ASTM vs. ISO: Key Differences in Global Standards for Quality & Compliance

In today’s interconnected global economy, standards play a crucial role in ensuring quality, safety and consistency across industries. Among the most recognized and widely adopted standard-setting organizations are the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Both have shaped how products are designed, manufactured, tested and distributed worldwide.

Although ASTM and ISO share the same goal, developing standards that protect consumers and promote trade, they differ in their origins, structure, scope and application. For businesses that operate internationally, understanding these differences is essential for compliance, smooth trade operations and maintaining product credibility.

This blog explores ASTM vs. ISO, breaking down their history, purpose, similarities, key differences and implications for industries worldwide.

What Are ASTM Standards?

The American Society for Testing and Materials (ASTM), now officially known as ASTM International, was founded in 1898 in the United States. Originally created to address disputes in the steel industry, ASTM has grown into one of the world’s largest standard development organizations.

ASTM develops consensus-based, voluntary standards that cover a wide range of materials, products, systems and services. With over 12,000 ASTM standards published, they are widely used in industries such as:

- Construction (cement, steel, concrete)

- Consumer goods (toys, textiles, packaging)

- Petroleum and energy

- Medical devices and pharmaceuticals

- Environmental testing

One of the strengths of ASTM standards is their technical depth. They often define detailed test methods, material specifications and procedures that ensure product consistency.

Example:

- ASTM D123: A standard terminology for textiles.

- ASTM F963: Standard consumer safety specification for toy safety.

What Are ISO Standards?

The International Organization for Standardization (ISO) was established in 1947 in Geneva, Switzerland. Unlike ASTM, ISO is a global, non-governmental federation of national standards bodies from 168 member countries. Its mission is to create international standards that support global trade, innovation and sustainability.

ISO standards focus on management systems, process efficiency and product quality. They are broader in scope than ASTM and are widely adopted across industries for global compliance.

ISO has published more than 25,000 standards, covering areas such as:

- Quality management (ISO 9001)

- Environmental management (ISO 14001)

- Occupational health and safety (ISO 45001)

- Food safety (ISO 22000)

- Information security (ISO/IEC 27001)

Example:

- ISO 9001: Sets requirements for a quality management system.

- ISO 14001: Establishes standards for environmental management systems.

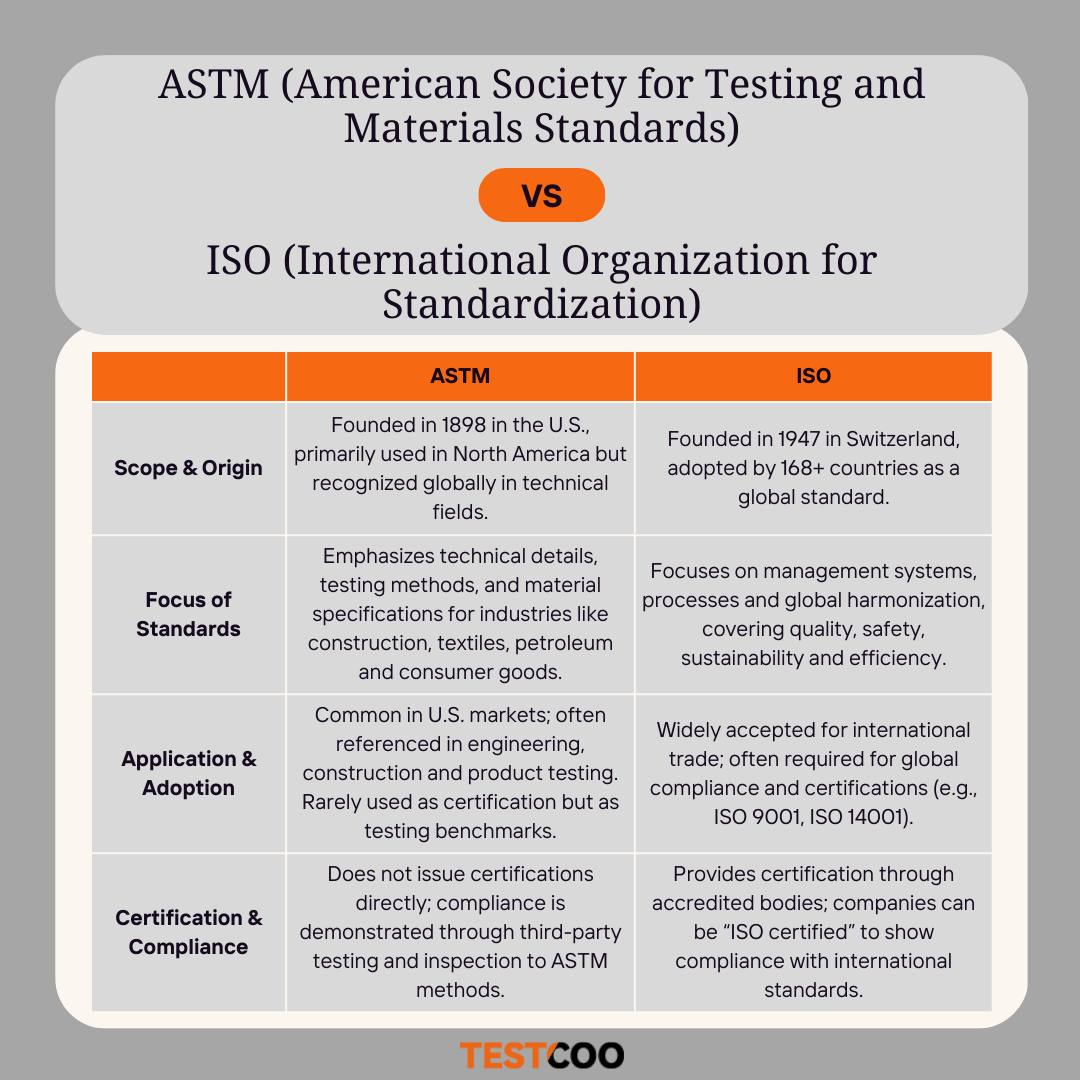

ASTM vs. ISO: Key Differences

Although both organizations contribute significantly to global standardization, they differ in approach, structure and application.

1. Geographic Scope

- ASTM: Originated in the U.S. and is most widely used in North America. However, ASTM standards are also recognized internationally, especially in industries like construction and textiles.

- ISO: Global in nature, with participation from 168 member countries. Its standards are universally recognized and often serve as a benchmark for international trade.

2. Focus of Standards

- ASTM: Technical and material-focused. Standards often specify testing methods, product requirements and material properties.

- ISO: Process and management-focused. Standards often emphasize system efficiency, safety and sustainability.

3. Development Process

- ASTM: Uses a consensus-driven process with committees made up of experts, manufacturers, consumers and academics. The emphasis is on technical details and test methods.

- ISO: Standards are developed by national representatives from member countries. The process is consensus-based but focuses on global applicability and harmonization.

4. Industry Adoption

- ASTM: Commonly used in the U.S. and North America, particularly in engineering, construction and manufacturing.

- ISO: Adopted globally across industries and often required for international certification and trade.

5. Certification

- ASTM: Generally does not provide certification. Instead, companies use ASTM standards to prove compliance through testing and inspection.

- ISO: Provides certification through accredited bodies. For example, a company can be ISO 9001 certified to show it meets quality management requirements.

6. Example Comparison

- ASTM F963 (Toy Safety) vs. ISO 8124 (Safety of Toys): Both cover toy safety but may differ in test methods and regional requirements. Companies exporting toys globally often need to comply with both standards.

ASTM and ISO: Where They Overlap

While ASTM and ISO differ, they also collaborate in certain areas. Some ASTM standards have been adopted by ISO and vice versa, under the “dual logo” agreement.

For example:

- ASTM E29 (significant figures in test data) was also adopted as ISO 80000.

- ISO/ASTM 52900 defines standard terminology for additive manufacturing (3D printing).

This collaboration reduces duplication and ensures greater harmonization across industries.

Read more: Decoding EN, IEC, ISO and ITU Standards: Your Key to Global Market Success

Why Do These Differences Matter?

For businesses, understanding ASTM vs. ISO is not just about technical details, it’s about market access, compliance and reputation.

- Global Trade

- U.S.-based companies may rely on ASTM for domestic operations but must comply with ISO standards to export to Europe, Asia or other regions.

- Quality and Safety Assurance

- ASTM ensures product-specific safety (e.g., a toy, textile or steel product passes safety tests).

- ISO ensures that the system behind production (e.g., quality management or environmental management) is reliable.

- Cost and Efficiency

- Compliance with both ASTM and ISO may increase testing and certification costs, but it enhances market credibility.

- Consumer Trust

- Products compliant with ISO or ASTM standards signal reliability and safety, which improves consumer confidence.

ASTM vs. ISO: Industry Applications

1. Construction and Engineering

- ASTM: Standards for concrete strength, steel quality and building materials.

- ISO: Standards for environmental management (ISO 14001) and occupational safety (ISO 45001).

2. Textiles and Apparel

- ASTM: Fabric testing, colorfastness, shrinkage, flammability (ASTM D123, ASTM D4151).

- ISO: Broader textile testing under ISO 105 (colorfastness) and ISO 3758 (care labeling).

3. Consumer Goods

- ASTM F963: Toy safety widely recognized in the U.S.

- ISO 8124: Equivalent toy safety standard for global markets.

4. Food and Agriculture

- ASTM: Packaging material standards, contamination testing.

- ISO 22000: Comprehensive food safety management system standard.

Choosing Between ASTM and ISO

When deciding between ASTM and ISO standards, the right choice often depends on your target market, industry requirements and customer expectations. ASTM, rooted in the U.S., provides detailed technical standards and testing methods that are widely used in North America and in industries requiring material or product-specific testing. ISO, on the other hand, offers globally recognized management and process standards that facilitate international trade and certification. Many companies choose both ASTM for technical product compliance and ISO for broader global recognition ensuring quality, safety and competitiveness in both domestic and international markets. The choice depends on:

- Target Market: For U.S. markets, ASTM is often sufficient. For global exports, ISO compliance is critical.

- Industry Requirements: Some industries mandate ASTM test methods, while others require ISO certification.

- Customer Expectations: Global buyers increasingly demand ISO-certified suppliers.

In many cases, businesses pursue both ASTM and ISO compliance to stay competitive.

Future of ASTM and ISO Standards

As industries evolve with digitalization, sustainability and new technologies, both ASTM and ISO are updating their standards to remain relevant.

- Sustainability focus: ISO has expanded environmental and energy management standards, while ASTM develops eco-friendly material standards.

- Technology shift: Joint standards in additive manufacturing, AI and digital supply chains are emerging.

- Global harmonization: Expect more collaboration between ASTM and ISO to simplify compliance for multinational companies.

Partner with Testcoo for your ASTM & ISO Compliance needs

When it comes to global standards, ASTM and ISO serve as two pillars of quality, safety and reliability. While ASTM focuses on technical test methods and material properties, ISO emphasizes management systems and international harmonization. For companies operating in both domestic and international markets, understanding and applying both ASTM and ISO standards is not optional, it’s a competitive necessity. Aligning with these standards not only ensures compliance but also builds consumer trust, brand reputation and global market access. By strategically leveraging ASTM’s technical depth and ISO’s global reach, businesses can achieve excellence in both product quality and international trade.

At Testcoo, we understand that compliance with both ASTM and ISO standards is critical to building trust, ensuring safety and gaining access to global markets. Our expert auditors and inspectors provide reliable, independent assessments tailored to your industry, whether it’s consumer goods, textiles, construction or electronics. By partnering with us, you gain a proactive quality partner who helps you navigate complex requirements, minimize risks and maintain a competitive edge. With Testcoo’s experience and global reach, you can be confident that your products and processes consistently meet international benchmarks for quality and compliance.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index