Safety Management: Requirements for Spot Inspection of Labor Protection Articles

Labor Day is coming soon, people will celebrate this day in honor of our hard work, and it is true that laborers all over the world are well worthy of respect for sure. Especially in China, the government will organize a 5-day holiday this year.

Yet the manual laborers are the most lovely people in the world, they donate their hard work by hand day by day, year after year. However, many accidents and unexpected dangerous conditions may happen every day, and we can not avoid this incident happening, but we can try our best to do something to prevent this from frequent happening. Preparing safety clothing and labor protection articles for manual laborers is obviously necessary and important to order to effectively protect the manual workers. However, during routine using, we may find many labor protection articles may have a lot of problems either the outside appearance or the inner material parts. Therefore, it is critical to do some labor protection article quality inspections before purchasing them. And it is indeed a very important step among the complete labor safety management.

And during the whole spot inspection process, there may appear some important requirements we need to follow, and of course, high-quality inspection services rise in response to the proper time and conditions to meet with customers’ needs for various hardlines inspection! This article will simply and clearly demonstrate some detailed requirement points and share some specific commonsense and industrial rules for you:

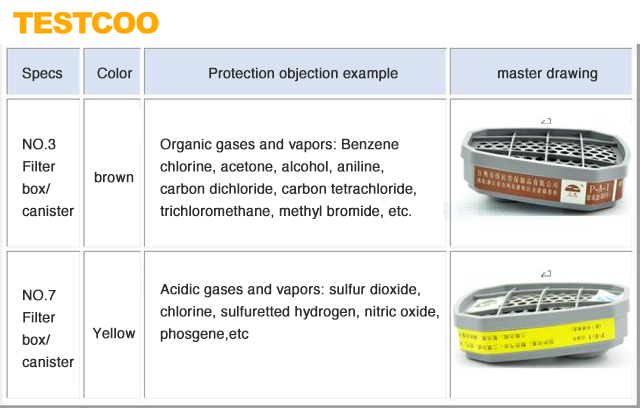

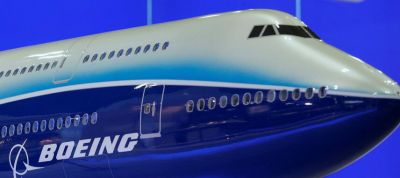

Ⅰ. gas mask (full, half mask, filter box) spot inspection requirements

1. The selection of gas mask and filter box should conform to the requirements of on-site protection;

2. Gas mask and filter box should be matched and firmly connected;

3. Check whether there are cracks on the surface of the gas mask and make sure that the mask is tightly fitted to the face to ensure good air tightness;

4. The actual opening date of the filter box should be filled in for trace ability, and it should be replaced six months after opening;

5. Check whether the breathing valve of the muzzle and nose mask is deformed, whether the elasticity is normal, and whether there are cracks and cracks;

6. Check whether the sealing plug of the filter box is in good condition and whether the time of the filter tank exceeds the effective use period;

7. Gas mask, filter box appearance should be clean without stains;

Ⅱ. Point inspection requirements for chemical defense clothing (Grade A /B /C /D)

1. Before spot inspection, wear undamaged PVC gloves;

2. Check the chemical clothing cloth, check whether he appears cracks, cracks or fiber coating peeling, if this situation should be replaced immediately chemical clothing;

3. The appearance of chemical protective clothing is clean and without stains, and no unknown liquid remains;

4. Chemical clothing accessories are complete;

5. If the protective clothing is damaged during use or storage or exceeds the effective use period, it shall be regarded as invalid and replaced in time.

Ⅲ. heat insulation clothing inspection requirements and matters needing attention

1. Check whether each part of the surface layer of the heat insulation suit is intact, and whether the inner heat insulation layer and comfort layer are orderly;

2. High temperature resistant pants, high temperature resistant shoe cover, high temperature resistant shirt, high temperature resistant head cover, high temperature resistant gloves, carefully check the size of each part after wearing the heat insulation clothing is appropriate, can cover the exposed parts completely, each part lock is buckled.

3. It is strictly forbidden to soak and beat the complete set of flame retardant heat insulation suit with water, and it must be kept dry;

4. Try to hang the clothes to avoid damaging the clothes after folding for many times and affecting the overall protective performance;

5. Check whether the hood screen is damaged and whether the line of sight is clear.

Ⅳ. Requirements and matters needing attention for spot inspection of safety helmet

1. Check whether the appearance of the helmet has cracks, bruises, bumps and bumps, and wear, whether the hat liner is complete, whether the structure of the hat liner is in a normal state, and if there are obvious defects affecting the performance of the helmet, it will be scrapped in time, so as not to affect the protective effect;

2. Do not remove or add accessories to the safety helmet at will, so as not to affect its original protective performance;

3. Attention should be paid to the use of safety helmets within the validity period. The validity period of plastic safety helmets is two and a half years, and the validity period of glass reinforced plastic safety helmets is three and a half years. ;

4. Observe the safety helmet appearance intact, no damage, no deformation, lining intact;

5. There should be a gap of 2-5 cm between the cap shell and the cap lining;

6. The safety helmet that has undergone a shock or test shall be scrapped and cannot be used again;

7. When using the helmet, the wearer must wear it properly and firmly, and not shake it. The lower jaw band should be fastened, and the back hoop should be adjusted to prevent the helmet from falling off.

8. Do not collision helmet, do not sit helmet bench, so as not to affect its strength.

9. The safety helmet can not be stored in the environment polluted by acid, alkali or chemical reagents, can not be placed in high temperature, sun or damp places, so as not to aging deterioration.

Ⅴ. Safety belt spot inspection requirements and precautions

1. Components are in good condition, without shortage or damage;

2. Rope, braided belt without brittle crack, broken or kink;

3. Leather accessories are intact;

4. Metal fittings without cracks, welding defects, no serious corrosion;

5. The bite of the hook tongue of the hook hook is smooth without dislocation, and the safety device is complete and reliable;

6. The living beam clamp is flexible and the surface knurling is good.

7. Rivet without obvious deviation, smooth surface;

8. The adjustment devices of leggings and belts of safety belts are qualified and effective.

To accomplish the complicated testing process listed above, you surely need to entrust those very experienced and professional inspectors. But how to choose those best inspectors and make your inspections efficient and standard? You need to pick up one trustworthy test-service company. Among many test-service companies, Testcoo is one great company you can trust, it offers you very competitive price, fast case pick-up, efficient inspector appointment, multiple inspection method choices , online APP check, real-time AR immersion check and communicate service, etc.

Thus we recommend Testcoo to you for your labor protection article inspection demand. Choosing Testcoo will enable your safety management more efficient and secure!

For more you want to know about the labor protection article inspection, please click here: https://www.testcoo.com/en/Hardlines_Inspection.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

Quality Control, Inspection Services in China

Quality Control, Inspection Services in China How Should Traditional Inspection Industry Transit In Industrial 4.0 Era

How Should Traditional Inspection Industry Transit In Industrial 4.0 Era How Do We Make 1+1 More Than 2. Testcoo Knows

How Do We Make 1+1 More Than 2. Testcoo Knows Valentine’s Inspection Knowledge

Valentine’s Inspection Knowledge Starting Your Importing Business From China (Part 1)

Starting Your Importing Business From China (Part 1) Time To Worry About Your Partner Factory

Time To Worry About Your Partner Factory Xiaomi In No Hurry For International Expansion

Xiaomi In No Hurry For International Expansion Critical Rise Imported Car Sales In South Korea

Critical Rise Imported Car Sales In South Korea Boeing is building its first overseas factory in China

Boeing is building its first overseas factory in China “315 Evening Gala”——Savior of China’s Quality Issues

“315 Evening Gala”——Savior of China’s Quality Issues