Sustainable Footwear Manufacturing: How Third-Party Inspections Ensure Green Claims Are Real

In today’s global market, sustainability is no longer a buzzword, it’s a demand. Consumers want footwear that doesn’t just look good and feel good, but is also good for the planet. From recycled rubber soles to vegan leather uppers, brands are racing to advertise eco-friendly materials and processes. But with this green revolution comes a challenge: How do buyers and consumers know these sustainability claims are real?

This is where third-party inspections play a crucial role. Independent inspections help verify whether factories actually follow sustainable practices, use genuine eco-friendly materials and maintain ethical working conditions. For global footwear buyers, investing in third-party inspections is no longer optional, it’s a vital step to protect their brand’s reputation and build consumer trust.

In this blog, we’ll explore why sustainability is trending in footwear manufacturing, what risks buyers face and how third-party inspections ensure that green claims hold up under scrutiny.

Why Sustainability Matters in Footwear

The footwear industry has a significant environmental footprint. According to a report by Quantis, shoes account for 1.4% of global greenhouse gas emissions equivalent to the entire emissions of a country like Italy.

From energy-intensive leather tanning to synthetic materials made from petroleum, traditional footwear manufacturing can harm the planet in multiple ways:

- High water consumption and pollution

- Chemical use in tanning and dyeing

- Waste from off-cuts and defective products

- Non-biodegradable components that end up in landfills

To counter this, leading brands are investing in:

- Recycled and upcycled materials (e.g., ocean plastics, recycled rubber)

- Bio-based alternatives (e.g., mushroom leather, pineapple fibers)

- Closed-loop production (take-back programs, recyclability)

- Cleaner energy and reduced carbon emissions

- Fair labor practices

However, sustainability is complex. It’s not enough for a factory to claim they use “eco leather” or “recycled rubber”, buyers must ensure these claims are backed by evidence.

Read: Decoding 2025's Sustainability Audits: A Brand's Survival Guide

The Risk of Greenwashing in Footwear

Greenwashing making misleading claims about a product’s environmental benefits is a growing concern. Some factories might:

- Substitute certified recycled materials with cheaper, non-certified alternatives.

- Mislabel synthetic leather as “vegan” without disclosing it’s still plastic-based.

- Ignore pollution controls during production while promoting “eco-friendly” branding.

- Fail to provide credible documentation for sustainable practices.

For brands, being exposed for greenwashing can lead to:

- Loss of consumer trust

- Legal challenges or fines in markets with stricter sustainability laws

- Social media backlash that damages reputation

To safeguard their supply chain and reputation, brands need independent verification. This is where third-party inspections come in.

What is a Third-Party Inspection in Footwear?

A third-party inspection is an independent assessment conducted by an unbiased company. Unlike an in-house QC team or the supplier’s self-declaration, a third-party inspector has no stake in the factory’s operations. This makes their reports credible and trustworthy.

In footwear, inspections typically include:

- Material Verification - Are the materials really what they claim to be?

- Process Checks - Are sustainable processes actually followed?

- Chemical Testing - Are banned or harmful substances present?

- Product Quality - Does the final product meet buyer standards?

- Packaging and Labeling - Are sustainability claims accurate on labels and tags?

Read more: Key Quality Checks in Footwear Inspection

How Third-Party Inspections Support Sustainable Claims

Let’s break down how third-party inspections strengthen sustainability in footwear manufacturing.

1. Verifying Sustainable Materials

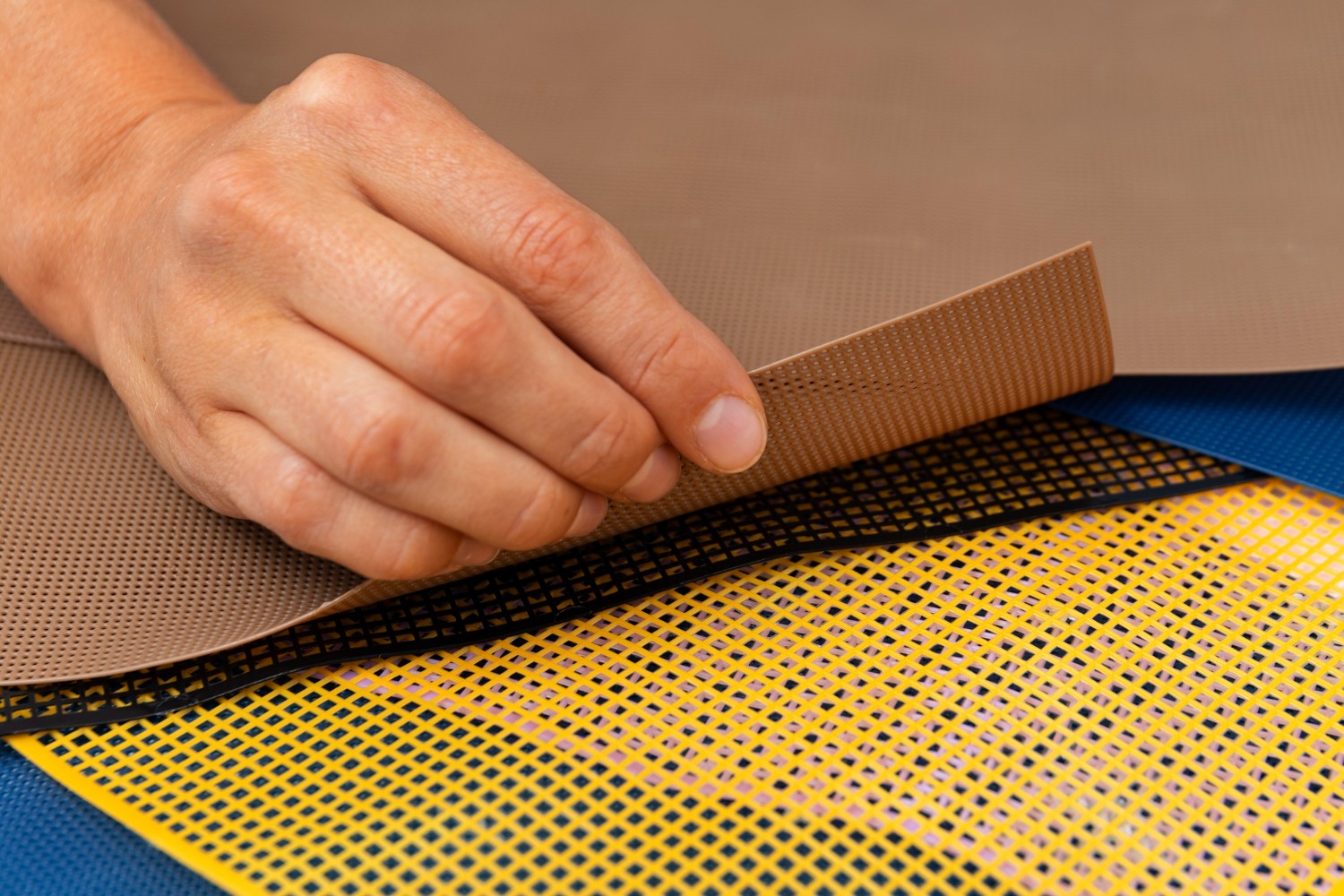

One of the most common green claims is about materials - recycled polyester, organic cotton laces, natural rubber soles or vegan leather. But how do buyers know if these materials are authentic?

An inspector checks:

- Certificates of origin - Are the recycled or organic materials certified by credible bodies like GRS (Global Recycled Standard) or GOTS (Global Organic Textile Standard)?

- Supplier chain traceability - Does the factory have documented proof of sourcing?

- Physical checks - Inspectors may conduct on-site spot checks to ensure the materials match documentation.

- Sample testing - Random lab tests can detect material composition, ensuring no harmful blends are used.

2. Monitoring Chemical Compliance

Sustainability also means avoiding harmful chemicals. Many countries have strict limits on substances like azo dyes, formaldehyde, lead or phthalates.

Third-party inspections include chemical lab testing to check:

- Leather tanning chemicals

- Adhesives and glues

- Dye residues

- Surface treatments

This ensures that the final shoe is safe for consumers and the environment.

3. Checking Waste and Emissions Management

A factory’s sustainability commitment isn’t just about the shoe, it’s about how the shoe is made.

Inspectors can assess:

- Waste disposal methods: Are leather scraps and rubber off-cuts properly recycled or disposed of?

- Emissions: Does the factory control air pollutants from production?

- Water treatment: Is wastewater from dyeing or tanning treated before discharge?

Read more about Environmental Management Audit

4. Validating Social Responsibility

Sustainable footwear includes fair working conditions - no forced labor, fair wages and safe work environments. Many brands combine sustainability checks with social audits such as SMETA or SA8000.

A third-party audit checks:

- Compliance with local labor laws

- Worker health and safety

- No child labor or forced labor

- Fair wages and working hours

Combining sustainability inspections with social audits gives buyers a full view of a factory’s ethics.

5. Inspecting Packaging and Labeling

Many sustainable brands promote minimal, recyclable packaging. Inspectors can check whether:

- Packaging uses recycled or biodegradable materials

- Labels accurately reflect material content and certifications

- No misleading green claims appear on swing tags or boxes

Read more: Inside a Product Inspection Checklist: Your Guide to Quality Control

When Should Footwear Buyers Arrange Third-Party Inspections?

Inspections can happen at various stages:

- Initial Production Check (IPC): Verify materials and supplier certifications before mass production.

- During Production (DUPRO): Monitor processes, waste management and chemical handling.

- Final Random Inspection (FRI): Inspect finished goods for quality, material compliance, packaging and labeling.

- Lab Testing: Send random samples for chemical and material analysis.

A combination of inspections gives buyers the strongest assurance.

↵ ↵

Key Standards and Certifications to Look For

To strengthen sustainability claims, buyers should look for recognized standards such as:

- GRS (Global Recycled Standard) - Confirms recycled material content.

- GOTS (Global Organic Textile Standard) - For organic cotton components.

- OEKO-TEX® Standard 100 - Tests for harmful substances.

- LWG (Leather Working Group) - For environmentally responsible leather production.

- ISO 14001 - For environmental management systems.

- SA8000 / SMETA - For social accountability.

A reputable third-party inspection company can help verify these certifications and integrate them into inspection checklists.

Read more about the Testcoo’s Supplier Verification and Certification services

Benefits for Footwear Brands

- Credibility: Independent reports build trust with eco-conscious consumers.

- Risk Reduction: Avoid legal penalties and PR disasters related to false green claims.

- Supplier Improvement: Factories improve processes to meet buyer standards.

- Competitive Advantage: Brands with verified sustainability credentials stand out.

- Traceability: Transparent supply chains are increasingly required by regulators.

How to Choose a Reliable Third-Party Inspection Partner

If you’re a buyer or sourcing manager, here’s what to look for:

- Experience in footwear and sustainability inspections.

- Accredited labs for chemical testing.

- Knowledge of local regulations and international standards.

- Unbiased, transparent reporting.

- Ability to provide combined audits (product, process and social).

- Good reputation with references from global brands.

The future of footwear is green but true sustainability requires action, not just marketing slogans. For brands and buyers, verifying claims through independent third-party inspections is the surest way to protect consumers, the planet and your reputation.

By partnering with trusted inspection providers, you can confidently tell your customers: “These shoes really are as green as we say.”

Testcoo is a trusted third-party inspection partner for global footwear brands. From verifying recycled materials to chemical testing and social audits, we help you ensure your sustainability claims are authentic.

Contact us today to discuss how we can support your sustainability goals in footwear manufacturing.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index