【测库课堂】空调验货及测试

炎炎夏日,怎么能少的了空调,那么空调是怎么验货的呢?测库专业技术主管讲解空调验货方法及标准。

一、电器分类

电热器具:装有电热元件而不带有电动机的器具。

电动器具:装有电动机而不带有电热元件的器具。

联合型器具:装有电动机和电热元件的器具

二、电热器具

电热类有电热水壶/电热咖啡壶/电熨斗/三明治炉/多士炉/取暖器/烤箱等

电动类有吸尘器/打蛋器/搅拌器/电风扇/榨汁机等

联合型器具有电吹风/加湿器等

大型家电有空调/冰箱/洗衣机/抽油烟机等.

三、空调大体有下面几种:

1.分体式空调

2.立柜式空调

3. 窗式空调

4. 吊顶式空调

四、外观注意事项:

1. 如果是塑料件, 那需要注意壶身和底座的颜色是否一致. 有可能材料不一致而导致有色差, 那需要查看客人订单, 参考样品, 彩盒产品照片.

2. 塑料件注意飞边, 缩水, 气纹, 划痕等外观不良. 各个装配部位缝隙应该均匀, 间隙不要大于0.8mm. 不要有松动/变形等不良现象.

3. 金属件, 表面应该注意划痕, 锈斑, 电镀不良及指纹印等不良情况, 外观应该符合客人订单及样品. (例如不锈钢镜面及哑光效果)

4. 最好大货和彩盒照片放一起拍张照片.

五、空调验货基本测试:

1.Transportation drop test

No critical & Major issue found on package & product after (10 times) drop test according to the standard of ISTA 1A.

2.Product Size /power cord length / WeightMeasurement (量尺寸的时候尺子拉直, 如果卷尺头子有松动, 可以从10cm位置开始测量)

3.Bar code scan check

二维码(app下载个二维码扫描软件, 可以扫描出链接, 如果不能连上, 拍链接照片备注即可)

4.Assembly/installation check

5.Full function check (including the function which only can be checked after fully assembling/installation.)

6.Coating adhesive Tape Test

7.High voltage test

8.Power on the check (The good condition samples should be operating at full load (preferable) at least 4 hours at rated voltage or time reference the user instruction if less than 4 hours.

after testing the samples should pass the hi-voltage check, function check, earth continuity check, etc., and no defect found.)

9.Earth continually test if applicable

10.Power consumption check

11.Power cord strain relief test

(如果没有拉力器, 可以吊相应的重量, 这个测试最好不要备注没有仪器)

12.Internal workmanship and critical component check.

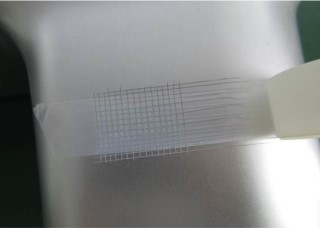

13.Rubbing test for rating label and adhesive Test for printing, marking, and logo

14.Stability test (Appliances(other than fixed appliances and hand-held appliances)is placed in any normal position of use on a plane inclined at an angle of 10°to the horizontal, the supply cord resting on the inclined plane in the most unfavorable position.The appliance shall not overturn.)

15.Timer accuracy check (timer should be set as per instruction manual and the actual time should be measured, the timer is set for 2 hours.if no client requirement, the tolerance requirement is: electronics type +/-1minutes, mechanical type +/-10%)then power off, and then power the unit on again with 10 seconds.)

16. Drop test for remote controller (Freelydrop the unit through a height of 1000mm onto a smooth concrete floor with 3mmTvinyle tile 3 times by different position, check the product unit after each drop. Any malfunction /construction broken or other major defect be found.)

17. Gas leakage check (use the gas detector to check the connection point between tube and compressor etc. gasline. no gas leakage found.)

18. Noise check (apply rated voltage to the unit and operating at the highest setting, then measure the noise with the tester 1m away from the unit. the noise level should be within the requirement.)

六、基本结构及注意事项:

-产品基本都有logo-都需要做丝印粘贴测试

-内部检查-核对CDF

-外箱/说明书/产品序列号要一致

-出风口温度测试一下, 是否和设定温度基本一致.