Two inspection methods of inspecting fabric on the inspection machine by TESTCOO

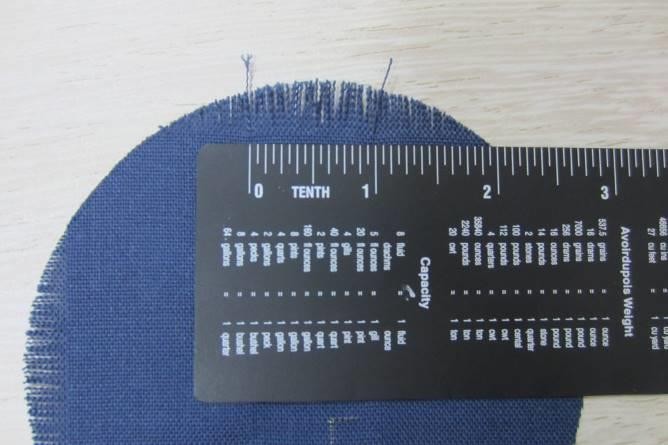

Inspect and grade the selected accordance with the designated point system. Pass the fabric longitudinally through the inspection area.

When inspecting fabric on the inspection machine, there are 2 inspection methods – Type A and Type B of operating the fabric inspection machine.

Type A is keeping the machine stationary when visually checking fabric defects for the length of approximate 0.9~ 1 yard which i same as the height of flat viewing area on the inspection machine. Visually inspect and identify defect wing distance of one meter or yard away. Once the checking for the length is finished, run the machine to the next 0.9 ~ 1 yard, then stop it for the next checking step. Repeat in this way until the checking for the complete roll is finished.

Type B is inspecting fabric at a speed that is compatible with the fabric quality and not exceeding 15 yards per minute. Visually inspect and identify defects from a viewing distance of one meter or yard away while the fabric is in motion. Fabric may be stopped to grade when it is necessary to affirm marginal defects.

If a fabric inspection machine is not available, in the case of inspecting fabric on a flat table with an unrolling perch for rolled fabric or piece folded and stacked fabric, the factory must provide sufficient personnel to assist the inspector to spread the fabric on the table. The inspector stands at one side of the table or the front of the table. If the fabric width is less than 50”, inspector can stand at side. If fabric width over 50”, inspector must stand at the front of table, have the view to cover the full width of fabric. The fabric passes longitudinally through the table, the inspector visually inspects and identifies defects at one side or in the front of fabric for a length of 1 yard fabric, then the fabric helper draws the fabric to the next 1 yard for checking. Repeat in this way until finishing the checking for the complete roll.

The primary goal of these inspection methods is to grade fabric rolls/pieces s “First Quality” or “Second Quality”(also referred to as “A” or “B” Quality).

To cut full width shade bands (6” to 10” length in fabric longitude) from each inspected roll’s beginning and ends during the fabric inspection process for color shading comparison.

Defects appearing outside of cuttable width shall be disregarded. Classify, count and record all defects on the roll data sheet. Mark defects at selvage by chalk.

Color – Check for color shading differences within a dye lot may not vary within a roll/piece (side to side, side center side, or end to end shading) or between rolls/pieces, he shade must match with the approved sample standard(swatch card).

The inspector will use full width bands (6” to 10” length in fabric longitude) to compare shading within a roll, roll to roll, and a roll against approved sample standard.

Contact us at sales@testcoo.com to learn more and get your free sample report.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

Quality Control, Inspection Services in China

Quality Control, Inspection Services in China How Should Traditional Inspection Industry Transit In Industrial 4.0 Era

How Should Traditional Inspection Industry Transit In Industrial 4.0 Era How Do We Make 1+1 More Than 2. Testcoo Knows

How Do We Make 1+1 More Than 2. Testcoo Knows Valentine’s Inspection Knowledge

Valentine’s Inspection Knowledge Starting Your Importing Business From China (Part 1)

Starting Your Importing Business From China (Part 1) Time To Worry About Your Partner Factory

Time To Worry About Your Partner Factory Xiaomi In No Hurry For International Expansion

Xiaomi In No Hurry For International Expansion Critical Rise Imported Car Sales In South Korea

Critical Rise Imported Car Sales In South Korea Boeing is building its first overseas factory in China

Boeing is building its first overseas factory in China “315 Evening Gala”——Savior of China’s Quality Issues

“315 Evening Gala”——Savior of China’s Quality Issues