Final Inspections: Crucial For Checking Product Quality Before Shipment

Final inspections done at random represent a unique chance to check the quantity, quality of finished products, and packaging and labelling before shipment. Unlike inspections during production, they’re performed quite near the shipment date after production is finished.

What are the risks of letting products ship without performing a final inspection?

Receiving defective products can leave you in a lot of trouble with unsellable products that will be very difficult to return and could even be unsafe for users. Once they’re with you there isn’t a lot you can do to put them right, the costs to sort and rework them in your country could be prohibitive and it’s really not possible to send defective products to China in any case, so you could be left having to scrap some or all of your shipment. Worst case for the manufacturer, they lose your custom. Worst case for you, angry customers, heavy financial losses, and, maybe, even legal issues or the threat of jail time for consumer safety issues.

What is a final inspection?

It’s likely a large proportion of the products are already packed in export cartons by the time the final inspection is done. The inspector will pick a certain number of pieces from cartons randomly and they will be focusing both on the product itself and on the packaging using their checklist that has checkpoints about aesthetics, function, safety features, labelling, etc. At this point, they may well have an approved ‘golden sample’ in hand, too, for reference.

A danger includes an inspector not picking a representative sample of products at random, such as when a factory provides the cartons to be checked in advance to ‘save time’ for the inspector. In this case, the final inspection report is only based on products that the factory has put forward, not the entire batch. This gives ample opportunity to hide defects and errors.

When are final inspections usually performed, and why?

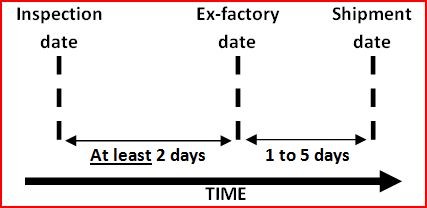

An inspection that is earlier during production is good for catching issues, but a final random inspection needs to occur once 100% of the products are made and when most products (around at least 80%) are packed. By doing so the cartons can be counted, the representative quantity can be estimated, and the export and retail packaging can be checked against the checklist. The buyer needs to insist on a plan, where timelines for the inspection are clear. If not enough time is provided for the inspection and follow-up actions, if issues are found, before the shipping date, this could cause all kinds of problems.

A typical timeline might look like this:

Where should the final inspections take place and who does it?

In most cases, they occur at the manufacturer’s facility as the goods have only just been packed. Sometimes it may be in a separate warehouse, but this is a possible red flag as a separate location like this can be used by trading companies to obscure where the manufacturing actually takes place.

Benefits of doing them in the manufacturing facility include being able to give live feedback about defect types, processes, etc, to the manufacturer’s quality and production teams that helps train them to correct mistakes and improve the job they’re doing.

When choosing who should do the inspection, relying on the supplier’s own inspection is not advisable in most cases as the supplier may have their own interests in mind when reporting issues to you (or not).

You may choose to do the inspection yourself if you’re able to travel to China/Asia to perform it, and this may make sense in limited cases where defining defects are quite subjective (such as in the case of new products that are weathered to make them look older). However, in most cases it makes sense to employ a local inspection agency who is experienced in your product category, speak the language, etc, to perform it for you as that’s usually far easier and cost-effective than flying team-members out to China (even if you were able to do so). TESTCOO, for example, have been supporting customers with suppliers in China and across Asia with their product inspections for over 7 years.

What are the unique benefits of a final inspections in comparison to earlier product inspections?

It’s the only time when you can count the quantity, check packaging and labelling, and check samples of finished products (inspections during production may in some cases be on components that haven’t been assembled into finished products yet) at random at the same time. If issues are found, bad products can be sorted out and reworked if possible, assuring that only correct products are shipped to you.

Drawbacks include a lack of time to make changes before the products need to be shipped due to the inspection being close to the shipping date. Also, manufacturers may baulk at the cost of putting things right and refuse, leaving importers to either accept shipment of defective products or, maybe, receive nothing at all because they are under time pressure to deliver to their own customers. They are put in a position where they have to choose to ship poor quality products on time which sets a dangerous precedent with the manufacturer.

A final inspection alone could be fine for trustworthy and reliable suppliers who have been making the same products for some time, but for new suppliers, those making unfamiliar new products, or suppliers who’ve proven to be unreliable, performing only the final inspection is a risk and should be done in complement to earlier product inspections during production, too (especially if you’re dealing with large batches and large amounts of money at stake).

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

Quality Control, Inspection Services in China

Quality Control, Inspection Services in China How Should Traditional Inspection Industry Transit In Industrial 4.0 Era

How Should Traditional Inspection Industry Transit In Industrial 4.0 Era How Do We Make 1+1 More Than 2. Testcoo Knows

How Do We Make 1+1 More Than 2. Testcoo Knows Valentine’s Inspection Knowledge

Valentine’s Inspection Knowledge Starting Your Importing Business From China (Part 1)

Starting Your Importing Business From China (Part 1) Time To Worry About Your Partner Factory

Time To Worry About Your Partner Factory Xiaomi In No Hurry For International Expansion

Xiaomi In No Hurry For International Expansion Critical Rise Imported Car Sales In South Korea

Critical Rise Imported Car Sales In South Korea Boeing is building its first overseas factory in China

Boeing is building its first overseas factory in China “315 Evening Gala”——Savior of China’s Quality Issues

“315 Evening Gala”——Savior of China’s Quality Issues