10 Major Inspection Criteria For Softgoods

What are the key inspection criteria for soft goods? What can you do to maintain top-class standards and quality levels for the soft line products in your supply chain as a purchaser or a trader?

- Materials

- Colors

- Style

- Accessories

- Weight

- Workmanship

- Measurements

- Labeling and Hangtags

- Assortment

- Markings

What are Soft Goods

Soft goods are products that are literally soft and less durable. Here are some examples of soft goods:

- -Apparel

- -Backpacks

- -Bags

- -Bedding

- -Carpets

- -Costumes

- -Curtains

- -Mats

- -Paper products

- -Pillows

- -Textiles

- -Towels

Soft goods are mostly consumer goods. Read on for a guide of major inspection standards for soft line products.

What are the Key Inspection Criteria for Soft Goods

1 Materials

A lot goes into inspecting materials for your soft goods like garment. While some may tend to purchase things at a lower price, this will ultimately cost more in the long term if the materials are of poor quality. It’s well worth spending extra money on material inspection. Here you can check: from visual aspect, is it clean and neat, or damp with mildew? What about the hand touch compared with the reference sample? Is it hard, soft, smooth or spongy even without a reference sample?

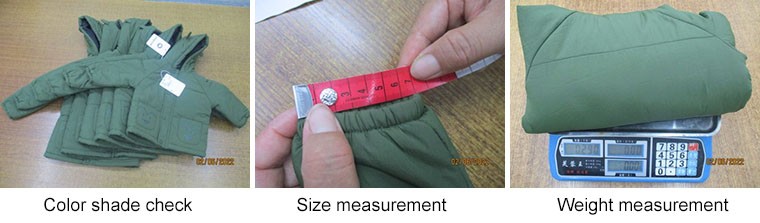

2 Colors

The color inspection is intended to determine whether the color match the sample swatches, reference sample or color chart. The various components (e.g. of a shirt, blouse, pants etc.) must be of the same shade. For piece-goods, is the shading of the dye of the printing uniform throughout? What is the ratio of different shade lots?

3 Style

This part is to test whether the style in conformity with the description or the reference sample, including methods of sewing, style of printing, etc.

4 Accessories

For accessories, like buckles, belts, ornamentation, must match the sample and description. For example, buckles should be smooth, well plated without burrs and well positioned at the correct place.

5 Weight

Weight inspection can ensure each unit is with correct accessories and not jerry-built. For fabrics, the mtr/yd weight corresponds to the weight of the bulk production.

6 Workmanship

In this part, it introduces much room for error as soft goods are made by people and machines working on raw materials. For garments, is the sewing straight without puckering or skipped and broken stitches? Are the accessories such as zippers, pockets and ornaments, positioned and attached correctly? Are pockets aligned with each other? For fabrics, weaving faults in excess of tolerance must be checked and recorded on the special inspection and report forms provided.

7 Measurements

For garments, as a guideline, 10-20% of the sample size must be measured (at least 3 per size) in accordance with the measurement specifications and tolerances provided by the client. If the client has not specified any particular tolerances for the measurements, tolerances indicated on the Measurement Tolerance Sheet will be applied.

For fabrics, the measuring can be done over a mechanical inspection table equipped with a yard/meter counter. Considering that the accuracy of such counters is sometimes doubtful, it may be prudent to check and measure a few pieces in the traditional manner. For fabric (mostly in grey state) which comes in yard/meter lapped folding, the measurement determination is quick and accurate.

8 Labeling and Hangtags

Most articles are provided with a label or a hangtag. Some countries have stringent laws regarding the compulsory labeling of articles. The USA have the “Labeling Act” which includes details such as composition, size, care symbols, and garments must bear an “RN” (recall number/ a registered identification #) allowing to be recalled in case of need.

The European Economic Community (EEC) compulsorily stipulates that all imported articles show the fiber composition of fabrics and garments.

During inspection for quality, the checking of the labels must not be neglected. For example, the indication on the hangtag must be identical with the sewn-in label in the garment and the size must be consistent.

9 Assortment

The assortment check is also important. Large retail chain stores distribute standard packed items to their numerous sales outlets, e.g. a master carton will contain 50 red, 50 black, 30 green and 20 blue ones. Some unscrupulous manufacturers, for lack of a specified color or size, may be tempted to make up the shortage by some other colors or sizes.

10 Markings

External markings on cases/cartons/boxes/bales should comply with client’s particular requirements. In certain case the buyer insists on neutral packing which means that manufacturer’s/supplier’s name and country are not shown.

How to Start Inspection for Soft Goods with TESTCOO

There are a range of different inspections and tests for general merchandise products and it’s totally important to spend more on inspection for long term running for a company. Today, using a third-party inspection company is convenient with an excellent price, who can help to ensure your products meet your customers’ expectations including materials, style, color, etc. As a third-party inspection company with intelligent management for quality assurance, TESTCOO aims to build the world’s most influential third-party inspection service center. In TESTCOO, you can make an inspection order in 5 minutes and get your detailed report in 48 hours. Try TESTCOO today to find out how we can help to improve your products quality.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index