A List of Defects during Visual Inspection in Footwear Quality Control

A List of Defects during Visual Inspection in Footwear Quality Control

General defects of footwear quality control on-site inspection

On-site and appearance inspection is important for manufacturer, supplier, inspection organization and costumer etc. to examine footwear inspection quality. Conducting pre-shipment footwear quality control inspection click: Footwear quality control inspection: essential checklist for shoes to learn more.

Keep in mind that the presence of one or other of these defects in footwear does not automatically imply that the footwear is substandard. Suppliers and purchasers will still reach agreement on the acceptance of goods provided the limits of the defects and allowance have been made, bearing in mind the intended use of the footwear.

General defects

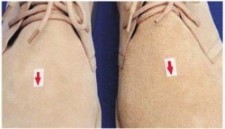

1 Color difference

Obvious difference in color can be seen in the same area between left and right of a pair of footwear or in one part or in the adjacent areas of a pair of footwear

Note 1 to entry: This defect doesn’t include design purpose.

2 Uneven grain

Different crudeness of grain of leather can be seen in the same area between left and right of a pair of footwear.

3 Spew bloom

A white frost-like layer appears on the surface.

4 Mildew

Material at any part of footwear is mouldy or is infected by microorganisms.

5 discoloration

Material stained or faded from the original color either discrete areas or across the whole material.

6 Merged stitching

Stitch threads are overlapped in some areas of a shoe.

7 Skipped stitching

Thread is skipped and pinhole is left in shoe.

8 Crooked stitching

Parallel alignment of between stitch line and intended edge on an upper is disordered or crooked.

Note 1 to entry: special stitching style shall be excluded from crooked stitch.

9 Exposed ground stitching

Ground stitching is exposed on the upper surface and next to the upper stitching line.

10 Adhesion failure

Two parts assembled by adhesive material (such as cement) are detached

Note 1 to entry: Typical adhesion failures are between out soleand midsole, between outsole and upper, also between midsole and upper.

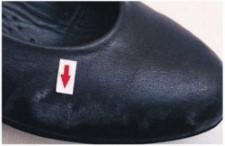

11 Colour migration

Colour migrates from one part of footwear to another part.

12 Stitching failure

Two parts assembled are detached of the stitched components.

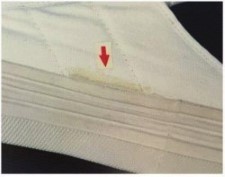

13 Excessive glue

Adhesive bleeds from adhesion part to the surface.

14 Textile broken

Any textile footwear component is broken.

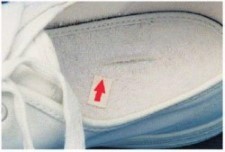

15 Crease wrinkle

A permanent hard folding mark appears in the middle of fabric, like a pleat or furrow in the surface which may be stuck together.

Partnering with a third-party inspection enables you to identify and control quality concerns at the source. Contact our footwear quality assurance experts to customize your inspection requirements and receive within 24 hours of our detailed inspection reports that you can see images of any defects found as if you’re in the factory check the shoed yourself.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index