The Rising Demand for Smartphone and EV Battery Testing in Vietnam and Thailand

The Growth of Local Manufacturing

In recent years, Vietnam and Thailand have witnessed a remarkable upsurge in their local manufacturing sectors. This growth is driven by multiple factors, including favorable government policies, a large and relatively inexpensive labor force, and strategic geographical locations that facilitate trade.

Vietnam, in particular, has become an attractive destination for manufacturing investments. With a population of over 100 million, it offers a vast labor pool. The government has been proactive in promoting manufacturing through various incentives, such as tax breaks and streamlined administrative procedures. As a result, the country has seen a significant influx of foreign direct investment (FDI) in the manufacturing domain.

Thailand, on the other hand, has a well-established manufacturing base, especially in the automotive and electronics industries. The Thai government's long-term industrial development plans have laid a solid foundation for the growth of manufacturing. It has a relatively developed infrastructure, skilled workforce, and a business-friendly environment that encourages both domestic and foreign investments.

Within this growing manufacturing landscape, the production of smartphones and electric vehicle (EV) batteries has emerged as a crucial and rapidly expanding segment.

The smartphone industry in both countries has been booming. Vietnam has become a major hub for smartphone assembly. Many global smartphone manufacturers have set up production facilities in Vietnam to take advantage of its cost-effective production environment. For example, Samsung has a large-scale manufacturing plant in Vietnam, which not only assembles smartphones but also contributes to the development of the local supply chain. The production of smartphones in Vietnam has not only met the domestic demand but has also significantly contributed to the country's exports.

In Thailand, the smartphone market is also growing steadily. Local manufacturing is complemented by a strong distribution and retail network, making smartphones more accessible to the local population. Moreover, the growth of the smartphone industry in Thailand has spurred the development of related industries, such as mobile applications and accessories.

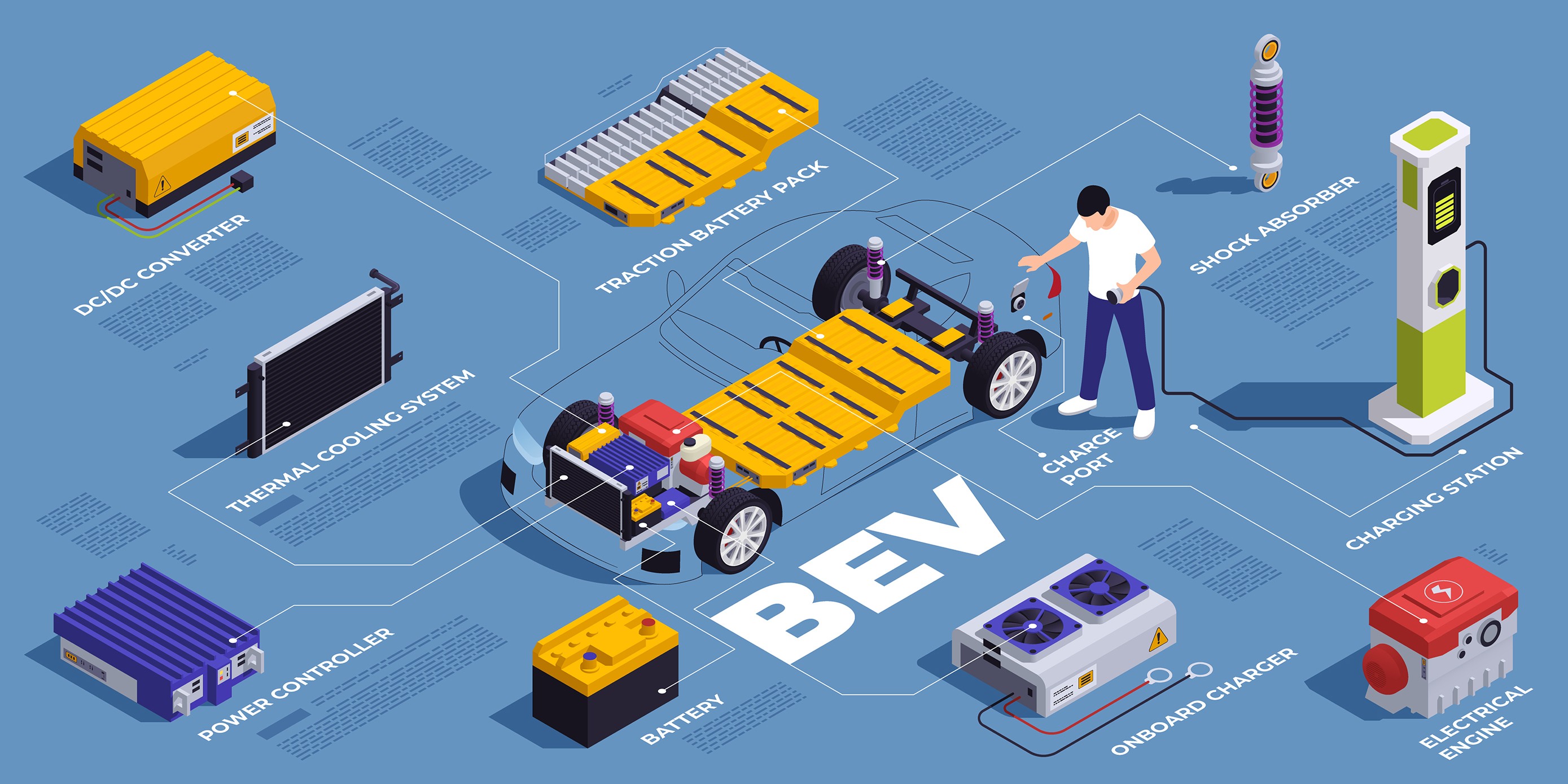

The EV battery production is another area of focus. With the global shift towards electric vehicles, the demand for EV batteries has been skyrocketing. Vietnam and Thailand are positioning themselves as key players in this emerging market.

In Vietnam, several domestic and international companies are investing in EV battery production. The government's support for the development of clean energy technologies has created a conducive environment for the growth of the EV battery industry. These investments are not only aimed at meeting the future demand for electric vehicles in Vietnam but also at tapping into the global market.

Thailand has also been actively promoting the development of its EV battery industry as part of its broader strategy to transform its automotive industry towards electric mobility. The Thai government has introduced a series of incentives to attract investments in EV battery manufacturing, research, and development. This includes tax incentives, land allocation for manufacturing facilities, and support for R&D activities. As a result, some major international players have shown interest in establishing EV battery production facilities in Thailand.

Quality and Safety Inspections: A Must

1. Importance in the Smartphone Industry

In the highly competitive smartphone industry, quality and safety inspections are of paramount importance. For users, a high-quality smartphone ensures a seamless and enjoyable experience. A device that has undergone rigorous quality checks is less likely to have issues such as sudden freezes, unresponsive touchscreens, or frequent software glitches. For example, a smartphone with a well-tested battery will not only provide consistent power but also avoid potential hazards like overheating or swelling, which could otherwise lead to damage to the device or even pose a safety risk to the user.

From a brand's perspective, maintaining high-quality standards through inspections is crucial for building and maintaining a positive brand reputation. In today's digital age, where consumers can easily share their experiences online, a single negative incident related to a smartphone's quality or safety can spread like wildfire and severely damage a brand's image. For instance, if a particular model of smartphone is found to have a defective component after it has been released to the market, it can lead to a significant number of customer complaints, negative reviews, and ultimately, a loss of market share. Brands that prioritize quality and safety inspections are more likely to gain the trust of consumers, leading to increased customer loyalty and repeat purchases.

2. Significance for EV Batteries

The safety of electric vehicle (EV) batteries is not just a matter of product quality; it is a matter of life and death. EV batteries store a large amount of electrical energy in a relatively small space, and if not properly designed, manufactured, and tested, they can pose serious risks. Lithium-ion batteries, which are commonly used in EVs, can experience thermal runaway under certain conditions. This can occur due to overcharging, over-discharging, short circuits, or physical damage. When thermal runaway happens, the battery can heat up rapidly, leading to fires or even explosions. Such incidents not only put the lives of the vehicle occupants at risk but also cause significant damage to property.

Moreover, the safety and quality of EV batteries are critical for the long-term development of the electric vehicle industry. As the adoption of electric vehicles continues to grow, any safety-related issues with EV batteries can create widespread public concern and hesitation among potential buyers. To build consumer confidence in electric vehicles, it is essential that EV batteries meet the highest safety and quality standards. Stringent safety inspections can help identify potential issues early in the manufacturing process, allowing manufacturers to make necessary improvements and ensure that only safe and reliable batteries reach the market. This, in turn, promotes the growth and sustainability of the EV industry, contributing to a cleaner and more sustainable transportation future.

Lithium-Ion Batteries: Key Players

1. Structure and Working Principle

Lithium-ion batteries, the workhorses of modern portable electronics and electric vehicles, have a relatively complex yet fascinating structure and working mechanism. Structurally, a lithium-ion battery consists of several key components: the positive electrode (cathode), negative electrode (anode), electrolyte, and separator.

The cathode is typically made of a lithium-containing compound, such as lithium cobalt oxide, lithium iron phosphate, or nickel-cobalt-manganese (NCM) ternary materials. These materials are responsible for providing the lithium ions during the charge-discharge process. The anode, on the other hand, is commonly composed of graphite. Graphite has a layered structure that can easily accommodate lithium ions.

The electrolyte is a crucial component that enables the movement of lithium ions between the cathode and the anode. It is usually a lithium-salt-based solution in an organic solvent. The separator is a thin, porous membrane that physically separates the cathode and the anode, preventing direct contact and short circuits while allowing the passage of lithium ions.

During charging, an external power source forces lithium ions to move from the cathode to the anode. As the lithium ions move through the electrolyte and reach the anode, they intercalate (insert) into the graphite layers. At the same time, electrons flow through an external circuit from the cathode to the anode to maintain electrical neutrality. This process stores energy in the battery.

When discharging, the process is reversed. Lithium ions move from the anode back to the cathode through the electrolyte. The electrons flow back through the external circuit in the opposite direction, creating an electric current that can be used to power devices. For example, in a smartphone, this current powers the various components such as the display, processor, and sensors, while in an electric vehicle, it drives the electric motor

Read more about how lithium -ion batteries work.

2. Safety Concerns and Testing Focus

Despite their widespread use and numerous advantages, lithium-ion batteries are not without safety concerns. One of the most critical issues is the risk of thermal runaway. Thermal runaway occurs when a battery experiences an uncontrolled increase in temperature, which can lead to a chain reaction of exothermic (heat-releasing) chemical reactions within the battery. This can be triggered by various factors, including overcharging, over - discharging, physical damage (such as punctures or impacts), and manufacturing defects.

Overcharging can cause the lithium ions to build up too quickly in the anode, leading to the formation of lithium metal deposits, also known as lithium dendrites. These dendrites can grow over time and eventually pierce the separator, causing a short circuit within the battery. A short circuit can then lead to a rapid increase in temperature, potentially triggering thermal runaway.

Over - discharging, on the other hand, can cause the battery to reach a state where the electrodes' chemical structures are damaged, making the battery more prone to failure and safety issues. Physical damage to the battery, such as being dropped or crushed, can also rupture the separator or damage the electrodes, leading to internal short - circuits and thermal runaway.

Manufacturing defects, such as inconsistent electrode coatings, impurities in the electrolyte, or improper assembly, can also create weak points in the battery that may lead to safety problems. For example, if the electrolyte contains impurities, it may cause unwanted chemical reactions that can increase the temperature and pressure inside the battery.

Given these safety concerns, testing lithium-ion batteries is of utmost importance. Testing focuses on several key areas. Thermal stability testing is crucial to evaluate a battery's behavior under high-temperature conditions and its resistance to thermal runaway. This involves subjecting the battery to various temperature profiles and monitoring its performance, such as changes in voltage, current, and temperature over time.

Electrical safety testing ensures that the battery can handle normal charging and discharging operations without issues such as overcharging or over-discharging. This includes testing the battery's charging and discharging limits, as well as its response to abnormal electrical conditions, such as short circuits or overvoltage situations.

Mechanical safety testing assesses the battery's ability to withstand physical stress. This may involve drop tests, impact tests, and vibration tests to simulate real - world scenarios where the battery may be subjected to physical damage. By thoroughly testing lithium-ion batteries in these areas, manufacturers can identify potential safety risks early in the production process and take appropriate measures to improve the battery's safety and reliability.

At Testcoo, we offer comprehensive testing services for lithium-ion batteries used in smartphones and EVs. Our state-of-the-art testing facilities and experienced team of professionals can conduct a wide range of tests, including those for thermal stability, electrical safety, and mechanical integrity. We understand the importance of ensuring the safety and quality of these batteries, and our services are designed to help manufacturers meet the highest industry standards. Whether you are a smartphone manufacturer looking to ensure the reliability of your device's battery or an EV battery producer aiming to enhance the safety of your products, Testcoo can provide the testing solutions you need. Contact us today to learn more about how we can assist you in ensuring the quality and safety of your lithium-ion batteries.

Market Overview in Vietnam and Thailand

1. Vietnam's Market

Vietnam's smartphone market has been on an upward trajectory in recent years. The increasing affordability of smartphones, driven by local manufacturing and intense competition among brands, has led to a significant rise in smartphone penetration. With a young and tech-savvy population, the demand for smartphones with advanced features such as high-quality cameras, large displays, and long-lasting batteries is growing.

In terms of market size, Vietnam's smartphone market has seen robust growth. The market is highly competitive, with global players like Samsung, Apple, and a host of Chinese brands vying for market share. Samsung, in particular, has a strong presence in Vietnam, leveraging its manufacturing facilities in the country to offer a wide range of smartphones at different price points.

The electric vehicle (EV) market in Vietnam is also emerging. Although currently in its nascent stage, the government's push for sustainable transportation and incentives for EV adoption are fueling growth. As of 2024, there are a few domestic EV manufacturers starting to make their mark, and international players are also showing interest in entering the market.

This growth in the EV market has, in turn, spurred the demand for EV battery testing. With local manufacturing of EV batteries beginning to take shape, ensuring the quality and safety of these batteries is crucial. The demand for battery testing services is expected to grow in tandem with the expansion of the EV battery manufacturing industry in Vietnam.

2. Thailand's Market

Thailand‘s smartphone market has a different growth pattern compared to Vietnam. After experiencing a decline in previous years due to economic slowdowns and reduced consumer purchasing power, the market is showing signs of recovery. According to IDC, the smartphone market in Thailand is expected to grow by 17.1% in 2024, with shipments reaching 16.9 million units.

The market is characterized by a diverse range of price segments. The entry-level smartphone segment (below $200) holds a significant market share, accounting for 56.9% in 2024, up from 54.8% the previous year. This is due to the large number of price-sensitive consumers in Thailand. However, the high-end market has seen a decline in market share, from 12% to 9%. Brands like Samsung and Apple remain popular in the Thai market, with Samsung leading in terms of overall market share, especially with its mid-range and high-end Galaxy series.

In the EV sector, Thailand has a more established automotive industry compared to Vietnam, which gives it an edge in the development of electric vehicles. The Thai government has been actively promoting the adoption of electric vehicles through various policies, such as tax incentives for EV purchases and the development of EV charging infrastructure. As a result, the local manufacturing of EVs and EV batteries is progressing steadily.

Major international automotive companies are setting up EV production facilities in Thailand, which has led to a growing need for EV battery testing. The Thai market for EV battery testing is more developed in terms of infrastructure and industry awareness compared to Vietnam, but both countries are seeing an increase in demand for these services as their respective EV industries grow.

In summary, while both Vietnam and Thailand are witnessing growth in the smartphone and EV battery manufacturing sectors, the market dynamics in each country are unique. Vietnam's smartphone market growth is driven by its large and young population, along with cost - effective manufacturing, while Thailand's market recovery is influenced by a combination of economic factors and brand strategies. In the EV battery market, Thailand's more established automotive industry gives it a head start in terms of development, but Vietnam is catching up fast, and both countries are increasingly recognizing the importance of quality and safety inspections in these sectors.

Testcoo: Your Ideal Partner

1. Our Comprehensive Testing Services

At Testcoo, we pride ourselves on offering a wide-ranging suite of testing services tailored specifically to smartphones and EV batteries.

For smartphones, our testing portfolio covers every aspect of the device. We conduct thorough physical inspections, examining the build quality, materials used, and the precision of component assembly. Our team checks for any signs of flaws, such as uneven seams, loose buttons, or misaligned ports. The display is rigorously tested for color accuracy, brightness levels, contrast ratios, and touch sensitivity. We use advanced equipment to measure these parameters accurately, ensuring that the display provides an optimal viewing and interaction experience.

Functionality testing is another crucial area. We test all the features of a smartphone, from basic functions like calling, texting, and internet browsing to more advanced capabilities such as camera performance, fingerprint sensor accuracy, and wireless connectivity (Wi-Fi, Bluetooth, NFC). Our camera testing includes evaluating image quality in different lighting conditions, autofocus speed, and the functionality of various shooting modes.

When it comes to EV batteries, we offer a comprehensive set of tests to ensure their safety, performance, and reliability. Our thermal stability tests simulate extreme temperature conditions that the battery may encounter during operation or storage. We monitor the battery's temperature, voltage, and current responses to identify any potential thermal runaway risks.

Electrical performance testing involves assessing the battery's charging and discharging efficiency, capacity retention over cycles, and its ability to handle different load demands. We also conduct mechanical integrity tests, such as vibration, shock, and drop tests, to ensure that the battery can withstand the rigors of real-world usage in an electric vehicle.

2. Why Choose Testcoo

There are several compelling reasons to choose Testcoo as your testing partner.

Our team consists of highly trained and experienced professionals. Our engineers and technicians have in-depth knowledge of the latest smartphone and EV battery technologies. They stay updated with the industry's best practices and regulatory requirements, allowing us to provide accurate and reliable testing results. For example, our battery testing experts are well-versed in the latest standards for lithium-ion batteries, such as those set by international organizations like the International Electrotechnical Commission (IEC).

We are equipped with state of the art testing facilities and advanced equipment. Our laboratories are outfitted with high-precision instruments that can measure even the slightest variations in battery performance or smartphone functionality. This enables us to conduct detailed and accurate tests, providing you with comprehensive data about your products.

With years of experience in the testing industry, we have built a strong reputation for delivering high-quality services. We have worked with numerous clients, from emerging startups to well-established multinational corporations. Our long-standing relationships with these clients are a testament to our commitment to quality, reliability, and customer satisfaction.

Moreover, we understand the importance of timely delivery. In the fast-paced smartphone and EV industries, time-to-market is crucial. We strive to complete our testing processes efficiently without compromising on quality, ensuring that you can bring your products to market on schedule. Whether you need to meet a product launch deadline or comply with regulatory requirements, Testcoo is your reliable partner for all your smartphone and EV battery testing needs. Contact us today to learn more about how we can support your business's quality assurance efforts.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index