From Factory Audit to Final Inspection: Building Reliable Supply Chains in Indonesia

Indonesia offers a strategic manufacturing base defined by a workforce of over 270 million and direct access to major Indian and Pacific Ocean shipping lanes. Government infrastructure investments and foreign incentives have accelerated industrial growth across the electronics, textile and automotive sectors. This combination of labor availability and logistical connectivity positions the country as a primary hub for global production capacity.

Rapid industrial expansion necessitates rigorous supply chain oversight to ensure reliability. Implementing structured quality control through factory audits and final random inspections is essential for mitigating risks such as product recalls and brand damage. Adhering to these protocols allows companies to meet international standards while minimizing costs and securing long-term operational stability.

Why Is Indonesia a Strategic Manufacturing Hub for Global Buyers?

Strategic Labor Advantages

Indonesia possesses a decisive demographic advantage with a median age of 30, offering a young and scalable workforce. Wages in the manufacturing sector remain highly competitive compared to developed economies. Electronics manufacturers, specifically, benefit from labor costs that are a fraction of those in South Korea or Japan, allowing for significant reductions in production overhead. Government-led vocational training complements this cost efficiency. Programs focused on advanced electronics assembly, textile techniques and automotive production ensure the w orkforce possesses the technical skills necessary to meet modern industrial standards.

Industrial Sector Diversification

The manufacturing landscape spans both established and developing industries. Textile producers leverage proximity to raw materials like cotton and polyester to supply global fashion brands with cost-competitive fabrics.The automotive sector has expanded beyond domestic needs, with manufacturers exporting vehicles and components to regional markets. Simultaneously, multinational electronics companies utilize government tax incentives and industrial land grants to scale production of consumer goods ranging from smartphones to home appliances.

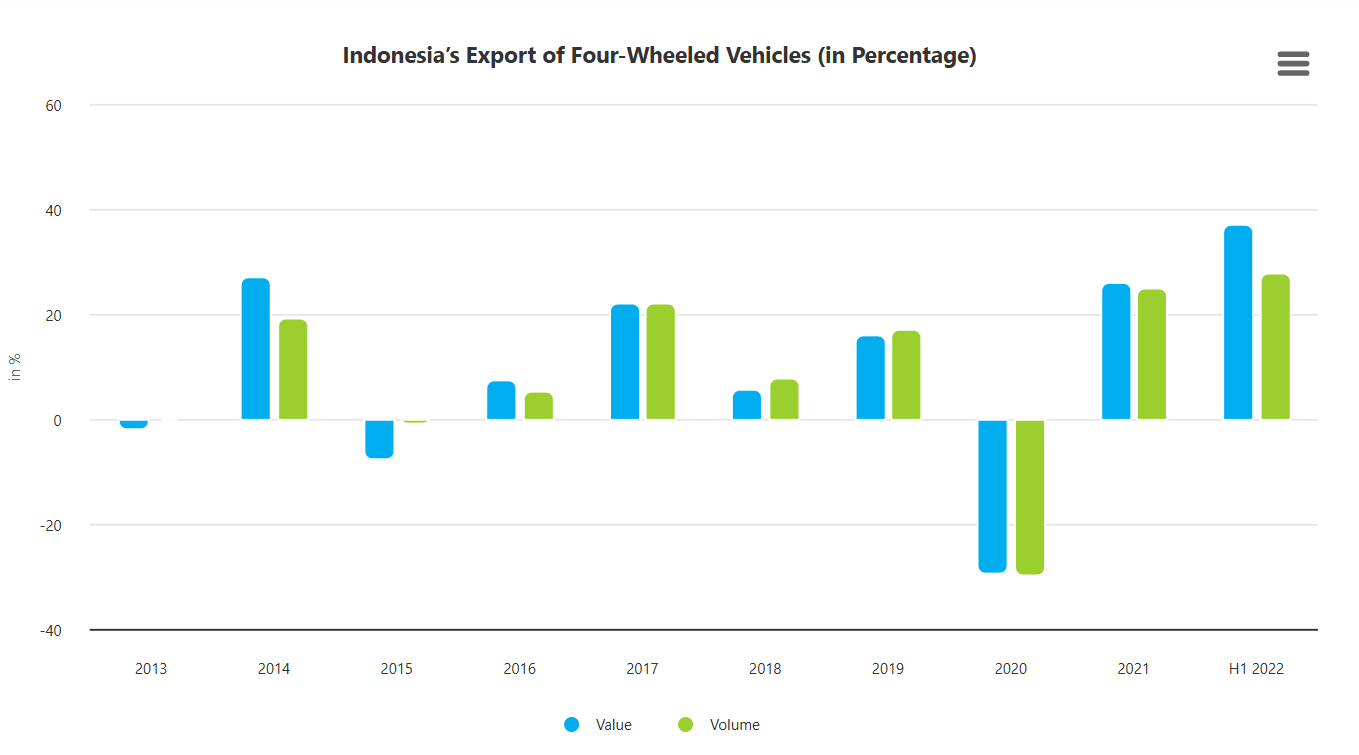

Export Growth and Market Access

Steady export growth correlates directly with expanding manufacturing capabilities and robust trade relations. Indonesia utilizes Free Trade Agreements with the EU, Japan and ASEAN members to eliminate trade barriers. The ASEAN-Australia-New Zealand Free Trade Agreement allows Indonesian textiles and furniture to enter Oceanian markets with reduced or zero tariffs. These regulatory advantages significantly enhance the price competitiveness of Indonesian products, attracting international buyers seeking long-term value.

Regional Supply Chain Integration

Indonesia functions as a critical node within the Southeast Asian supply chain, benefiting from proximity to manufacturing hubs like Vietnam, Malaysia and Thailand. This geographic advantage facilitates cross-border production integration. Electronics companies often source specialized components from Malaysia while utilizing Thai logistics networks for broader distribution. Infrastructure investments, such as the Jakarta-Bandung High-Speed Railway, strengthen domestic connectivity and regional transportation links, improving the overall efficiency of moving goods to market.

What Is a Factory Audit and Why Is It Critical in Indonesia?

Factory audits systematically evaluate manufacturing operations and regulatory compliance. In Indonesia, these assessments categorize into specific focus areas to address distinct risks within the supply chain.

Social Compliance Audit

Social Compliance Audit verify adherence to labor laws and ethical standards. Auditors examine working conditions to ensure facilities provide necessary safety equipment and conduct regular employee training. In the labor-intensive garment sector, strict monitoring of working hours confirms compliance with Indonesia's standard 40-hour workweek and mandates legal compensation for overtime. These evaluations also scrutinize anti-discrimination policies to ensure equal opportunity regardless of gender, race, or religion. Verifying these practices protects brand reputation and confirms that suppliers operate ethically.

Quality System Audits

Quality system audits assess the robustness of internal management processes. Electronics manufacturers must demonstrate adherence to rigorous testing protocols during these evaluations. Auditors verify that components undergo functionality and durability testing before assembly to meet International Electrotechnical Commission (IEC) standards. Beyond physical testing, the audit reviews documentation and record-keeping accuracy. Maintaining precise logs of raw material sourcing and production metrics ensures traceability, allowing manufacturers to quickly pinpoint the root cause of any quality deviation.

Production Capacity Audits

Production capacity audits determine a facility's ability to meet volume demands. Buyers sourcing automotive parts rely on these assessments to quantify production lines, process efficiency and skilled labor availability. Analyzing these factors confirms whether a factory can fulfill large orders within specific timeframes. Auditors also review expansion plans to gauge scalability, ensuring the supplier can adapt to fluctuating market requirements. Establishing this baseline prevents supply disruptions and secures a steady flow of goods.

Risk Mitigation and Strategic Compliance

Systematic auditing provides early risk identification within the Indonesian market. Evaluating operations prior to establishing long-term contracts highlights potential regulatory non-compliance or quality control gaps. This proactive approach mitigates legal liabilities and protects brand equity while ensuring suppliers adhere to global sustainability and ethical benchmarks.

Read More: Southeast Asia’s Booming Industries and the Growing Need

How Do Factory Audits Help Buyers Reduce Supply Chain Risks?

Factory audits play a pivotal role in helping buyers mitigate supply chain risks in Indonesia.

Identifying Compliance Risks

In Indonesia, regulatory compliance can be complex, with a range of laws and international standards to adhere to. For example, in the food and beverage industry, factories must comply with strict health and safety regulations. A factory audit can identify potential non - compliance issues early on. If a factory is not following proper food handling and storage procedures, as required by Indonesian health regulations, it could lead to product contamination. This not only poses a risk to consumer health but also exposes the buyer to legal liabilities and a damaged brand reputation. By conducting regular audits, buyers can ensure that their suppliers are meeting all legal requirements, reducing the likelihood of costly recalls and legal battles.

Evaluating Production Capacity and Delivery Reliability

A production capacity audit helps buyers understand whether a factory can meet their order volumes. Suppose a clothing brand plans to place a large order for summer apparel with an Indonesian factory. Through a production capacity audit, the brand can assess if the factory has enough sewing machines, skilled workers and raw material supplies to complete the order within the required time frame. If the factory's production capacity is overestimated, it could result in delivery delays. In the fast - paced fashion industry, such delays can mean missing the prime selling season, leading to lost sales and dissatisfied customers. By accurately evaluating production capacity during the audit, buyers can make informed decisions and avoid supply chain disruptions due to production bottlenecks.

Ensuring Quality Consistency

Quality system audits are essential for maintaining quality consistency. In the electronics industry in Indonesia, for instance, a buyer may source smartphones from a local factory. A quality system audit will check if the factory has a robust quality control process in place. This includes verifying that the factory conducts regular component testing, such as battery life tests and screen durability tests. If the factory does not have proper quality control measures, the smartphones may have high defect rates. These defective products can lead to customer returns, negative reviews and a loss of customer trust. Through audits, buyers can ensure that the factory follows consistent quality standards, leading to higher - quality products and a more reliable supply chain.

Read More: Halal Certification Inspection in Indonesia & Malaysia | Testcoo

Frequently Asked Questions (FAQs)

1.Why are factory audits important when sourcing from Indonesia?

Factory audits help buyers assess supplier capability, compliance and operational risks before production begins. In Indonesia, where manufacturing standards can vary widely by region and factory size, audits provide critical insight into labor practices, quality systems and production capacity.

2. What types of inspections are commonly used during production in Indonesia?

Buyers typically use a combination of initial production checks, during production inspections and final random inspections. This structured approach helps identify quality issues early, control production consistency and ensure products meet specifications before shipment.

3. How do factory audits and final inspections work together to reduce supply chain risk?

Factory audits evaluate whether a supplier can meet quality and compliance expectations, while final inspections verify that finished goods match approved standards. Together, they create a closed loop quality control process that minimizes delays, defects and costly rework.

4. What challenges do overseas buyers face when managing quality control in Indonesia?

Common challenges include limited on site visibility, communication gaps, inconsistent quality management systems and differences in regulatory understanding. Third party inspections and audits help bridge these gaps by providing independent verification and local expertise.

5. How can third party quality services support long term supply chain reliability in Indonesia?

Third party providers offer standardized audit processes, trained local inspectors and transparent reporting. By combining audits, production monitoring and final inspections, buyers gain better control over quality outcomes and build more stable, long term supplier relationships.

↵

Why Choose a Professional QC Partner for Indonesia Supply Chains?

The Strategic Value of Professional QC Partners

Successfully managing Indonesian supply chains requires specialized local expertise. Professional quality control (QC) partners provide the necessary technical resources and regulatory knowledge to navigate this manufacturing environment effectively.

Regulatory Expertise and Compliance

Professional partners possess comprehensive knowledge of local statutes and industry benchmarks. In the food processing sector, auditors apply the Indonesian National Standard (SNI) to verify safety protocols, including pesticide residue limits and hygiene requirements. This specific regulatory insight ensures audits and inspections guarantee full compliance, preventing the costly legal exposure associated with misinterpreting local laws.

Leveraging Local Networks

Established partners utilize extensive connections with suppliers, industry associations and regulatory bodies to monitor emerging trends. When audits reveal production failures, these networks allow the QC firm to immediately recommend verified alternative suppliers or implementation strategies based on local best practices. Accessing these relationships accelerates problem resolution and minimizes supply chain disruption.

Long-Term Cost Efficiency

Engaging a professional partner reduces operational costs by minimizing defects and rework. Final random inspections identify minor quality variations early, preventing the escalation into expensive product recalls or replacements. Furthermore, efficient audit protocols streamline the supply chain to reduce delay-related expenses. Securing quality assurance at the source safeguards financial performance and maintains market competitiveness.

Brand Reputation Protection

Outsourcing QC safeguards brand equity in a consumer-aware market. Defective products sourced from Indonesia can immediately degrade consumer trust and erode market share. Professional partners enforce strict inspection processes to ensure all exports meet global quality expectations. This rigor maintains brand integrity and protects the company's long-term investment in its reputation.

How Can Businesses Build Reliable Supply Chains in Indonesia Through End to End Quality Control?

Establishing a robust supply chain in Indonesia demands the integration of comprehensive factory audits and rigorous final random inspections. Audits focused on social responsibility, quality systems and production capacity function as the primary mechanism for ensuring ethical operations and manufacturing capability. Identifying potential risks at this foundational stage significantly reduces the probability of downstream disruptions. Final random inspections subsequently serve as the definitive quality verification, guaranteeing that exports remain free from defects before shipment. This dual strategy safeguards business interests and promotes long-term operational sustainability.

Navigating Indonesia's regulatory and logistical environment necessitates professional expertise. Testcoo utilizes deep knowledge of local standards and broad industry networks to resolve compliance challenges efficiently. Delivering thorough auditing and detailed inspection services enables businesses to secure and maintain high-performing supply chains within the region.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index