Supplier Assessment

Conducting a supplier assessment before and during your cooperation with a supplier in China, India, Vietnam, or elsewhere in Asia, will not only help to make sure that they are the right partner, but also that they are capable of maintaining the standards that you require over time.

It’s often that we must be made aware of an effective way to validate that your vendors are who they say they are, especially if your suppliers are far from China and Southeast Asia. You need to source a reliable and efficient supplier for your products and don’t have time to waste on the wrong kind of supplier.

Conducting a supplier assessment before and during your cooperation with a supplier in China, India, Vietnam, or elsewhere in Asia, will not only help to make sure that they are the right partner, but also that they are capable of maintaining the standards that you require over time.

We provide factory Assessment in China, Vietnam, India, and elsewhere in Asia, Europe, the Americas, and Africa.

What is a Supplier Assessment?

Supplier assessment is gathering specific information about suppliers and their business through the on-site inspection of suppliers.

TESTCOO’s auditor qualifies or disqualifies a potential supplier based on legitimacy, qualification, main products, main production processes, production capacity (including the number of equipment, the number of personnel, the area of the site), research and development capabilities, market experience, basic supplier management practices, basic quality management practices, basic social responsibility management practices, account information, etc. before you start working with them.

How does TESTCOO Conduct a Supplier Assessment?

TESTCOO conducts a supplier assessment as the following aspects:

- Basic Information.

- Human Resource.

- Production Procedure and Capacity.

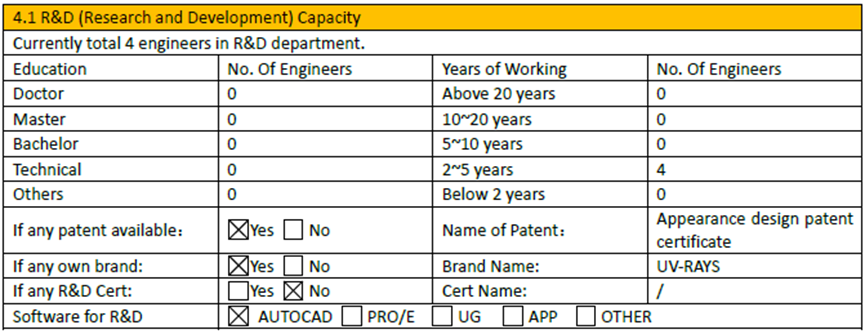

- Research and Development.

- Quality Management System.

- HR Management and Work Environment

- Environment Production

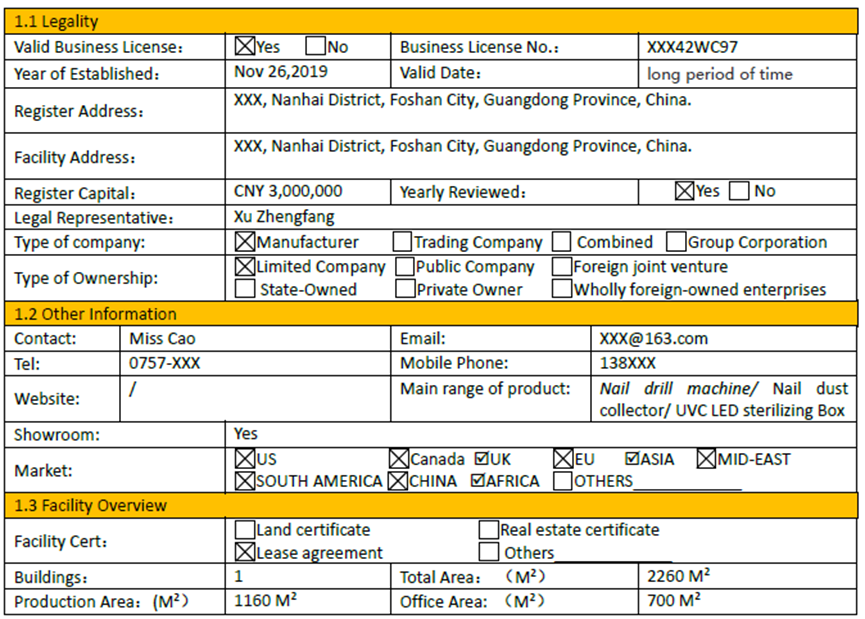

1. Basic Information

We check existing local-language legal documents about the supplier. We gather some basic information that is usually sufficient to confirm whether a company is likely to be a manufacturer (rather than an intermediary), what product types they are authorized to work on, and who the owner(s) are and to verify what they said is true.

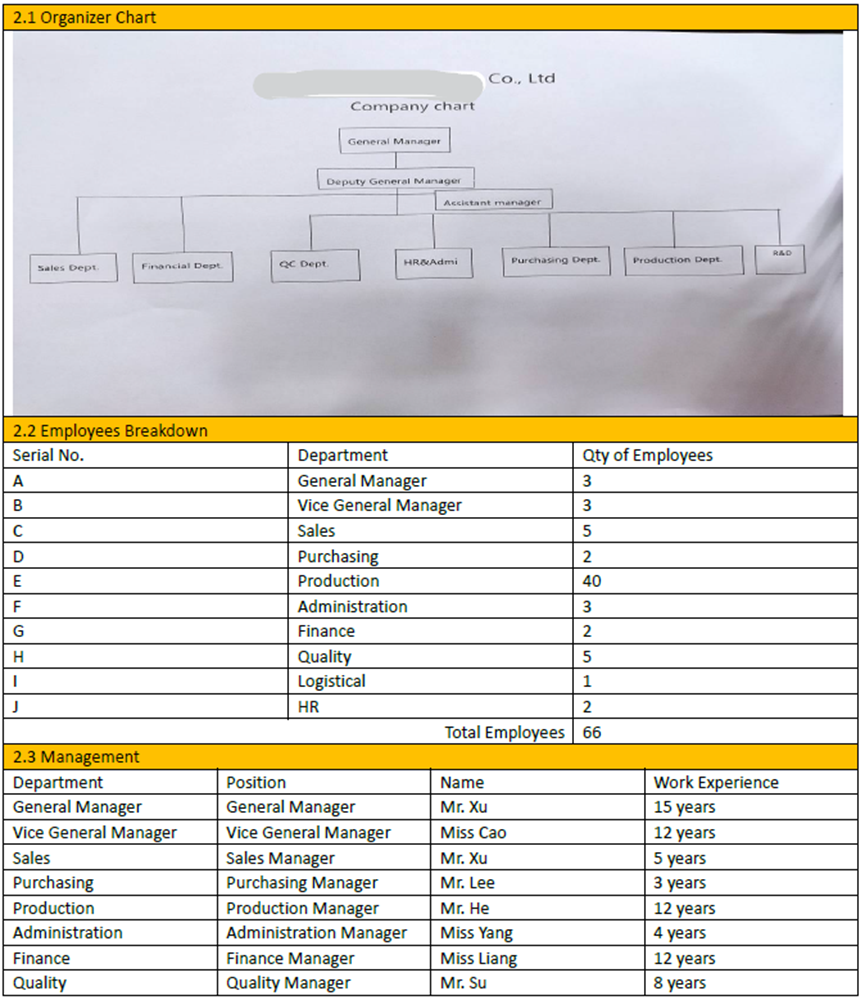

2. Human Resource

We check human resources of the supplier to verify whether the company's organizational structure complies with ISO 9001 standards.

3. Production Procedure and Capacity

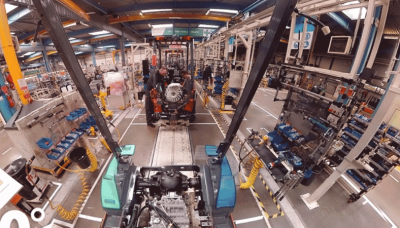

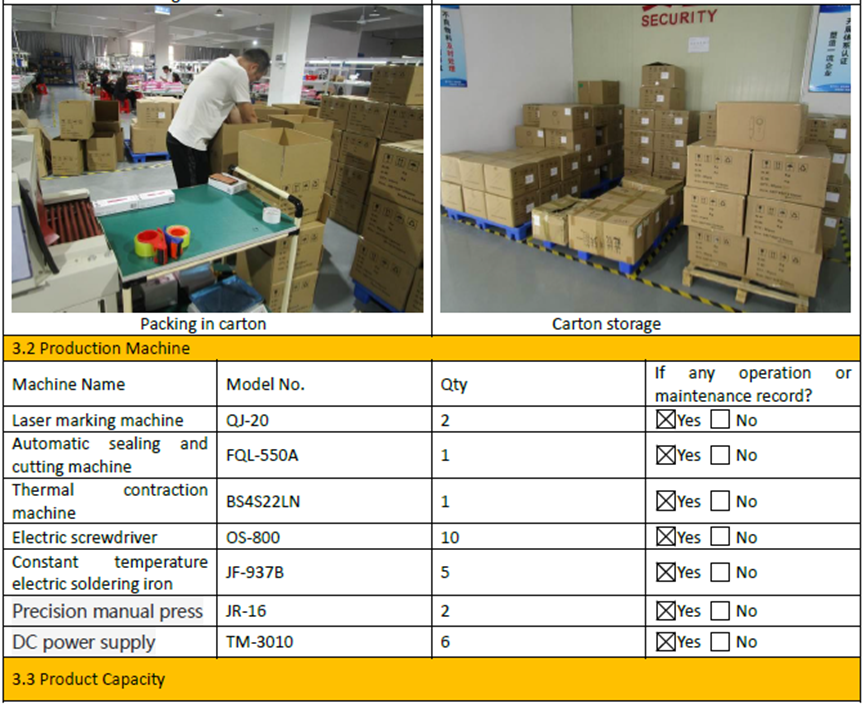

We check the production process, machine and product capacity to verify that your supplier's facilities are operational and suitable for manufacturing your product.

Any size of a factory you are considering working with where an understanding of whether their manufacturing organization and quality processes are what they claim them to be.

Note that we typically focus on a few processes, only for 1 product that you intend to purchase.

4. Research and Development

We check the research and development capacity for your new vendors to evaluate the potential development.

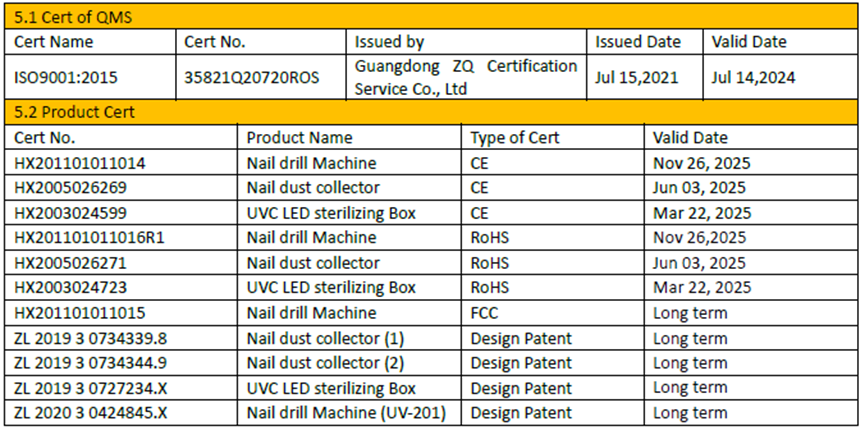

5. Quality Management System

We check the supplier certificates and products certifications to identify whether the supplier has an effective quality management system and ensure that the quality of products meets your expectations.

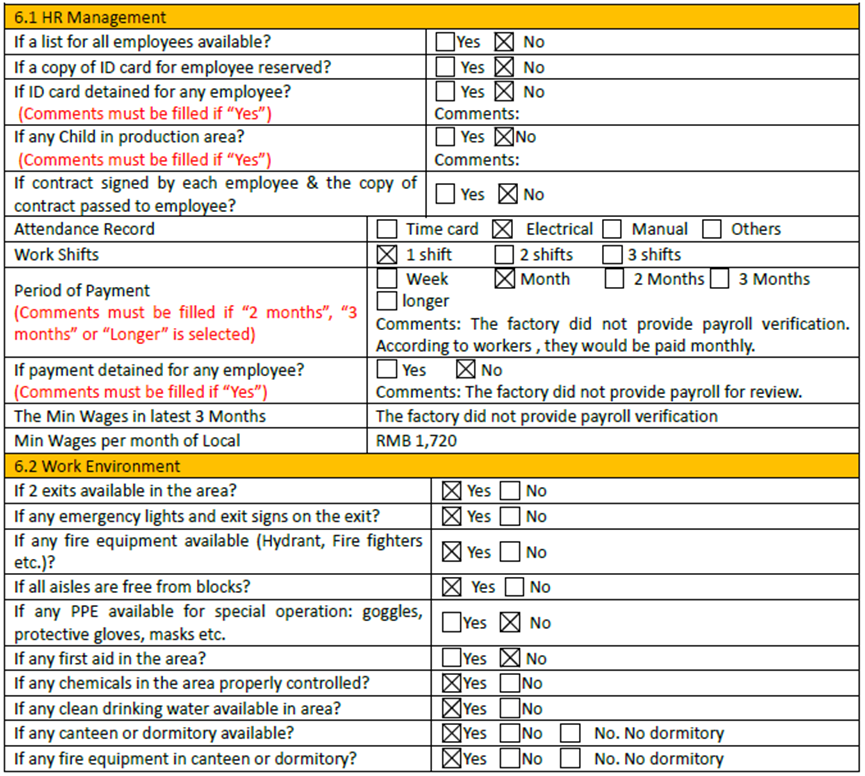

6. HR Management and Work Environment

We check HR management and work environment to assess working conditions and ensure no human rights violations occur, such as child labor.

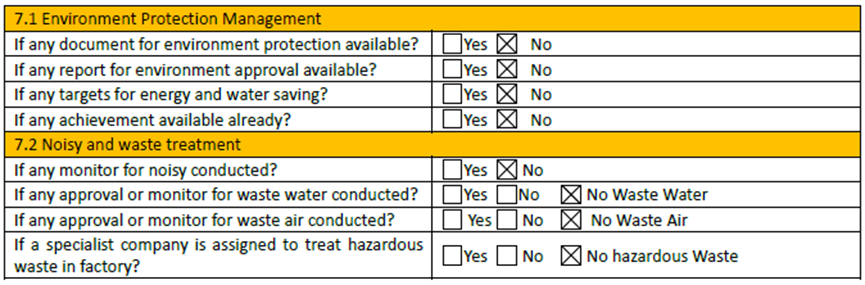

7. Environment Production

We check environment production management and noisy and waste treatment to verify whether the factory complies with environmental standards and requirements.

What is the Process of a Supplier Assessment Performance

The process of a supplier assessment includes: opening meeting, on-site assessment, document review, close meeting, and report writing. Auditor visits the factory at a certain time as agreed.

1. Opening Meeting

Ask the relative people including HR, production manager, and quality manager come and have the opening meeting. The content of the opening meeting is as follows:

Explain the purpose of assessment.

The scope of the assessment area, and the requested documents.

The photo request of audit area and documents, and any other support.

2. On-site Assessment

-Check the factory whole scan, factory gate, buildings, office, showroom, and take photos.

-Visit material warehouse and accessories warehouse, and take photos. Check the materials storage material identification such as IQC records and labels. Check if the material stored in a reasonable way.

- Check the semi-products and final products area. It is the same story as the checking in the material warehouse.

3. Documents Review

Ask factory to provide the relative legal documents such as business license, Imp & Exp license, production license, etc., and make sure it is the requested assessment factory.

4. Closing Meeting

Explain to the factory representatives the findings during the audit, and ask factory if any feed backs or explanations.

5. Report Writing

Write report according to the materials and photos collected from factory.

Why Perform a Supplier Assessment?

Our focus is on assuring that your suppliers are legitimate (no scams) and have their stories straight.

Any importer should conduct a supplier assessment on a potential new supplier, to conform that they fit your needs, or to assure that a current supplier is improving.

A supplier assessment help you verify your new vendor is not a fraud, reduce the risk of you working with a supplier who, ultimately cannot get your goods done at the cost, quality, and within the timescale, you’re expecting.

When Should You Conduct a Supplier Assessment?

Importers generally choose to conduct supplier assessment as a Final Step When Qualifying New Suppliers.

When going through the sourcing process, you likely identify several suppliers that can manufacture your product. Then, after evaluating them in various ways and getting product samples, you narrow them down to one.

That supplier may seem to meet your production, quality, and delivery requirements on paper. They may offer reasonable pricing and produce superb samples — but before you sign on the dotted line, you can conduct a supplier assessment to be sure they’re not misleading you.

Hiring a third party (like TESTCOO) to provide supplier assessment services will help you assess their capabilities and capacity. With the information you collection, you’ll have the confidence to determine whether to place an order.

How much does a Supplier Assessment Cost?

We charge 249 USD per man-day in major areas of China (and extra travel expenses apply in other places).

We charge 299 USD per man-day in Vietnam, India, Cambodia, Pakistan, Bangladesh, Philippines, Indonesia, Malaysia, Thailand, Turkey, and Myanmar.

Ready to get started on finding your new supplier?

Conclusion

If you are afraid of working with suppliers who can’t deliver as promised, a factory audit helps you to evaluate their capability and capacity, as well as the maturity of their systems. It highlights key risks that might prevent them from meeting your needs, allowing you to make an informed decision on whether to work with them or not and/or forming the basis of an improvement plan.

TESTCOO helps conduct supplier assessment to qualify the potential suppliers. Supplier assessment represents one of the most important decisions in a company to remain competitive, especially in times like now when markets are changing very fast.

Get in touch with us to find the factory audit solution.