How to Read AQL Table?

What Does AQL Mean?

‘AQL‘ stands for ‘Acceptance Quality Limit‘, and is defined as the “quality level that is the worst tolerable” in ISO 2859-1. It represents the maximum number of defective units, beyond which a batch is rejected. Importers usually set different AQLs for critical, major, and minor defects. Most Asian exporters are familiar with this type of setting.

For example: “AQL is 1.5%” means “I want no more than 1.5% defective items in the whole order quantity, on average over several production runs with that supplier”.

They help determine two key elements

1. How many samples should be picked and inspected, among a batch of product or parts?

2. Where is the limit between acceptability and refusal, when it comes to defective products?

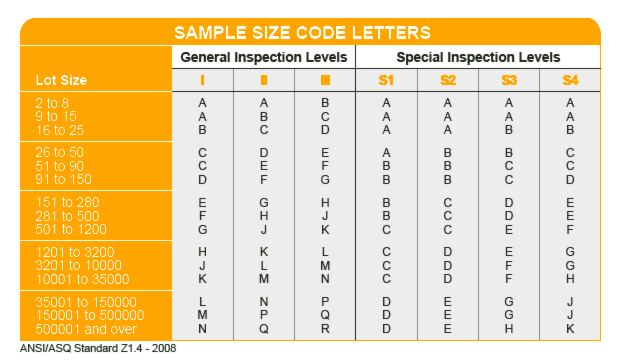

There are basically two tables. The first one tells you which ‘code letter’ to use. Then, the code letter will give you the sample size and the maximum number of defects that can be accepted.

First table: sample size code letters

How to read this table?

If you follow my example, I assume your ‘lot size’ is comprised between 3,201 pcs and 10,000 pcs, and that your inspection level is ‘II’. Consequently, the code letter is “L”.

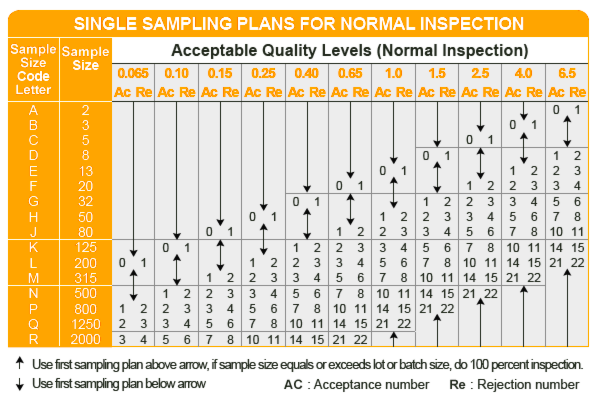

Second table: single sampling plans for level II inspection (normal severity)

How to read this table?

Our code letter is “L”, so you will have to draw 200 pcs randomly from the total lot size. Besides, I assume you have set your AQL at 2.5% for major defects and 4.0% for minor defects. Therefore, here are the limits: the products are accepted if NO MORE than 10 products with major defects AND NO MORE than 14 products with minor defects are found. For example, if you find 15 products with major defects and 12 products with minor defects, the products are refused. If you find 3 with major defects and 7 with minor defects, they are accepted.

Are you performing random quality inspections? Use the free AQL calculator from Testcoo to quickly find your sample size:

Note:

In quality inspections, the number of defective products is only one of the criteria. It is sometimes called “quality”, or “quality findings”. The other criteria are usually on the inspector’s checklist, which typically includes:

- -Packaging conformity (barcodes, inner packing, cartons, shipping marks…).

- -Product conformity (aspect, workmanship…). If all the products are in red color instead of orange, there is no need to count each sample as a defect. It makes more sense to refuse for product conformity.

- -Specific tests defined in the inspection checklist (they might not be performed on all inspected samples if they are time-consuming or destructive).

Need help with inspecting your production?

Get in touch with me and I will give you a tailored recommendation or quotation. TESTCOO can probably help you.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index