Guidelines for Product Inspection in India

TESTCOO is your third-party inspection company in India for all your quality control needs. With our QC team in India’s key markets, TESTCOO product inspection services allow the buyers to check that their product specifications and quality, functionality and performance requirements have been met.

TESTCOO offers different types of product inspection and quality control services in India which can be conducted from the initial production setup stage, right through to the pre-shipment and container loading stages.

Learn more about our product inspection services in India: Quality Control Inspection and Audit in India

Product Inspection in India

India's manufacturing sector encompasses a wide range of industries, including textiles, consumer goods, electronics, machinery, automotive, pharmaceuticals and chemicals. The country's diverse industrial landscape caters to both domestic consumption and export markets, offering opportunities for various businesses across different sectors.

While there are many benefits making India a sought-after sourcing destination worldwide, navigating the complex supplier landscape, manufacturing processes, and regulatory environments can take time and money. In India, the failure rate for exported products is relatively higher than in other countries, quality control remains a significant challenge for exporters and the need for more rigorous quality control processes among many manufacturers. Product inspections are essential quality control measures to ensure that goods meet specified standards and requirements before reaching the hands of consumers. There are various types of product inspections tailored to different stages of production, industry-specific needs, and quality assurance objectives. Here are some common types of product inspections:

- Initial Production Check (IPC):

- Conducted at the early stages of production, typically after the initial production samples are ready.

- Aimed at verifying that raw materials, components, and production processes meet specified requirements and standards.

- Helps identify potential issues and deviations from quality standards before mass production begins, allowing for timely corrective actions.

- During Production Inspection (DUPRO) or Inline Inspection:

- Carried out during the manufacturing process when a certain proportion of the production is completed.

- Focuses on monitoring product quality, detecting defects, and ensuring compliance with production standards and specifications.

- Enables proactive intervention to address quality issues and maintain consistency in product quality throughout the production process.

- Pre-shipment Inspection (PSI) or Final Random Inspection (FRI):

- Conducted once the entire production is completed and goods are ready for shipment.

- Involves a comprehensive assessment of finished products to verify conformity with pre-established quality criteria, specifications, and regulatory requirements.

- Helps identify any remaining defects, deviations, or non-compliance issues before goods are shipped to customers, minimizing the risk of costly returns or rejections.

- Loading Supervision:

- Carried out at the factory or warehouse during the loading of goods into shipping containers or vehicles.

- Ensures proper handling, packaging, and loading procedures are followed to prevent product damage, contamination, or loss during transit.

- Verifies the accuracy of the quantity, assortment, and condition of goods loaded for shipment, reducing the risk of discrepancies or disputes upon delivery.

- Supplier Evaluation and Audit:

- Assessments conducted to evaluate the capabilities, performance, and compliance of suppliers or manufacturing partners.

- Involves on-site inspections, audits, and assessments of facilities, processes, quality management systems, and adherence to regulatory requirements.

- Aims to ensure supplier reliability, product consistency, and adherence to ethical, social, and environmental standards.

Each type of product inspection serves a specific purpose and contributes to overall quality assurance efforts in the manufacturing process. By implementing a combination of these inspections, companies can minimize quality risks, maintain product integrity, and enhance customer satisfaction. Contact us to get a quote.

Learn more about the types of inspections in India: What is Quality Control – A complete guide

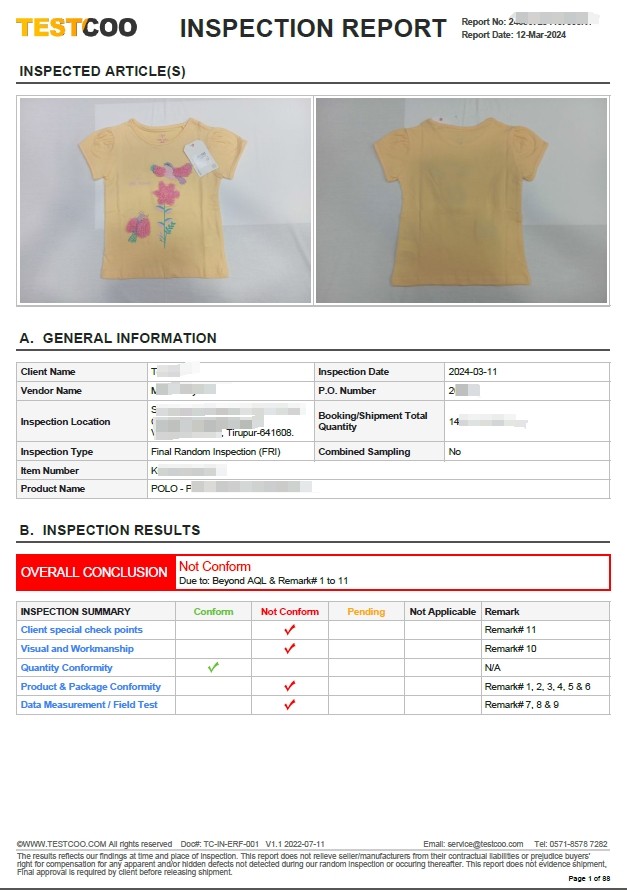

DOWNLOAD A PRODUCT INSPECTION SAMPLE REPORT IN INDIA

TESTCOO provides the final inspection reports detailing any defects found so that you can take immediate corrective action on time.

Guidelines for booking a Product Inspection in India

The main objective of a production inspection is to assure all products manufactured by the suppliers in India meet specifications and quality standards, approved samples and procedures.

While inspections are challenging, having the process run smoothly is achievable with proper preparation. Here is what buyers need to know to take full advantage of product inspections and booking it when you set up the importing and booking a quality inspection service.

AQL TABLE

Audits will be conducted using AQL (Acceptance Quality Level ) ISO 2859-1 Table.

Among the quality control methods, inspection is the most-frequently used service and AQL standard is the most common way to select a sample for visual or appearance review.

AQL refers to the maximum number of defective items that could be considered to accept during the random sampling of pre-shipment inspection. To reduce risk before accepting a shipment, AQL sampling is a practical and effective approach to undertake quality assurance on an order of produced items.

Generally, for clothing items 1.5%, 2.5%, and 4.0% AQL values are used depending on the type and price of the clothing.

Sampling with AQL yields results based on statistics, from which apparel importers can make more informed decisions about accepting or rejecting the goods.

Single Sampling Plans for Normal Audit (General Audit Level II)

Quantity in delivery | Sample size | Acceptable quality level | |||

2.5 | 4.0 | ||||

|

| Accept | Reject | Accept | Reject |

2-8 | 2 | 0 | 1 | 0 | 1 |

9-15 | 3 | 0 | 1 | 0 | 1 |

16-25 | 5 | 0 | 1 | 0 | 1 |

26-50 | 8 | 0 | 1 | 1 | 2 |

51-90 | 13 | 1 | 2 | 1 | 2 |

91-150 | 20 | 1 | 2 | 2 | 3 |

151-280 | 32 | 2 | 3 | 3 | 4 |

281-500 | 50 | 3 | 4 | 5 | 6 |

501-1200 | 80 | 5 | 6 | 7 | 8 |

1201-3200 | 125 | 7 | 8 | 10 | 11 |

3201-10000 | 200 | 10 | 11 | 14 | 15 |

10001-35000 | 315 | 14 | 15 | twenty one | twenty two |

Click here to learn: How to Read AQL Table?

Guidelines for Suppliers

- Ensure that the products to be inspected are all located in the same facility

- Ask your supplier to confirm an inspection date in advance. The inspection should be performed at least 5 working days prior to the shipment date

- Test equipment/facilities should be available to enable inspectors to properly evaluate function, performance, and overall compliance with specifications at the time and place of audit

- Must assign a competent person to communicate, coordinate, evaluate, assist, and take the necessary corrective actions that may arise during the inspection procedure

- Must have a proper environment (proper light, clean table) in order to conduct the inspection

- Must have packing list, spec sheet, purchase order, approved sample of the articles to be audited

- All the cartons must be sealed, sorted by article and be held in a visible clean neat area

Get in touch with us to learn more about our prices.

Guidelines for Quality Inspection Agency ( TESTCOO Inspection )

- Promptly confirm the inspection date and location and avoid delays

- Clarify inspection requirements like sampling method, work instructions, special requirements, etc

- Send inspection files requiring the detailed packing (color, ratio and quantity per carton), required packing depends of the quantity, style, and design

- Document requiring measurements of the final products

- Specify your checklists and inspection protocols

- Align with the inspector on what defects they can and cannot accept, classified as minor, major and critical

TESTCOO's Quality Control Services in India

TESTCOO has been present in India as a well-known third-party inspection agency since 2017. Our nationwide network of qualified and highly trained inspectors and engineers allows us to offer professional quality solutions with early production, during production or final pre-shipment inspection.

In India, TESTCOO offers product inspection and auditing services to both local and international clients across production hubs, including Delhi, NCR, Jaipur, Jodhpur, Panipat, Moradabad, Ahmedabad, Tirupur, Bangalore, Mumbai, Kolkata, Damanand other regions.

We specialize in product quality inspection and factory audit for all types of apparel and textile , fabric , shoes , furniture , kitchenware and tableware , toys , lighting , home appliances , consumer electronics and medical device .

To learn more about our product quality inspection service in India and preparation for your inspection checklist, contact our experts at service@testcoo.com to discover the solutions.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

Quality Control, Inspection Services in China

Quality Control, Inspection Services in China How Should Traditional Inspection Industry Transit In Industrial 4.0 Era

How Should Traditional Inspection Industry Transit In Industrial 4.0 Era How Do We Make 1+1 More Than 2. Testcoo Knows

How Do We Make 1+1 More Than 2. Testcoo Knows Valentine’s Inspection Knowledge

Valentine’s Inspection Knowledge Starting Your Importing Business From China (Part 1)

Starting Your Importing Business From China (Part 1) Time To Worry About Your Partner Factory

Time To Worry About Your Partner Factory Xiaomi In No Hurry For International Expansion

Xiaomi In No Hurry For International Expansion Critical Rise Imported Car Sales In South Korea

Critical Rise Imported Car Sales In South Korea Boeing is building its first overseas factory in China

Boeing is building its first overseas factory in China “315 Evening Gala”——Savior of China’s Quality Issues

“315 Evening Gala”——Savior of China’s Quality Issues