From Stitching to Soles: Key Quality Checks in Footwear Inspection

The global footwear industry is a dynamic and ever-evolving sector, valued at over $400 billion annually. With rising consumer demands for high-quality and sustainable products, manufacturers and brands are under constant pressure to ensure their footwear meets stringent quality standards. Footwear inspection, therefore, plays a pivotal role in safeguarding product integrity, maintaining brand reputation, and enhancing customer satisfaction. In this blog, we’ll explore the key quality checks involved in footwear inspection, from stitching to soles, and why they’re essential.

The Importance of Footwear Inspection

Footwear is more than just a fashion statement; it’s a functional product that must meet specific performance, safety, and durability requirements. Faulty footwear can lead to customer dissatisfaction, increased returns, and reputational damage. By conducting thorough inspections, manufacturers can identify defects early in the production process, ensure compliance with regulatory standards, and reduce financial losses.

In addition to quality and performance, consumers today are also looking for sustainable and ethical practices in manufacturing. This trend has made inspections critical not only for product quality but also for verifying compliance with environmental and labor standards. Comprehensive inspections allow brands to address these diverse consumer demands while maintaining their competitive edge.

Moreover, defective footwear can pose significant safety hazards, especially in specialized categories like athletic, industrial, and outdoor shoes. Slippery soles, poor stitching, or weak materials can lead to accidents and injuries, further emphasizing the need for rigorous quality checks. This makes a structured inspection process an indispensable part of the production pipeline.

Key Quality Checks in Footwear Inspection

1. Material Quality Check

The first step in ensuring high-quality footwear is evaluating the raw materials. Each material - whether leather, synthetic fabric, rubber, or EVA foam - must meet predefined quality criteria. High-quality materials form the foundation of durable and comfortable footwear.

Inspection Checklist:

- Leather: Check for consistent texture, thickness, and absence of scars or blemishes. Ensure the leather is properly treated to resist cracking or discoloration over time.

- Fabrics: Ensure even dyeing, no loose threads, and adequate tensile strength. Fabrics should also be tested for colorfastness to ensure they do not bleed or fade during use.

- Rubber and Soles: Test for flexibility, durability, and adherence to the design specifications. Rubber should be free from bubbles or cracks that can compromise its integrity.

Why It Matters: The quality of materials directly impacts the durability, appearance, and performance of the footwear. Inferior materials can lead to premature wear and tear, affecting customer satisfaction. Additionally, poor material quality can make footwear susceptible to environmental factors like moisture, heat, or cold, further reducing its lifespan.

Read more: Footwear Quality Control Inspection: Essential Checklist for Shoes

2. Stitching and Seam Strength

Stitching is a critical aesthetic and functional aspect of footwear. Poor stitching not only compromises durability but can also detract from the visual appeal of the product. Strong, even stitching ensures the shoe maintains its shape and withstands regular wear.

Inspection Checklist:

- Inspect for loose, uneven, or skipped stitches.

- Verify the number of stitches per inch (SPI) meets the specifications.

- Perform a seam strength test to ensure seams don’t unravel under stress.

Common Defects:

- Open seams

- Broken or uneven threads

- Overlapping stitches

Testing Methods:

- Manual Inspection: Visually examine the stitching for consistency and strength.

- Mechanical Pull Tests: Apply force to the seams to test their resistance to tearing.

Proper stitching not only extends the shoe’s life but also prevents functional issues like water seepage through open seams. This is especially crucial in outdoor and athletic footwear where performance is paramount.

3. Adhesion Testing

Adhesion quality directly impacts the footwear’s durability. A poorly adhered sole can lead to product failure, affecting both functionality and safety.

Inspection Methods:

- Peel Strength Test: Measure the force required to peel the sole from the upper.

- Heat Resistance Test: Ensure adhesives can withstand varying temperatures without failing.

Common Issues:

- Sole separation

- Visible adhesive marks

- Weak bonding leading to early detachment

Pro Tip: Use advanced adhesives that are both durable and eco-friendly to align with sustainable manufacturing practices.

Adhesion issues often arise due to improper curing or incompatible adhesive types. Manufacturers should ensure their bonding materials are suitable for the footwear’s intended use and environmental exposure.

4. Outsole and Midsole Quality

The outsole and midsole are critical components affecting footwear performance, grip, and comfort. These parts endure the most wear and tear and must meet stringent standards for longevity and performance.

Inspection Checklist:

- Check for cracks, warping, or uneven surfaces.

- Verify that the tread patterns are consistent and effective for the intended use.

- Test the cushioning properties of midsoles for impact absorption and comfort.

Tests to Perform:

- Abrasion Resistance Test: Evaluate the outsole’s ability to withstand friction and wear.

- Slip Resistance Test: Ensure the sole provides adequate grip on various surfaces.

- Flexing Endurance Test: Test the shoe’s ability to endure repeated bending without cracking.

Why It Matters: A poorly constructed outsole can lead to safety hazards, while inadequate midsoles can cause discomfort, reducing the shoe’s overall usability. Additionally, specialized footwear like hiking boots or sports shoes requires superior grip and durability to perform effectively in challenging conditions.

5. Fit and Comfort Assessment

Ensuring the footwear fits well and provides adequate comfort is essential for customer satisfaction. A well-fitting shoe not only enhances comfort but also prevents injuries such as blisters or arch pain.

Inspection Process:

- Perform a size fitting test using standardized measuring tools.

- Assess the comfort level by evaluating padding, arch support, and insole quality.

- Check for sharp edges or protrusions that could cause discomfort.

Common Complaints:

- Inconsistent sizing

- Insufficient arch support

- Rough interior surfaces

Testing Tips:

- Use wear-testers to gather real-world feedback on comfort and fit.

- Incorporate biomechanical testing to evaluate how the shoe performs under actual movement conditions.

Fit issues are one of the most common reasons for returns in the footwear industry. Addressing these during production can significantly reduce return rates and improve customer loyalty.

6. Aesthetic Inspection

Appearance matters, especially in fashion and casual footwear. The visual appeal of a shoe can significantly influence a buyer’s decision.

Inspection Points:

- Ensure uniformity in color and pattern across pairs.

- Verify logo placement and branding are accurate.

- Check for blemishes, scratches, or other cosmetic defects.

Common Issues:

- Mismatched colors

- Misaligned logos

- Visible glue marks

Pro Tip: Use automated visual inspection systems to detect subtle aesthetic flaws that may be missed during manual checks. This not only improves efficiency but also ensures consistency across large production batches.

Read more about List of Defects during Visual Inspection in Footwear Quality Control

7. Performance Testing

Footwear must perform as intended, whether it’s for running, hiking, or formal occasions. Performance testing ensures the shoe’s functionality aligns with its intended purpose.

Key Performance Tests:

- Flex Testing: Measure the shoe’s ability to endure repeated flexing.

- Water Resistance Test: For waterproof footwear, ensure no water seepage.

- Compression and Impact Testing: Verify durability under heavy loads.

- Thermal Testing: Assess the shoe’s performance under extreme temperatures.

Why It Matters: Performance tests validate that the footwear can withstand real-world conditions, ensuring customer safety and satisfaction. These tests are particularly important for athletic or work-related footwear, where failure could lead to injuries.

8. Packaging and Labeling Inspection

The final step in the inspection process is to verify packaging and labeling, ensuring compliance with branding and regulatory requirements.

Checklist:

- Confirm accurate product labeling (e.g., size, material composition).

- Ensure protective packaging prevents damage during transit.

- Verify barcodes and tags are correctly applied.

Additional Tips:

- Use eco-friendly packaging to align with sustainability goals.

- Test packaging durability to ensure it protects the product during shipping.

Proper packaging not only protects the footwear but also contributes to the brand’s image. Premium packaging can enhance the unboxing experience, adding value for the customer.

Read more: What Is ASTM-F2413-18? Protective Footwear Standard

Why Choose Third-Party Inspections?

Many manufacturers and brands rely on third-party inspection companies to ensure consistent quality and impartial evaluations. Third-party inspectors bring:

- Expertise: Comprehensive knowledge of industry standards and regulations.

- Unbiased Assessments: Objective evaluations free from internal pressures.

- Cost Savings: Early defect detection reduces returns and rework costs.

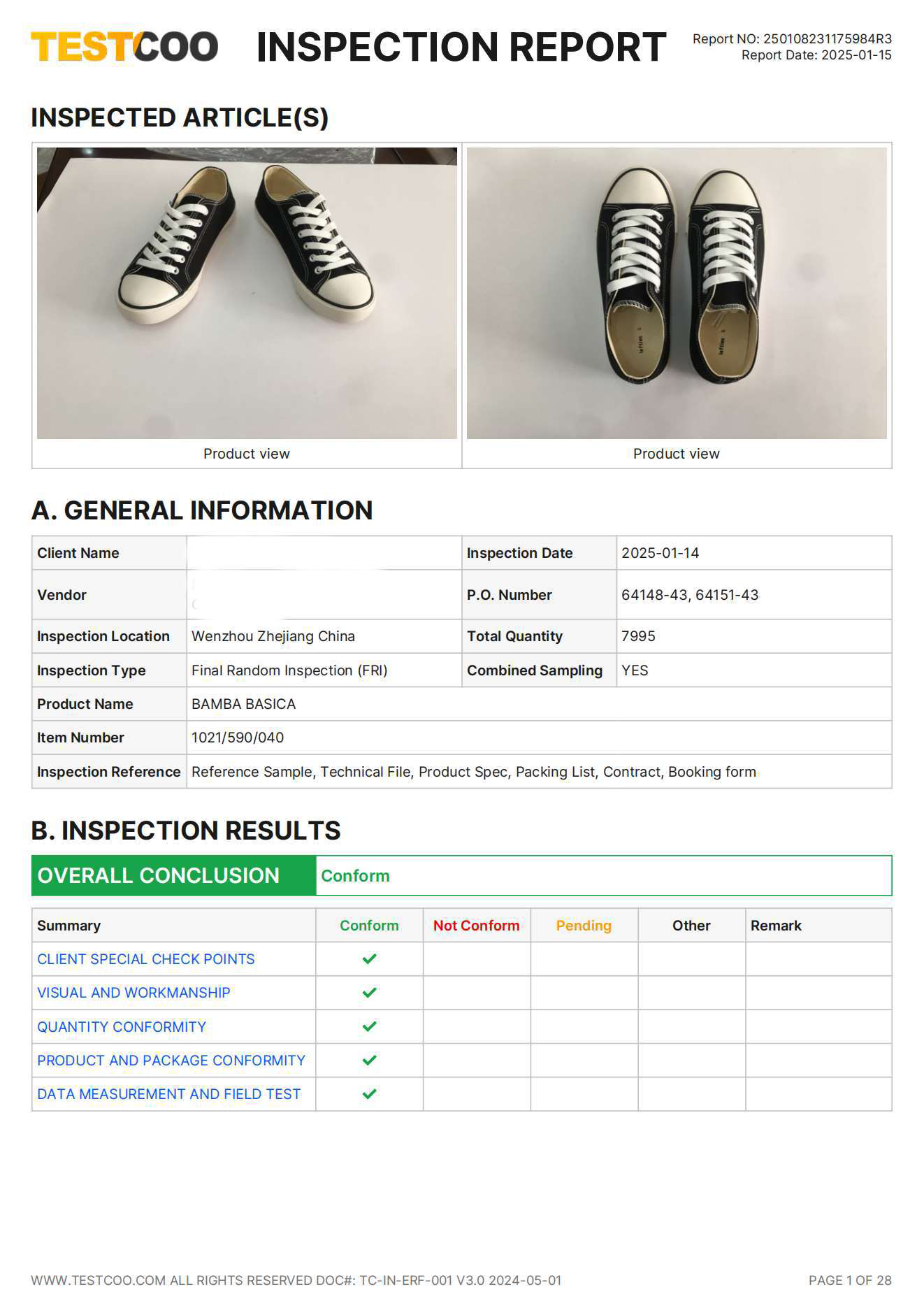

Download a Free Sample Report of Footwear Inspection

DOWNLOAD NOW

Choosing Testcoo as your Third-Party Footwear Inspection Service Provider

Selecting the right footwear inspection service provider is a crucial decision for manufacturers and retailers alike. A reliable inspection partner can significantly impact the quality of footwear produced, making it essential to evaluate potential providers carefully. One of the first considerations when choosing an inspection service is the provider's experience and expertise in the footwear industry. Companies with a proven track record in footwear inspections are more likely to understand the specific quality standards required by different markets.

Another critical factor to consider is the range of services offered by the inspection provider. Some companies may specialize in specific types of inspections, while others may offer a comprehensive suite of services, including initial production, during production, and final random inspections. Depending on the needs of the manufacturer or retailer, it may be beneficial to partner with a provider that can accommodate various inspection stages throughout the production process. Flexibility and adaptability in service offerings are essential for addressing the unique challenges that may arise during footwear manufacturing.

By carefully considering these factors, manufacturers and retailers can choose a footwear inspection service provider that aligns with their quality goals and helps ensure that their products meet the highest standards.

Footwear manufacturers must choose Testcoo for reliable, efficient, and comprehensive quality control solutions. With a global network of expert inspectors, Testcoo ensures your products meet international standards and customer expectations. Our tailored inspection services, including initial production, during production, and final random inspections, identify and eliminate defects at every stage. By choosing Testcoo, manufacturers can prevent costly errors, protect brand reputation, and streamline their supply chain operations. We provide detailed, actionable reports within 24 hours, allowing for timely decision-making. Trust Testcoo as your quality assurance partner to deliver defect-free garments and build long-term customer satisfaction.

Want Us To Ensure Your Product Quality?

Request a demo to see our report details to know more. Worth to contact us to get reliable, efficient and comprehensive quality control services. We will arrange an inspection for you, anytime, any where.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index