The Comprehensive Guide to Apparel Defects: Types, Causes, Solutions, and Prevention

The global apparel industry thrives on creativity, precision, and customer satisfaction. However, defects in garments can pose significant challenges to businesses. Apparel defects not only lead to operational inefficiencies but also tarnish brand reputation and result in financial losses. With increasing consumer demand for quality, the importance of defect-free production cannot be overstated.

In this guide, we’ll cover everything you need to know about apparel defects, including their types, causes, consequences, solutions, and preventive measures. We'll also delve into the critical role of third-party inspection services like Testcoo in managing consistent apparel quality control across the supply chain.

What Are Apparel Defects?

Apparel defects are imperfections or flaws in garments that occur during the production process. These defects can range from minor aesthetic flaws to critical issues that render a garment unwearable. Understanding these defects is the first step toward addressing them effectively.

Categories of Apparel Defects

1. Critical Defects:

- Issues that compromise safety or render the garment unusable.

- Examples: Sharp objects like needles left in the garment, loose trims causing safety hazards.

2. Major Defects:

- Significant flaws that affect the garment’s functionality or aesthetics.

- Examples: Broken zippers, misaligned seams.

3. Minor Defects:

- Small imperfections that don’t affect usability but may influence customer satisfaction.

- Examples: Slight color inconsistencies, minor wrinkles.

By categorizing defects based on severity, businesses can prioritize corrective actions effectively.

Read more: What is Acceptable Quality Level (AQL)

Types of Apparel Defects

Apparel defects can occur at various stages of production. Here’s a detailed look at the most common types:

1. Material Defects

These defects arise from the raw materials used in garment production.

- Color Variations: Uneven dyeing or fading caused by improper fabric treatments.

- Texture Inconsistencies: Rough patches or uneven surfaces due to substandard materials.

- Weaving Flaws: Visible holes, snags, or broken threads in the fabric.

Example: A leading sportswear brand faced backlash when their leggings, made from inferior fabric, showed high rates of pilling after minimal use.

2. Construction Defects

These occur during the assembly and stitching process.

- Seam Issues: Open seams or puckering due to uneven tension.

- Stitching Errors: Skipped, broken, or overlapping stitches that compromise durability.

- Improper Reinforcement: Weak attachment of stress points such as buttons or zippers.

Example: A prominent fashion retailer had to recall thousands of jackets due to loose stitching on pockets, leading to increased operational costs.

3. Measurement Defects

Measurement-related flaws result in ill-fitting garments.

- Size Deviations: Discrepancies from standard sizing charts.

- Pattern Misalignment: Poor alignment of patterns or prints across fabric panels.

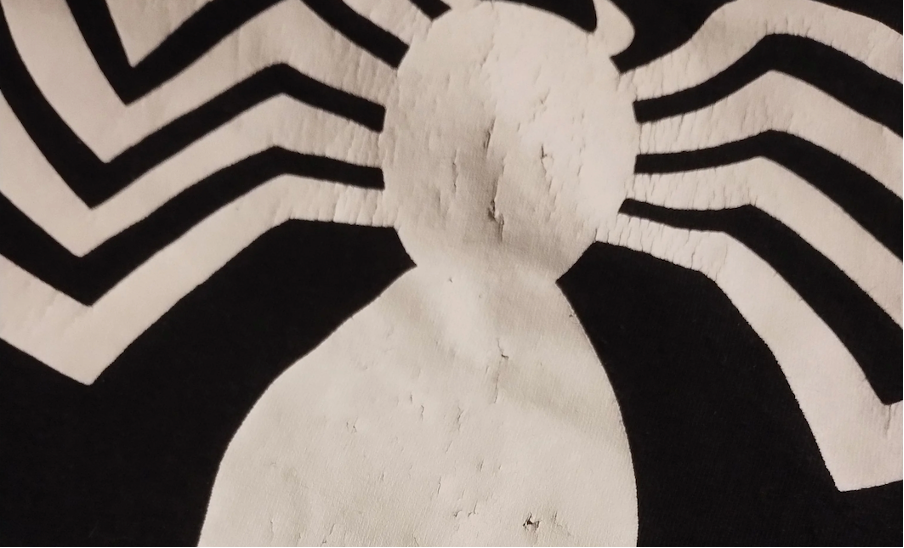

4. Aesthetic Defects

These flaws affect the garment's visual appeal.

- Print Issues: Fading or cracking of printed designs due to low-quality ink or poor application techniques.

- Wrinkles: Improper pressing or storage conditions can cause creases.

- Misplaced Embellishments: Buttons, appliqués, or zippers sewn in the wrong positions.

5. Packaging Defects

Packaging plays a crucial role in shaping customer perception.

- Damaged Packaging: Torn or inadequate wrapping fails to protect garments during transit.

- Incorrect Labels: Mislabeled care instructions or brand tags.

Read more: TOP 10 Common Defects in Garments Quality Inspection

What Causes Apparel Defects?

The root causes of defects vary but often stem from lapses in the production process:

- Low-Quality Raw Materials: Substandard fabrics and trims lead to material flaws.

- Inefficient Machinery: Outdated or poorly maintained equipment causes stitching and cutting errors.

- Lack of Training: Unskilled workers may overlook defects or fail to maintain quality standards.

- Rushed Production: Tight deadlines compromise attention to detail, leading to errors.

- Inadequate Quality Control: A weak inspection process allows defects to pass unnoticed.

Consequences of Apparel Defects

Defective garments can have far-reaching implications:

- Financial Losses: Increased returns, rework, and recalls inflate costs.

- Customer Dissatisfaction: Poor quality leads to negative reviews and reduced repeat business.

- Brand Reputation Damage: Persistent issues can tarnish a brand’s image.

- Regulatory Risks: Non-compliance with safety or quality standards can result in legal penalties.

Case study: A luxury apparel brand faced a public relations crisis after their high-priced jackets were found to have poorly attached buttons, sparking customer outrage.

Solutions to Address Apparel Defects

1. Comprehensive Quality Control

Establish quality checkpoints at every stage of production:

- Pre-Production Inspections: Verify the quality of raw materials and prototypes to prevent large-scale defects.

- During Production Check: Identify construction flaws during assembly.

- Final Inspections: Conduct thorough assessments of finished products.

Read more: How DUPRO Check can drastically improve your production schedule in the garments sector

2. Leverage Technology

Use advanced tools like:

- Automated sewing machines for precise stitching.

- Digital fabric scanners to detect texture inconsistencies.

- AI-driven quality control systems for real-time defect detection.

3. Regular Training Programs

Invest in skill development programs for workers to ensure consistent quality output.

4. Partner with Third-Party Inspection Services

Third-party inspections bring an unbiased perspective and expertise to the apparel quality control process.

Proactive Measures to Prevent Defects

- Supplier Audits: Vet suppliers by conducting supplier audits to ensure they meet quality standards.

- Standardized Documentation: Clearly define specifications for all garments.

- Sampling Plan: Employ tightened level 3 sampling levels as the ISO standards state manufacturing companies should be stable, controlled and verified with a normal level 2 sample plan.

- Feedback Loops: Use customer complaints as insights to improve future production.

- Sustainable Practices: Adopt eco-friendly production methods to align quality with environmental responsibility.

Read more: How to Prevent Garment Defects in Apparel and Textile Industry

Environmental and Ethical Impact of Defective Apparel

Defective garments contribute to the global textile waste problem. Brands that focus on quality not only improve customer satisfaction but also reduce their environmental footprint.

Sustainability Tip: Repurpose defective garments into new products or recycle them to minimize waste.

Why Choose Testcoo?

Apparel defects can pose significant challenges, but they are not insurmountable. By implementing robust apparel quality control measures, leveraging modern technology, and partnering with reliable inspection services like Testcoo, businesses can ensure that their products meet the highest standards of quality.

Testcoo specializes in third-party inspections for the apparel industry, offering:

- Tailored Inspection Checklists: Garment Inspection checklist customized to client specifications.

- Real-Time Reporting: Tech-enabled updates for better decision-making.

- Global Reach: A network of skilled inspectors across production hubs worldwide.

Defect-free garments are not just a mark of excellence—they are a promise to your customers.

Ready to enhance your apparel quality? Contact Testcoo today to learn how we can support your business in delivering impeccable products!

Related Articles

Read MoreFree Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index