Garment Sampling Process: A Critical Step in Quality Assurance

The garment industry thrives on quality, precision and efficiency. Before bulk production begins, brands and manufacturers rely on the garment sampling process to ensure that the final product meets quality standards, design expectations and buyer requirements. Sampling is a critical step in quality assurance, helping to minimize defects, streamline production and improve customer satisfaction.

This blog explores the importance of garment sampling, its different types, the step-by-step process and how third-party inspections like Testcoo ensure quality compliance.

What is Garment Sampling?

Garment sampling is a crucial quality control step in apparel manufacturing, ensuring that the final product meets design specifications, fabric standards and buyer expectations before bulk production begins. This process helps brands and manufacturers detect and rectify potential defects, avoiding costly errors and production delays. It plays a vital role in quality assurance, customer satisfaction and brand reputation. By following industry standards and conducting rigorous inspections - often with third-party inspection companies like Testcoo - brands can ensure that every garment meets required specifications. A well-structured sampling process minimizes defects, streamlines production and enhances efficiency, making it an essential practice in the fashion and textile industry.

Read more: Understanding ISO 2859: A Comprehensive Guide to Sampling for Quality Inspection

Why is the Garment Sampling Process Important?

Before mass production begins, manufacturers create samples to verify design accuracy, fabric selection, fit and overall workmanship. This process helps identify potential defects and allows necessary modifications to be made early, preventing costly errors in bulk production. A well-structured sampling process not only improves efficiency but also enhances a brand’s reputation by delivering high-quality, defect-free garments to the market. The garment sampling process plays a pivotal role in quality assurance for several reasons:

- Prevents Costly Mistakes – Identifying design flaws, fabric issues, or production errors before bulk manufacturing.

- Ensures Compliance with Buyer Specifications – Matching approved designs, fabric choices, colors and sizing.

- Facilitates Smooth Production – Allowing manufacturers to refine production techniques and avoid disruptions.

- Enhances Brand Reputation – Delivering high-quality, defect-free garments increases customer trust.

- Speeds Up Approvals – Buyers and brands can quickly approve production once they verify a sample.

Types of Garment Samples

Garment sampling involves different types of samples at various production stages. Here are the most common ones:

1. Proto Sample (Prototype Sample)

- The first sample created based on the initial design and fabric selection.

- Helps in understanding the garment’s feasibility and identifying design changes.

2. Fit Sample

- Focuses on the fit, size and overall comfort of the garment.

- Often sent to fit models to assess drape and mobility.

3. Salesman Sample (SMS)

- Created for marketing and sales presentations.

- Used to showcase the final product to buyers, retailers and distributors.

4. Pre-Production Sample (PPS)

- The most critical sample that determines production readiness.

- Must be approved by the buyer before mass production starts.

5. Size Set Sample

- A set of samples created in all sizes for fit verification.

- Ensures consistency in measurements across various sizes.

6. Production Sample (Top of Production - TOP Sample)

- Taken from the first bulk production batch.

- Confirms that mass production maintains the quality and specifications of approved samples.

7. Shipment Sample

- A final sample taken from the completed production before shipment.

- Used for last-minute checks and approvals.

Step-by-Step Garment Sampling Process

A well-structured sampling process ensures that the final product meets buyer expectations. Here’s a detailed breakdown of the garment sampling process:

Step 1: Design and Tech Pack Creation

- The buyer provides a tech pack, including sketches, fabric details, measurements and finishing requirements.

- Manufacturers use this guide to create the first proto sample.

Step 2: Prototype Sample Development

- The proto sample is developed based on the tech pack and sent for buyer feedback.

- Adjustments are made based on comments regarding fabric, fit and design.

Step 3: Fit and Size Sample Creation

- A fit sample is created to check garment fitting and ease of movement.

- Manufacturers may send size set samples to ensure uniformity across different sizes.

Step 4: Salesman Sample Production

- Once the fit sample is approved, salesman samples are produced for marketing and client approvals.

- Brands use these samples for photoshoots, advertisements and presentations.

Step 5: Pre-Production Sample (PPS) Approval

- Before bulk production starts, a pre-production sample (PPS) is developed.

- This sample undergoes rigorous checking by buyers, ensuring fabric, color and trims are correct.

- Third-party quality inspection services, like Testcoo, play a key role in verifying PPS.

Step 6: Bulk Production and Quality Control

- Once the PPS is approved, mass production begins.

- A TOP (Top of Production) Sample is collected from the first batch to ensure consistency.

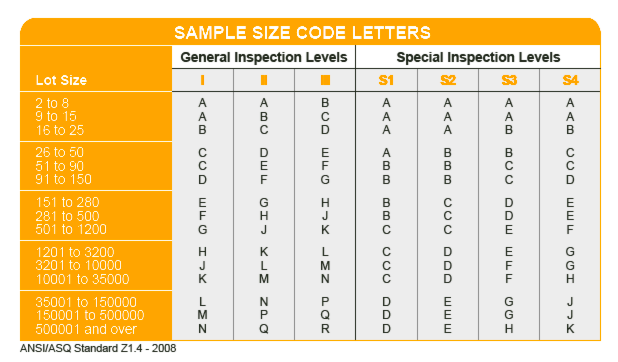

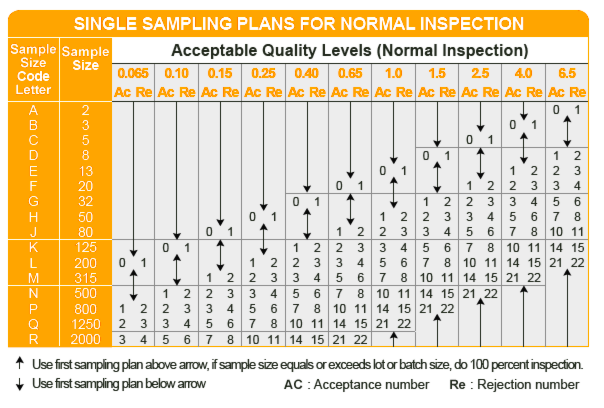

- Random sampling is conducted following the AQL (Acceptable Quality Limit) method to check for defects.

Read more: Understanding AQL in Product Inspections: A Complete Guide to Quality Control

Step 7: Final Inspection and Shipment Approval

- A shipment sample is taken for the final quality check before dispatch.

- Third-party inspection companies perform pre-shipment inspections to verify that all bulk production aligns with approved samples.

- Once approved, the garments are packed and shipped to retailers or buyers.

Challenges in the Garment Sampling Process

While garment sampling is a crucial step in ensuring quality, it comes with its own set of challenges that manufacturers, buyers and quality inspectors must navigate. From delays in approvals to inconsistencies in production, various factors can affect the efficiency and accuracy of the sampling process. Understanding these challenges is essential for brands to streamline their quality control measures and avoid costly errors in bulk production. Despite its importance, the garment sampling process faces several challenges:

- Fabric and Trim Variations – Differences between sample and bulk production materials.

- Inconsistencies in Fit and Sizing – Minor size deviations can impact customer satisfaction.

- Production Delays – Late sample approvals can slow down the entire manufacturing cycle.

- Lack of Proper Communication – Misinterpretations of buyer requirements can lead to rejections.

- Variation in inspection standards across manufacturing countries - Understanding regional differences help brands streamline their quality assurance process.

Read more: Why Apparel Inspections Differ in China, India and Bangladesh

To overcome these challenges, early sampling approvals, clear documentation and third-party quality control inspections are essential.

How Testcoo Ensures Quality in Garment Sampling

The garment sampling process is a crucial quality assurance step that ensures consistency, compliance and customer satisfaction. From the first proto sample to the final shipment sample, each stage plays a vital role in delivering high-quality apparel.

Testcoo, a leading third-party inspection and quality control company, helps brands and manufacturers in multiple ways:

Pre-Production Inspections – Also known as Initial production Check (IPC) is used to identify defects, color accuracy, stitching and fabric quality.

During Production Inspections (DUPRO) – Conducting quality checks during mass production to catch defects early.

Final Random Inspections (FRI) – Using AQL-based sampling methods to evaluate bulk production before shipment.

Compliance Audits – Ensuring factories follow ethical, social and environmental compliance norms.

Read more: The Ultimate Guide to Garment and Apparel Inspection: Ensuring Quality and Perfection

By working with a third-party inspection partner like Testcoo, brands can reduce risks, avoid costly rejections and ensure that every garment meets quality expectations.

Partnering with Testcoo for independent sampling inspections and quality control guarantees that garments meet buyer expectations, reduce defects and streamline production.

Are you looking for reliable third-party garment inspection services? Contact Testcoo today to ensure flawless quality in every step of your apparel production.

Related Articles

Read MoreFree Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index