatekeeper between production and the marketplace. A single defective pair of shoes can lead to returns, reputational damage and even safety liabilities. Footwear inspection is not merely a procedural step, it is a strategic function that ensures product integrity, brand credibility and customer trust. This comprehensive guide answers the key questions surrounding footwear inspection, offering insights for brands, retailers, sourcing professionals and quality assurance teams.

Why Is Footwear Inspection Non-Negotiable?

1. How Does Inspection Protect Your Brand Reputation?

In the age of social media and online reviews, a single product failure can go viral. Stitching that unravels, soles that separate or materials that fade unexpectedly can erode consumer confidence overnight. Consistent quality is a silent ambassador of your brand.

2. What Role Does Inspection Play in Consumer Safety?

Footwear is a functional product. Defects can lead to trips, falls or long-term foot health issues. Children’s footwear, in particular, is subject to stringent safety standards regarding small parts, chemical content and structural integrity.

3. How Does Inspection Reduce Costs from Returns and Recalls?

The cost of a recall or a wave of returns far exceeds the investment in thorough inspection. Preventing defective goods from reaching the market is always more economical than dealing with the aftermath.

4. How Does Inspection Ensure Compliance with Standards and Regulations?

From ISO standards to country-specific regulations (like CPSIA in the USA or REACH in the EU), footwear must comply with a web of legal requirements. Inspection verifies compliance, avoiding customs holds, fines or seizure of goods.

5. Can Inspection Drive Continuous Improvement in Manufacturing?

Inspection data is a goldmine. Patterns in defects feed back into the production process, helping factories identify root causes in machinery, worker training or material sourcing, fostering a cycle of continuous improvement.

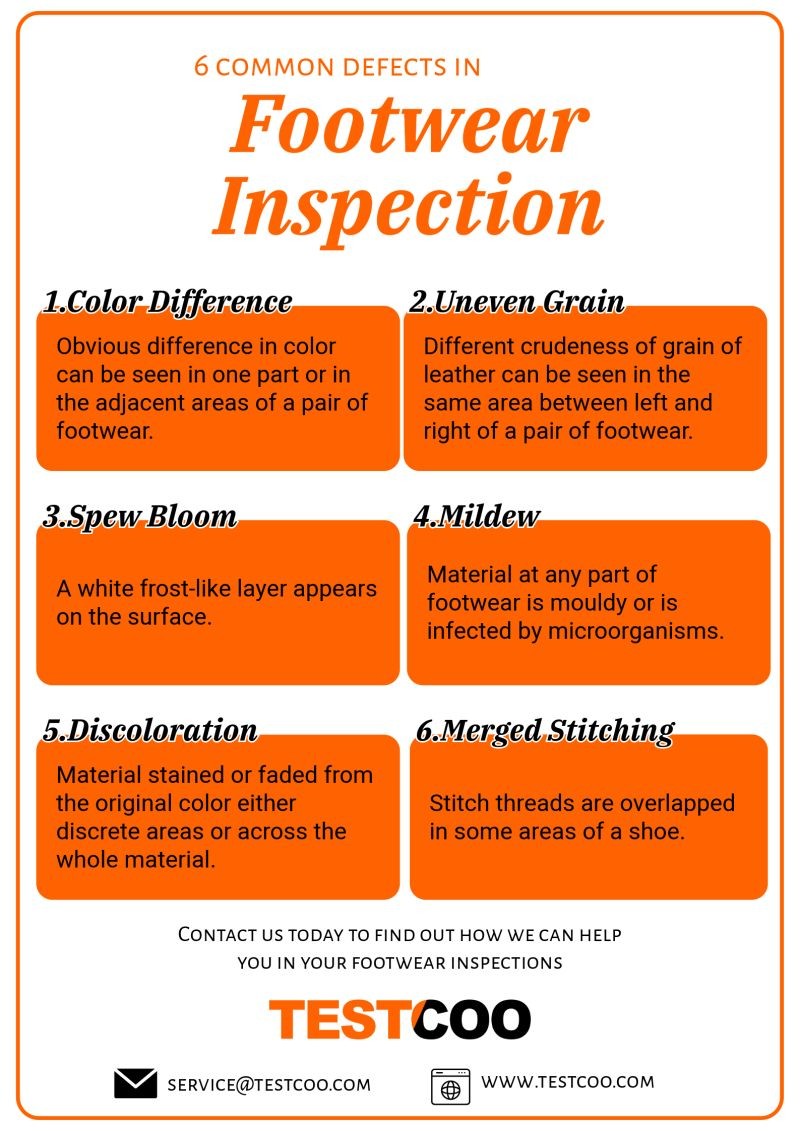

Read more: A List of Defects during Visual Inspection in Footwear Quality Control

What Are the Four Pillars of Footwear Inspection?

A robust inspection regime rests on four key pillars, often implemented at different stages of production.

1. What Is Initial Production Check (IPC)?

Initial Production Check (IPC) occurs before mass production begins.

- Purpose: To verify that all inputs are correct and ready, preventing mass production based on a faulty foundation.

- Focus Areas:

- Raw Materials: Leather, textiles, rubber, foams, adhesives, dyes and hardware (buckles, eyelets). Checks include thickness, color, grain, tensile strength and compliance with safety standards (e.g., free of azo dyes, heavy metals).

- Components: Outsourced soles, insoles, heels. Check dimensions, durometer (hardness), color and bonding surfaces.

- Approved Prototype & Specifications: Confirm that the factory's technical packs, patterns and last (the foot-shaped form) match the approved sample.

- Production Line Setup: Ensure machinery is calibrated and workers are briefed on the correct standards.

2. What Is During Production Inspection (DUPRO)?

During Production Inspection (DUPRO) takes place when 10-20% of the order is complete on the production line.

- Purpose: To identify defects early in the run, allowing for real-time corrections before the entire order is compromised.

- Focus Areas:

- Workmanship Consistency: Are stitching, gluing and assembling techniques consistent across multiple units?

- Color and Material Matching: Do all cut parts match in shade and grain? Is there any contamination or damage?

- Line Efficiency & Process Control: Observing the assembly line to spot procedural errors.

Read more: Caught in the Middle: How During Production Inspection Safeguards Your Supply Chain

3. What Happens During a Final Random Inspection (FRI)?

Final Random Inspection (FRI) is the most common and critical inspection, conducted when 80-100% of the order is packed and ready for shipment.

- Purpose: To provide a final statistical representation of the entire order's quality and determine if it is acceptable for shipment.

- Methodology: Based on ANSI/ASQ Z1.4 or similar statistical sampling plans. Inspectors randomly select a sample size from the bulk order. The number of major and minor defects found determines if the batch passes, fails or requires sorting/repair.

- The "AQL" Standard: The Acceptable Quality Limit (AQL) is the cornerstone of FRI. It defines the maximum number of defects considered acceptable. For footwear:

- Critical Defects (AQL 0): Safety issues or functional failures. Zero tolerance.

- Major Defects (AQL 1.5-2.5): Defects affecting usability, durability or appearance (e.g., open seams, incorrect sizing, severe discoloration).

- Minor Defects (AQL 4.0): Small flaws not affecting function (e.g., slight uneven stitching, minor smudges).

Read more: Final Random Inspection: Your Last Line of Defense Before Shipping

4. Why Is Loading Supervision (LS) Important?

Loading Supervision (LS) is a final safeguard during the loading of shipping containers.

- Purpose: To verify correct quantities, prevent mixing of orders and ensure packing is done to prevent transit damage.

- Focus Areas: Carton condition, shipping marks, packing list accuracy and proper loading to avoid crushing or moisture damage.

Read more: Container Loading Inspection for Safer Shipments

What Does a Detailed Footwear Inspection Checklist Include?

A professional inspector will systematically examine a shoe from multiple angles. Here’s what they look for:

1. What Is Checked in Visual & Dimensional Review?

- Overall Appearance & Symmetry: Do the left and right shoes match in shape, height and proportion?

- Dimensions & Sizing: Measure outsole length, insole length and critical girths. Compare against spec sheet and size chart.

- Lasting & Shape: Is the upper smoothly stretched over the last without wrinkles or distortion?

2. How Are Upper Materials & Construction Inspected?

- Leather/Textile Quality: Check for grain consistency, scars, pores, color evenness and tensile strength.

- Cutting: Are parts cut cleanly or is there fraying or notching?

- Stitching: SPI (stitches per inch), consistency, tension, missed stitches, broken threads and correct thread color.

- Gluing: Neat, even application with no overflow or "glue ghosts." Check bonding strength.

- Reinforcements: Heel counters, toe puffs and quarter linings properly positioned and secure.

3. What Is Involved in Sole Unit & Bottoming Inspection?

- Sole Attachment: Is the sole securely bonded or stitched? Check for separation gaps.

- Outsole: Check pattern, thickness, hardness and wear properties.

- Midsole/Insole: Check for proper cushioning, arch support positioning and any wrinkles or air pockets.

- Heel: Secure attachment, height alignment and top piece finish.

4. How Is Fitting & Functionality Tested?

- Lace-up/Closure Systems: Do eyelets, hooks or D-rings function smoothly? Does the Velcro hold securely?

- Lining & Padding: Check for smooth seams, even padding distribution and no loose material inside.

- Comfort & Flex: Manually flex the shoe to check for proper bending at the ball and to ensure no cracking sounds from the adhesive.

5. What Falls Under Finishing & Trimming Checks?

- Excess Material: All loose threads, excess glue and mold flash (on rubber soles) must be cleanly trimmed.

- Polishing & Cleaning: Upper surfaces should be free of dust, stains or finishing residues.

- Branding & Logos: Accuracy, alignment and quality of embossing, debossing, labels and hangtags.

6. Why Is Packaging & Presentation Inspected?

- Individual Packaging: Are shoes correctly positioned in tissue paper? Are shoe trees, dust bags or accessories included?

- Barcode & Labeling: Are size, SKU, country of origin and care labels correct and legible?

- Shipping Carton: Carton strength, correct shipping marks and accurate packing list.

Read more: Inside a Product Inspection Checklist: Your Guide to Quality Control

How Does Inspection Differ by Footwear Type?

- Safety & Work Boots: Heightened focus on puncture-resistant plates, electrical hazard ratings, toe cap impact tests and slip-resistant outsoles.

- Athletic & Running Shoes: Critical inspection of advanced cushioning systems (air bags, gel), seamless uppers and the integrity of bonded overlays which undergo extreme stress.

- Leather Dress Shoes: Unforgiving scrutiny of leather grain, patina, broguing detail and the quality of Goodyear welting or Blake stitching.

- Children's Footwear: Mandatory safety checks for small parts (pull tests), sharp points/edges and chemical testing for phthalates, lead, etc.

- Fashion & Seasonal Footwear: Focus shifts heavily to aesthetic perfection, color vibrancy and decorative element security (sequins, beads, etc.).

What Is the Future of Inspection: Human or Machine?

While the human eye and trained hand are irreplaceable for overall judgment and tactile checks, technology is revolutionizing inspection.

- 3D Scanning & Metrology: For precise dimensional analysis of lasts and finished shoes against CAD models.

- Automated Vision Systems: Cameras and AI can now detect stitching defects, color variations and surface flaws at high speed on the production line.

- Material Testing Labs: On-site or third-party labs conduct objective tests for colorfastness, tear strength, adhesive bond strength and chemical compliance.

The future lies in a hybrid approach: technology for repeatable, data-rich measurements and human inspectors for holistic quality judgment and root-cause analysis.

What Are the Biggest Challenges in Modern Footwear Inspection?

- Globalized & Complex Supply Chains: Multiple component suppliers across different countries make traceability and consistent quality a challenge.

- Pressure on Cost & Speed: The fast-fashion cycle pressures factories to cut corners. Inspectors must be the unwavering voice for quality standards.

- Subjectivity in Aesthetics: Some defects (like natural leather markings) fall into a gray area. Clear, agreed-upon "limit samples" between brand and factory are essential.

- The "Friday Shoe" Phenomenon: Quality can dip at the end of shifts or weeks. Random, unannounced inspections are crucial to combat this.

Read more: From Stitching to Soles: Key Quality Checks in Footwear Inspection

Frequently Asked Questions (FAQ)

1. What is AQL and why is it important in footwear inspection?

AQL (Acceptable Quality Limit) is a statistical sampling standard used in pre-shipment inspections to determine if a batch of products meets quality requirements. It defines the maximum number of defects allowed in a random sample. For footwear, critical defects have an AQL of 0 (zero tolerance), major defects typically have an AQL of 1.5-2.5 and minor defects have an AQL of 4.0. It provides an objective, data-driven way to accept or reject shipments.

2. When is the best time to conduct a footwear inspection?

The most effective quality control uses multiple inspection points: 1) Pre-Production to verify materials and setup, 2) During Production (at 10-20% completion) to catch issues early and 3) Pre-Shipment (at 80-100% packed) for the final acceptance decision. For high-risk orders or new factories, all three stages are recommended.

3. What's the difference between in-house and third-party inspection?

In-house inspection is conducted by your own quality staff and offers direct control and brand-specific knowledge. Third-party inspection provides independent, unbiased verification, specialized expertise across multiple factories and often global reach. Many brands use a hybrid approach for optimal coverage and objectivity.

4. How are specialized footwear types (like safety boots) inspected differently?

Specialized footwear requires additional, rigorous checks beyond standard aesthetics and construction. For safety boots, this includes lab tests for toe cap impact resistance, puncture protection, electrical hazard ratings and slip resistance. Athletic shoes need stress tests for cushioning systems, while children's shoes require mandatory chemical and small parts safety testing.

5. Can inspection really prevent all defective products from reaching customers?

While thorough inspection significantly reduces the risk, it cannot guarantee 100% perfection due to statistical sampling nature. However, a robust multi-stage inspection program catches the vast majority of issues, prevents systematic failures and provides data to continuously improve the production process, ultimately minimizing customer-facing defects to extremely low levels.

Conclusion: Is Inspection a Cost or an Investment?

Footwear inspection should not be viewed as a policing activity, but as a cornerstone of a successful brand-factory partnership. By investing in a multi-stage, detailed and data-driven inspection process by Testcoo, brands can:

- Ship with Confidence, knowing their products meet the promised standard.

- Build Trust with consumers who become loyal advocates.

- Empower Factories with clear feedback to improve their processes.

- Protect Their Bottom Line by avoiding the catastrophic costs of failure.

In the end, every stitch checked, every sole measured and every pair approved is a step towards building a brand that stands the test of time and wear.

Looking to develop a customized footwear inspection protocol for your brand? Contact us today.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index